High Quality Oil Free Scroll Vacuum Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Oil Free Scroll Vacuum Pumps

1.Structure of Oil Free Scroll Vacuum Pump

single stage rotary vane vacuum pumps combining with many years of experience in vacuum engineering and the latest international vacuum technology developed to meet requirements of both the industry and the environment.They are being used in all areas of vacuum engineering. They are equally suited for both industrial production and research applications. They may be used to generate a rough and medium vacuum or as backing pumps in pump combinations with Roots pumps or high vacuum pumps. The comprehensive range (pumping speeds ranging from 10 to 630 m 3 / h) allows every customer to select the right pump for his particular needs.

2.Main features of Oil Free Scroll Vacuum Pump

• Long life design

• The comprehensive range from 10 to 630 m 3 / h

• Vacuum pump entirely replace the pumps like U3/U4,R5,VC,EU and etc.

• High pumping speed also at low pressures

• Optimum price-to-performance ratio

• Low noise level

• Low vibrations

• Integrated exhaust filter, up to 99.9% efficient

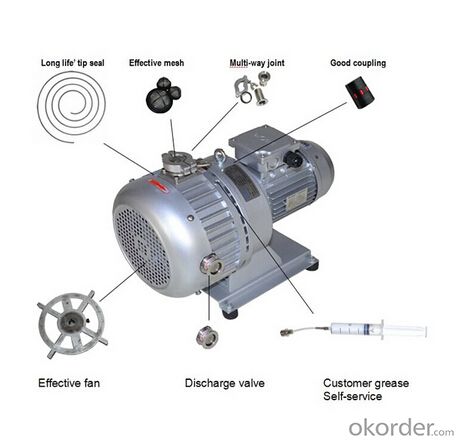

3.Oil Free Scroll Pump Images

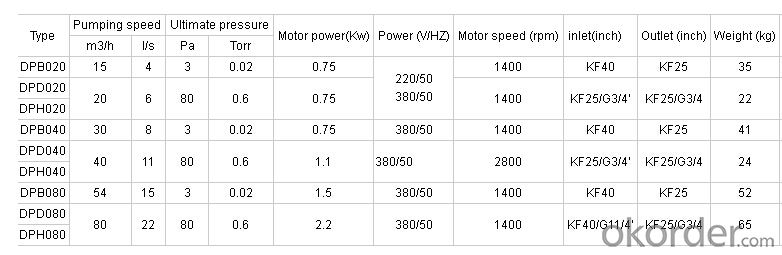

4.Oil Free Scroll Vacuum Pump Specification

5.FAQ

①Application

Food industry , Vacuum packaging, Material drying, Car industry , Furnaces and plants , chemical, Laser technology , Medicinal technology , Metallurgy , Power engineering , Space simulation , Vacuum coating , vacuum loading, electronics, semiconductor, scientific research

- Q: How to adjust the flow of piston pump?

- Changing the size of the current in the solenoid valve can change the angle of the tilting element, and then change the stroke length of the plunger in the pump cylinder, that is to say, to change the flow of the pump. An inclined angle is called a quantitative pump, and the angle of inclination can be changed, which is called a variable pump.

- Q: Fire pump and shower pump flow head selection, high resolution.

- 3, larger than 25000, the minimum water consumption of indoor fire hydrant is 20L/s4, the minimum water consumption is the flow of a fire hydrant.

- Q: Rotary vacuum pump does not meet the requirements of vacuum, what are the reasons?

- (1) the disk, stator or bushing is worn and shall be inspected, trimmed or replaced with a rotary vane vacuum pump.(2) the pump temperature is too high, which not only reduces the viscosity of the oil, increases the saturated vapor pressure, but also may cause cracking of the pump oil. Ventilation, cooling and environmental temperature should be improved. If the exhaust gas temperature is too high, should be cooled before entering the pump, the environment temperature is high, should try to use a better high speed vacuum pump oil or 3# diffusion pump oil. (10) because of the deformation, wear or movement of the parts, the maximum opening height of the check head can be reduced or even unable to be opened, the intake of oil is too little, and the vacuum degree of the rotary vane vacuum pump is reduced, and should be adjusted as shown in the assembly section. Open high, more oil, but open too high, check valve in some places on the stop, it will not automatically drop, lost to prevent oil returns. The commonly used rotary vane vacuum pumps mainly include double stage rotary vane vacuum pump and single-stage rotary vane vacuum pump

- Q: How does the centrifugal pump pump and cut the pump?

- Turn on the motor, observe the motor current, turn from high to low, observe the pump outlet pressure, and the pressure rise;Slowly open the outlet valve, so that the pressure drop slowly, the current slowly rising to the stable, the outlet valve to the maximum;Check the pump operation, stuffing box leakage, current, whether or not the rated current, motor, bearing temperature is normal, whether or not abnormal sound.

- Q: How much water does the water ring vacuum pump run for an hour? If there is no steam separator, does the water vaporize?

- For example: water storage is relatively small, it needs to reduce the temperature of the heat exchanger. If the tank is relatively large, it does not need cooling water circulation pump again when the temperature is very low, there is no need to heat exchanger. So you need to ask how much water this is not OK.In a soda separator problem:

- Q: What are the characteristics of a pipe shield pump?

- According to the transmission of liquid temperature, pressure, viscosity and particle level have different requirements, the pump can be divided into the following types: first, the basic type (standard type) transport medium temperature does not exceed 120 degrees, the head of not more than 100m, the pump other types are variations on the basic type and improved.

- Q: There are second cutting, third cutting, why three times?

- There are 2 situations, first, for example, a XXXX-160 type pump head 32, flow 100, motor 15kW, according to the model we need to cut a become head 28, flow rate of 88, this time, in addition to cutting the impeller, the pump or the original pump motor, became 11kW this is, re designed a new model, namely XXXX-160A, but most structural components did not change. In the same way, we want to design a XXXX-160B that makes the head 24 and the flow rate 80, then we just need to cut the impeller again and match the smaller (7.5kW) motor (the motor bracket needs to be redesigned). In general, multiple cutting impellers are designed to expand and enrich the model. Second, the actual use, if you think the flow head is too large, but also can be cut to make it smaller to adapt to practical applications. But the 2 and 3 cuts you ask are the first.

- Q: What are the basic technical parameters of the pump?

- The effective power of pump and output power, with Pe said. It is the effective energy per unit time from the pump in conveying out liquid obtained in the pump. Because the lift refers to the effective energy, pump output unit of heavy liquid obtained from the pump so that the product of head and the mass flow rate and the acceleration of gravity. Is to obtain the output from the pump in unit time of liquid effective energy - efficient pump power: Pe= P gQH (W) = QH (W) - P - density of liquid pumping (kg/m3); severe gamma - pump for transporting liquid (N/m3) - Q (pump flow; m3/s; H) - pump head (m); G (m/s2). The acceleration of gravity P axle power and effective power Pe is the difference of power loss in the pump, the size of the pump efficiency to measure the efficiency of the pump. As the effective power and shaft power ratio, with ETA said. Selection of related pumps:

- Q: What are the problems that should be paid attention to when using vacuum pumps?

- (8) in the process of running the pump, the bearing temperature shall not exceed the ambient temperature 35C, and the maximum temperature shall not exceed 80C.(9) if the abnormal sound of the vacuum pump is found, the reason should be stopped immediately.(10) vacuum pump to stop using, first shut down valve, pressure gauge, and then stop the motor. (11) vacuum pump in the first month of work, 100 hours after the replacement of lubricating oil, oil every 500 hours after the change.(12) adjust packing gland regularly to ensure the normal condition of drip in packing room. (13) regular inspection of shaft sleeve wear, larger wear should be replaced in good time.

- Q: What is the distance between the pump and the wall?

- What do you mean by that? If your pump is parallel to the wall! Then, the wall of the pump near the wall is usually 500mm. This is an empirical data, considering the import pipe length, pump maintenance and motor heat dissipation and other aspects of the situation to determine. Dozens of pumps installed in our company are placed in this size! Hope to be of help to you.

Send your message to us

High Quality Oil Free Scroll Vacuum Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords