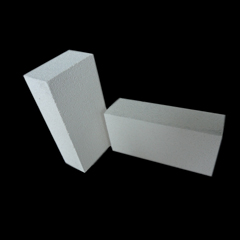

High Quality Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

CMAX insulating firebricks are classified under temperature

between 1100℃ to 1700℃, manufactured from high purity alumina

clay.

Quick Details

| Place of Origin: | Shape: | Material: | |||

| Model Number: | Brand Name: | brick: |

Packaging & Delivery

| Packaging Detail: | wooden pallet |

| Delivery Detail: | in 30 days |

Specifications

1.NG series clay insulation brick

2.Bulk Density:0.6,0.7,0.8,0.9,1.0

4.STD size:230 x 114 x65 mm

Product Index | NG-1.0 | NG-0.9 | NG-0.8 | NG-0.7 | NG-0.6 |

Bulk density g/cm3 | ≤1.0 | ≤0.9 | ≤0.8 | ≤0.7 | ≤0.6 |

Cold crushing strength kg/cm2 | ≥35 | ≥25 | ≥25 | ≥25 | ≥20 |

Permanent linear change temp. | ≥1350 | ≥1300 | ≥1250 | ≥1250 | ≥1200 |

Thermal conductivity 350oC±25 W/m·k | ≤0.5 | ≤0.4 | ≤0.35 | ≤0.35 | ≤0.25 |

- Q: Do insulating fire bricks require any special curing or firing process before use?

- No, insulating fire bricks do not require any special curing or firing process before use. They are ready to be used as soon as they are installed.

- Q: Can insulating fire bricks be used to build pizza ovens?

- Indeed, pizza ovens can be constructed using insulating fire bricks. These bricks are specifically designed to endure high temperatures and offer exceptional insulation, rendering them a suitable choice for pizza oven construction. With their low thermal conductivity, these bricks aid in retaining and evenly distributing heat throughout the oven. The insulating qualities of the bricks facilitate the attainment and maintenance of the desired temperature, ensuring efficient and consistent pizza cooking. Moreover, the lightweight nature of insulating fire bricks simplifies handling and installation during the construction process. All in all, due to their capacity to withstand high temperatures and provide efficient insulation, insulating fire bricks prove to be an excellent option for pizza oven construction.

- Q: Are insulating fire bricks fireproof?

- Yes, insulating fire bricks are fireproof. They are designed to withstand high temperatures and provide insulation to prevent heat transfer. Insulating fire bricks are made from refractory materials that have a high melting point and can withstand extreme heat without melting or crumbling. They are commonly used in applications where high temperatures are present, such as kilns, furnaces, fireplaces, and ovens. Insulating fire bricks are an excellent choice for fireproofing as they offer excellent thermal insulation properties and can effectively protect against the spread of fire.

- Q: Can insulating fire bricks be used in wood-fired kilns?

- Yes, insulating fire bricks can be used in wood-fired kilns. Insulating fire bricks are specifically designed to withstand high temperatures and provide insulation, making them suitable for use in wood-fired kilns where temperatures can reach extreme levels.

- Q: Are insulating fire bricks suitable for insulation in boilers?

- Yes, insulating fire bricks are suitable for insulation in boilers. Insulating fire bricks are specially designed to withstand high temperatures and provide excellent thermal insulation, making them ideal for use in boilers. They help to reduce heat loss, improve energy efficiency, and enhance the overall performance of the boiler.

- Q: Can insulating fire bricks be used in chimneys or flues?

- Insulating fire bricks are not recommended for use directly in chimneys or flues. While these bricks are designed to withstand high temperatures, they are primarily used for insulation purposes rather than as a structural component. Chimneys and flues require bricks that are specifically engineered to withstand the intense heat and corrosive byproducts of combustion. These bricks, known as refractory bricks, are designed to have high thermal resistance and exceptional durability to ensure the safe and efficient operation of the chimney or flue. Therefore, it is advisable to use refractory bricks instead of insulating fire bricks when constructing or repairing chimneys and flues.

- Q: Are insulating fire bricks resistant to carbon monoxide?

- Yes, insulating fire bricks are resistant to carbon monoxide.

- Q: Are insulating fire bricks resistant to weathering or aging?

- Insulating fire bricks exhibit exceptional resistance to weathering and aging. These bricks are specifically engineered to endure extreme temperatures and harsh environmental conditions. They are composed of top-notch refractory materials, including alumina, silica, and other additives, which confer exceptional thermal insulation properties and strong resistance to corrosion and erosion. The manufacturing process of insulating fire bricks entails meticulous selection of raw materials and precise control of firing temperatures, resulting in a dense and homogeneous structure. This structure effectively prevents moisture and other weathering agents from infiltrating, thus ensuring extended durability and resistance to aging. Moreover, insulating fire bricks are also highly resistant to thermal shock, enabling them to withstand rapid temperature fluctuations without fracturing or disintegrating. This characteristic bolsters their ability to withstand adverse weather conditions. All in all, insulating fire bricks have demonstrated remarkable dependability in diverse applications that involve exposure to weathering elements. They find widespread usage in industries such as steel, ceramic, glass, and cement manufacturing, as well as in high-temperature applications like kilns, furnaces, and chimneys.

- Q: Can insulating fire bricks be cut to size?

- Indeed, it is possible to alter the dimensions of insulating fire bricks. Usually composed of lightweight refractory substances like expanded clay or vermiculite, insulating fire bricks are quite manageable to cut. Saws or knives are sufficient tools for this task. It is crucial to bear in mind that precautions should be taken while cutting insulating fire bricks to ensure safety. Wearing protective goggles and a dust mask is recommended due to the potential dust and small particles generated during the cutting process. Furthermore, it is advisable to either refer to the manufacturer's instructions or seek professional guidance to guarantee the correct technique and tools are employed for cutting insulating fire bricks.

- Q: How do insulating fire bricks affect the overall cost of a project?

- Insulating fire bricks can potentially increase the overall cost of a project due to their higher initial price compared to regular fire bricks. However, they can also lead to long-term cost savings by improving energy efficiency and reducing heat loss, resulting in lower energy consumption and operational expenses.

Send your message to us

High Quality Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords