High Strength FRP Rods Fiberglass 10mm Rebar Composite Pipes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Rod Description

GFRP Rebar,FRP Rebar,GRP Rebar,glass fiber reinforced polymer rebar,low-weight rebar,all-thread rebar,anti-static rebar.

2. Main Features of FRP Rod

1) All-Thread FRP Bolt: The rod is threaded over the whole length, i.e. "All-Thread";

2) High Corrosion Resistance: The base materials used by the bolt are durable materials, and they are molded through the composite process. The life span is up to 100 years. They can be used as permanent support materials;

3) High Tensile Strength: The load is approximately double that of a steel bar with the same diameter;

4) Low Weight: The weight is only 1/4 that of a steel bar with the same diameter. Therefore, the labor intensity is greatly reduced, and the transportation cost is reduced at the same time;

5) Anti-static: It has no electrical conductivity, and no sparks will be produced when being cut. It is particularly suitable for high gas zones;

6)Non-flammable: It is non-flammable and has high thermal isolation;

7) Cuttability: It avoids damages to cutter heads, and does not delay excavation

3. FRP Rod Images

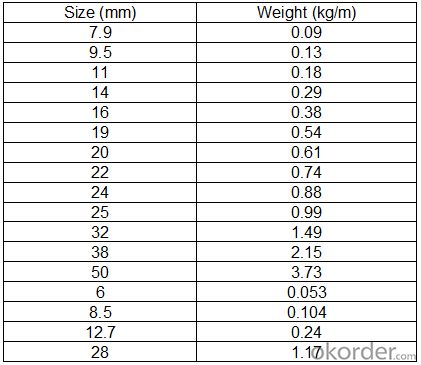

4. FRP Rod Specification

5. FAQ of FRP Rod

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: The difference between FRP process tubes and GRP tubes

- Kashi Eisa's goal is to increase stiffness (large pipe defects) and reduce costs, and process tubes (mostly small tubes), these two aspects are no problems;

- Q: Glass fiber reinforced plastic pipe to withstand 1.0MPa pressure, pipe wall to do how much thickness?

- This depends on the size of the pipe diameter, the greater the diameter, the thicker the wall.

- Q: FRP acceptance standard

- Perform hydrostatic test. In order to comprehensively check the installation quality of pipes, the pressure test shall be carried out according to the test methods stipulated in the code for construction and acceptance of water supply and drainage pipe works, and the allowable seepage water quantity shall be carried out according to the standards of the steel pipe.

- Q: FRP pipe and 0.7 thick galvanized pipe which cost is low?

- Glass steel pipeline, FRP pipe and 0.7 galvanized steel pipe glass steel pipes cost is obviously low, FRP pipe material factory manufacturing costs and labor costs are relatively low, the price is only about the same thickness of galvanized pipe 60-70%, I hope you can help!

- Q: The difference between GRP cable duct and PVC cable pipe

- PVC cable pipe refers to various kinds of rigid PVC pipes made of PVC resin as main raw material and various stabilizers.

- Q: Where are the advantages of FRP pipes? Long life?

- AntifoulingThe pipe surface using unsaturated polyester resin, so the surface is clean and smooth, not by sea or sewage in a shell, fungi and other microbial contamination of borers, so increasing roughness, reduce cross section, increase maintenance costs. No such pollution, long-term use clean as before.

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- PE bellows is good, and now they are so connected.

- Q: Why more and more people choose FRP pipe?

- The cost performance of FRP pipes is higher than that of PP, PVC, PE or concrete, and the strength, hardness and toughness of PP, PE and PVC are not as good as those of FRP pipes

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- 3PE has some disadvantages. (1) the bending of the guiding hole and the protruding rock, pebble and gravel in the hole will cause friction and scratch to the relatively soft 3PE corrosion resistant layer. (2) 3PE coating using polyethylene heat shrinkable sleeve joint, the convex part of the concave or lap joint, which makes it easy to travel being scratched or pulled off lead. (2) 3PE corrosion protection layer has a strong electrical shielding, so that the cathodic protection current is difficult to reach the defects of corrosion protection layer, thus causing perforation corrosion.So, from the last century at the beginning of 90s, the United States developed Powercrete (s) Powder Concrete Anticorrosion structure, namely in the bottom of fusion bonded epoxy powder, sprayed with epoxy resin as main film-forming material, and adding a two-component epoxy coating for concrete, polymer concrete curing agent and other inorganic fillers. The coating is tough and wearable and can be used directly in FBE coated pipes to protect the pipe from damage during handling, directional drilling, crossing, etc..

- Q: Glass fiber reinforced plastic pipeline to do anti-corrosion?

- Glass fiber reinforced plastic itself belongs to a kind of anticorrosive material, and usually needs no antiseptic treatment. However, mainly depends on the environment and requirements.

Send your message to us

High Strength FRP Rods Fiberglass 10mm Rebar Composite Pipes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords