HD Sublimation Coated Aluminum Metal White Sheets for Railcars

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium Reflective sheet

Allou or No.: Alloy

Alloy No.: AA1050, AA1060, AA1070, AA1070

Temper: H18, H16, H24, H24

Thickness: 0.2-3mm

Width: 10mm-2200mm

Length:10mm-2200mm

Tensile strength: ≥140N/mm2

Elongation: ≥2%(H26)

Yield Strength: ≥120N/mm2

Usage: Lights, grille lamp, tunnel lamp, solar collector etc.

Product Description

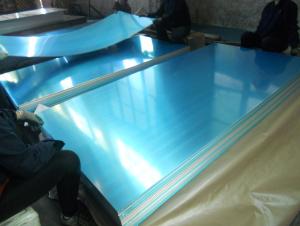

Our aluminum sheets are designed to showcase fine art photo prints with the most brilliant colours, highest dynamic range and best contrasts of all available printing technologies. In contrast to normal direct flatbed printing on composite materials, sublimation aluminum sheets are sublimation boards, the photos are transferred through a printed transfer paper in a heat press.

Feature

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home applications.

7. High quality, factory price.

Process

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top

4. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

5. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

6. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

7. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.25Mpa.

8. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

9. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

10. Enjoy your personal designed aluminum board!

- Q: what are the differences between aluminium , iron , steel.... properties like strength , durability , corrosion resistance properties...finally which is cost efficient and best for all purpose..??

- Duraluminium is cost efficient and best for all purpose.

- Q: How does the surface finish affect the optical properties of aluminum sheet?

- The surface finish of aluminum sheet can greatly impact its optical properties. A smooth surface finish can enhance the reflectivity and brightness of aluminum, making it more reflective and shiny. On the other hand, a rough surface finish can scatter and diffuse light, reducing the reflectivity and making the aluminum appear dull. Therefore, the surface finish plays a crucial role in determining the optical qualities of aluminum sheet.

- Q: This question asks if aluminum sheets can be recycled repeatedly without losing their quality.

- <p>Yes, aluminum sheets can be recycled multiple times without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the material's properties. In fact, recycled aluminum requires significantly less energy to produce compared to mining and refining new aluminum from bauxite ore. This makes aluminum recycling an environmentally friendly and cost-effective process, contributing to sustainability and reducing the demand for raw materials.</p>

- Q: Can 101 aluminum sheets be stamped or engraved?

- Yes, 101 aluminum sheets can be stamped or engraved.

- Q: What are aluminum sheets used for?

- Due to their unique properties and versatility, aluminum sheets find a wide range of uses. In the construction industry, they are commonly employed for roofing, siding, and cladding, thanks to their lightweight nature, corrosion resistance, and durability. These qualities make them ideal for such purposes. In the transportation industry, aluminum sheets are widely utilized in the manufacturing of automobiles, trains, and aircraft due to their high strength-to-weight ratio. They also serve as a lightweight yet sturdy solution for trailers, truck bodies, and shipping containers. Another significant application of aluminum sheets lies in the manufacturing of consumer products. They are used to make household appliances, cookware, and electronics, as they possess excellent thermal conductivity and resistance to rust and corrosion. Additionally, their ability to withstand various weather conditions makes them suitable for the production of signage, billboards, and displays. In the packaging industry, aluminum sheets play a crucial role in the production of cans, foils, and lids. Their impermeability to light, moisture, and oxygen helps preserve the freshness and quality of food and beverages. Moreover, aluminum sheets have various industrial applications. They are utilized in the fabrication of industrial machinery, equipment, and tools due to their excellent machinability and strength. Additionally, their thermal and electrical conductivity makes them suitable for the production of heat exchangers, solar panels, and electrical conductors. In summary, aluminum sheets find application in construction, transportation, consumer products, packaging, and various industrial sectors, owing to their lightweight, corrosion resistance, durability, thermal conductivity, and electrical conductivity.

- Q: How does the thickness tolerance of aluminum sheet affect its usability?

- The thickness tolerance of aluminum sheet plays a significant role in determining its usability. The thickness tolerance refers to the acceptable deviation from the specified thickness of the sheet. It is typically expressed as a range or a plus/minus value. A tighter thickness tolerance ensures that the aluminum sheet meets the desired specifications consistently. This is crucial for applications where precise dimensions are required, such as in aerospace, automotive, and construction industries. In these applications, even a slight deviation in thickness can negatively impact the performance and functionality of the product. For instance, in aircraft manufacturing, the thickness tolerance of aluminum sheets used for structural components is highly critical. A thin sheet might compromise the structural integrity, while a thicker sheet could lead to excess weight, affecting fuel efficiency. Similarly, in the automotive industry, precise thickness tolerance is essential for ensuring compatibility and fitment of various components. On the other hand, a looser thickness tolerance can be acceptable for applications where precise dimensions are not as critical. For example, in general fabrication, signage, or decorative purposes, a wider thickness tolerance may not significantly affect the usability or appearance of the aluminum sheet. Additionally, the cost of manufacturing aluminum sheets with tighter thickness tolerances is typically higher due to increased precision and quality control measures. Therefore, the required level of tolerance should be balanced with the intended use and cost considerations. In conclusion, the thickness tolerance of aluminum sheet directly affects its usability, particularly in industries requiring precise dimensions. It is essential to select the appropriate tolerance level to ensure the sheet meets the required specifications, maintaining the desired performance and functionality of the final product.

- Q: Can the aluminum sheets be used for manufacturing automotive wheels?

- Yes, aluminum sheets can be used for manufacturing automotive wheels. Aluminum is a lightweight and durable material that is commonly used in the automotive industry due to its high strength-to-weight ratio. Aluminum sheets can be formed and machined into the desired shape and specifications required for automotive wheels. Additionally, aluminum has excellent corrosion resistance properties, which is beneficial for automotive wheels that are exposed to various weather conditions and road debris. Overall, aluminum sheets are a suitable material for manufacturing automotive wheels, providing a balance of strength, weight, and corrosion resistance.

- Q: Can aluminum sheets be polished for a mirror-like finish?

- Indeed, a mirror-like finish can be achieved by polishing aluminum sheets. Due to its relatively soft nature, aluminum can be effortlessly polished to a remarkable shine. Typically, the process entails sanding the surface using increasingly finer grades of sandpaper, then buffing with polishing compounds and a gentle cloth or a polishing wheel. The objective is to eliminate any blemishes or marks on the surface, resulting in a sleek and reflective appearance. By employing proper methods and tools, aluminum sheets can be polished to an exquisite shine, rendering them ideal for diverse applications such as decoration, automotive components, or reflective surfaces in optical instruments.

- Q: How does the alloy composition affect the mechanical properties of aluminum sheet?

- The alloy composition of aluminum sheet plays a significant role in determining its mechanical properties. The inclusion of different elements in the alloy can influence its strength, hardness, ductility, and other characteristics. For instance, adding small amounts of copper or manganese can enhance the strength of aluminum, while magnesium can improve its corrosion resistance. Additionally, the size and distribution of alloying elements within the sheet can also impact its mechanical properties. Therefore, careful selection of alloy composition is crucial to achieve the desired mechanical performance of aluminum sheet.

- Q: What's the standard thickness of aluminum sheet?

- the thickness of tobacco aluminum foil and red wine bottle cap is designed according to customers demands and manufacturer has no stated specification.

Send your message to us

HD Sublimation Coated Aluminum Metal White Sheets for Railcars

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords