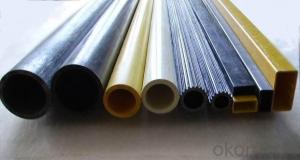

High Quality Composite Fiber Glass FRP Pipe Rod

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP Fitting, a wide range of fittings as elbows, reducers, tees, caps, flanges etc. is available.

Fittings are manufactured by the hand lay-up, contact molding and spray-up process. In hand lay-up and contact molding processes veil and alternate layers of mat and woven roving saturated with resin are applied on the mold. In spray-up process continuous strand roving is fed through a chopper gun, combined with catalyzed resin, and sprayed onto the mould surface.

CHARACTERISTICS

High anti-corrosion capability, long designed service time of 20 years;

2. Good hydraulic property, smooth inner surface with absolute roughness of 0.01mm, which is far less than that of carbon steel pipe or cast iron pipe;

3. Lightweight and facility to install and transport;

4. High specific intensity and reliable mechanical performance;

5. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid;

6. Less joints and rapid assembly design: According to concrete engineering conditions, there are a several

ways of connection designed for clients to choose, which include Adhesive-bonded Plug Joint, Adhesive-

bonded End-to-end Joint, Flange Joint, Plug Joint with O-ring Gasket(with key-lock) and Thread Joint etc.

7. Good electrical insulation

8. Not rust, rot or corrode, not permeate, and without consequent pollution;

9. Anti-furring and vermiculate resistance;

10. Flexible design: the pipe can be designed on the shape and function according to its conditions of usage.

TECHNICAL DATA

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m 2 ) |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

PICTURES

- Q: How can I replace the valve on the water supply pipe?

- Steel flanges, three way pipe fittings and single disk connector is connected, immediately install three branch pipe valve, and will be closed fittings and valves at the bottom with concrete pier support, in order to timely restoration of water supply.

- Q: Do I need CCC certification for ventilated GRP?

- Of course, there is also used for air conditioning duct glass fiber reinforced plastic pipe, the thickness needs at least 25MM, lined with EPS insulation foam.

- Q: Underground garage inorganic glass fiber reinforced plastic wind pipe water out of the way?

- As basement ventilation, there are galvanized iron pipes. This kind of iron pipe ventilation pipe, in the steam condensation of weakness will be more obvious - iron sheet wall thin, internal and external temperature difference is more likely to appear.

- Q: Is there any ventilation duct made of glass fibre reinforced plastic in Baotou?

- Fiberglass pipeacid and organic glass steel fan shell with acid and alkali corrosion resistance, long service life, is mainly used in chemical, textile, printing, metallurgy, underground facilities for discharging corrosive gas places.

- Q: How is FRP ventilation pipe made?

- Coating moldingOn the surface of the mold, a transparent glass paper is fixed on the surface of the bread. When it is fixed, it is coated with a resin coating which has been adjusted. It should be even and not exposed. Then apply a layer of glass cloth and then coat with a resin coating. Each coated with a layer of resin is deposited a layer of glass cloth. The cloth lap to stagger and scraping, the outermost layer of ruibu glass surface should be coated with a layer of resin coating. After reaching the required thickness, and then deposited on the outer surface of the glass paper flatten the light pressure.

- Q: Pipe installation of glass fibre reinforced plastic pipe

- In the area, pipeline installation order system, small diameter and large diameter after the first, the first layer after layer, the first easy, first on the pipe rack even after the equipment, pipeline is connected with the machine principle is from the inside to the outside, in order to reduce the influence of welding stress on the installation precision of the machine, touch the mouth interior with the outdoor pipeline should stay outside.

- Q: How to open a DN300 port on the DN600 GRP pipe and install the DN300 gate?!

- Do not know the road of glass steel flange have, if any to buy different materials of cast iron flanges or PVCU flange on the same material, the three way behind the pipeline branch, so that the material market has purchased (ABS buy buy in the small town is not easy), the construction is convenient. If it is a glass steel pipe, pipe end cannot change, can only be used to bond the glass steel material, the pipe bonded on the flange is an arc for a plane is bonded with a cast iron pipe flange suggestions. Because the FRP material and most of the plastic are not bonded.

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- 3PE has some disadvantages. (1) the bending of the guiding hole and the protruding rock, pebble and gravel in the hole will cause friction and scratch to the relatively soft 3PE corrosion resistant layer. (2) 3PE coating using polyethylene heat shrinkable sleeve joint, the convex part of the concave or lap joint, which makes it easy to travel being scratched or pulled off lead. (2) 3PE corrosion protection layer has a strong electrical shielding, so that the cathodic protection current is difficult to reach the defects of corrosion protection layer, thus causing perforation corrosion.So, from the last century at the beginning of 90s, the United States developed Powercrete (s) Powder Concrete Anticorrosion structure, namely in the bottom of fusion bonded epoxy powder, sprayed with epoxy resin as main film-forming material, and adding a two-component epoxy coating for concrete, polymer concrete curing agent and other inorganic fillers. The coating is tough and wearable and can be used directly in FBE coated pipes to protect the pipe from damage during handling, directional drilling, crossing, etc..

- Q: Who knows, how is the glass reinforced septic tank connected with the municipal pipe?

- Septic tank (Hu, F, NCH) is the treatment of nightsoil and to filter precipitation equipment. The principle is that the cured material decomposes at the bottom of the tank, and the upper hydration object flows into the pipeline to prevent the pipe from clogging and has enough time to hydrolyze the solidified object (such as excrement and urine). Tank (septic) refers to the division of living sewage sludge, and anaerobic digestion of sludge structure of small structures.

- Q: Can FRP pipes be used in heating pipes?

- Glass steel pipe road does not belong to common heating pipe material.Heating pipe requirements are solid, high temperature, pressure, easy connection, convenient construction.Usually, heating pipes are made of steel and materials are more common.

Send your message to us

High Quality Composite Fiber Glass FRP Pipe Rod

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords