Sublimation Aluminum Metal Sheets for Continuous Casting Aluminium Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

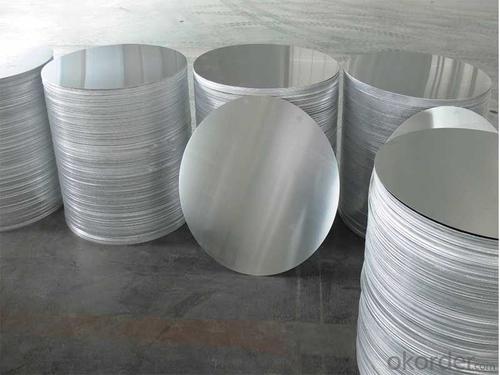

1.Structure of Continuous Casting Aluminium Coil for Circles

Continuous Casting Aluminium Coil for Circles is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Coil for Circles

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1500MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: is general aluminum sheet fire-proof?

- general aluminum sheet is less fireproof than tinfoil.

- Q: Could induction heating fuenace be packaged with aluminum foil as insulation material?

- You have thought about it carefully, you can't use aluminum foil.

- Q: What are the different surface treatments for aluminum sheets to improve corrosion resistance?

- There are several surface treatments available for aluminum sheets that can significantly enhance their corrosion resistance. These treatments include: 1. Anodizing: Anodizing is a widely used surface treatment for aluminum sheets. It involves immersing the aluminum in an electrolyte solution and applying an electric current. This creates a protective oxide layer on the surface of the aluminum, which improves its corrosion resistance. 2. Chromate Conversion Coating: Chromate conversion coating, also known as chemical film or chromating, is another common treatment for aluminum sheets. It involves immersing the aluminum in a solution containing chromate compounds. This forms a thin layer of chromate on the surface, which acts as a barrier against corrosion. 3. Powder Coating: Powder coating is a dry finishing process where a powdered polymer is sprayed onto the aluminum surface and then cured under heat. This creates a durable and corrosion-resistant coating that provides excellent protection against environmental factors. 4. E-coating: Electrophoretic coating, or e-coating, is an immersion-based process in which the aluminum sheet is submerged in an electrically charged paint bath. This attracts the paint particles to the surface, creating a uniform and corrosion-resistant coating. 5. Cladding: Cladding involves bonding a layer of a different metal, such as stainless steel or zinc, to the aluminum sheet's surface. This creates a protective barrier that shields the aluminum from corrosion. 6. Organic Coatings: Applying organic coatings, such as acrylic or polyester paints, to the aluminum surface can provide an effective corrosion-resistant barrier. These coatings form a protective film that prevents moisture and corrosive substances from reaching the aluminum. It is important to note that the choice of surface treatment depends on various factors, including the specific application, environmental conditions, and desired appearance. Some treatments may be more suitable for certain industries or environments, so it is advisable to consult with professionals to determine the most appropriate treatment for a particular application.

- Q: What are the methods used to treat the surface of aluminum sheets to improve their properties or appearance?

- <p>Surface treatment of aluminum sheets involves various processes to enhance their properties or appearance. These include anodizing, which creates a protective oxide layer; painting, which provides a decorative and protective coating; powder coating, a durable and corrosion-resistant method; polishing, which gives a shiny finish; and etching, which creates decorative patterns. Other treatments include chemical conversion coatings, such as chromate and phosphate, for corrosion resistance, and thermal spraying for wear resistance. Each method serves a specific purpose, from improving durability to aesthetic enhancement.</p>

- Q: What is the melting point of 101 aluminum sheets?

- The melting point of 101 aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: What types of bonds can aluminum form: Covalent, Ionic and/or Metallic?Could you post the source, I've been looking for a while now :/

- Well, any metal can have metallic bonds. Aluminum is a metal and is able to alloy with other metals to modify its properties. The criteria for covalent versus ionic are: (see link 1) If the electronegativities are equal (i.e. if the electronegativity difference is 0), the bond is non-polar covalent. If the difference in electronegativities between the two atoms is greater than 0, but less than 2.0, the bond is polar covalent. If the difference in electronegativities between the two atoms is 2.0, or greater, the bond is ionic. All you need to do is determine the difference in electronegativity to see if the bond is polar covalent or ionic for the compounds of aluminum. The official line is that if a metal and a nonmetal react then the bond is ionic. But, it is not quite that simple. We finally have to look at the difference in electronegativity between the element that make up the compound. Examples: Aluminum oxide Al2O3, aluminum chloride AlCl3 (actually this is Al2Cl6), aluminum fluoride AlF3, aluminum carbide Al4C3. Electronegativity (Pauling Scale): 1.61 for Al Electronegativity (Pauling Scale): 3.44 for O Difference = 1.83 Bond is polar covalent Electronegativity (Pauling Scale): 1.61 for Al Electronegativity (Pauling Scale): 3.16 for Cl Difference = 1.55 Bond is polar covalent Electronegativity (Pauling Scale): 1.61 for Al Electronegativity (Pauling Scale): 3.98 for F Difference = 2.37 Bond is ionic Electronegativity (Pauling Scale): 1.61 for Al Electronegativity (Pauling Scale): 2.55 for C Difference = 0.94 Bond is polar covalent This type of analysis can be done for many other actual compounds of aluminum. Try some yourself. Hope this is helpful to you. JIL HIR

- Q: Can the aluminum sheets be used in the construction industry?

- Certainly, the construction industry can make effective use of aluminum sheets. Aluminum proves to be a highly adaptable and lightweight material, offering numerous advantages for construction purposes. Its resistance to corrosion makes it especially suitable for outdoor structures and buildings. Roofing, siding, window frames, doors, and other architectural components often incorporate aluminum sheets. Moreover, aluminum's exceptional strength-to-weight ratio enables the creation of sturdy and efficient structures. Its malleability also facilitates easy fabrication and shaping into various forms, allowing for imaginative and groundbreaking designs in construction projects. Overall, aluminum sheets remain a widely favored choice in the construction industry due to their enduring nature, adaptability, and aesthetic appeal.

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean. Aluminum is a non-porous material, which means that it does not absorb liquids or stains easily. This makes it relatively easy to wipe off dirt, dust, or spills from the surface of aluminum sheets using a damp cloth or sponge. Additionally, aluminum is resistant to rust and corrosion, so it does not require any special cleaning agents or treatments. However, it is important to note that abrasive cleaners or scrubbing pads should be avoided as they can scratch the surface of the aluminum. Overall, with regular maintenance and proper cleaning techniques, aluminum sheets can be kept clean and in good condition for a long time.

- Q: What specific conditions are necessary for the storage and transportation of aluminum sheets to ensure their quality and safety?

- <p>Yes, there are special requirements for storing and transporting aluminum sheets. Aluminum sheets should be stored in a dry, cool place to prevent moisture and temperature extremes which can cause warping or corrosion. They should be stacked flat and evenly to avoid bending or denting. When transporting, aluminum sheets should be secured to prevent shifting during transit, which can lead to damage. Protective coverings may be used to shield the sheets from dirt, scratches, or other potential hazards. It's also crucial to handle the sheets carefully to avoid bending or denting, which can occur if they are not properly supported during transport.</p>

- Q: Are the aluminum sheets recyclable?

- Aluminum sheets possess a high level of recyclability, making them an excellent choice for sustainable practices. This versatile material stands as one of the most recyclable substances on Earth, capable of undergoing an infinite recycling process without compromising its quality. Opting for aluminum sheet recycling proves advantageous as it demands less energy than producing fresh aluminum from raw materials, yielding significant environmental advantages. The recycling procedure involves melting down the sheets to extract the metal, which can subsequently be utilized to create new aluminum products. By recycling aluminum sheets, not only do we conserve precious resources, but we also contribute to the reduction of greenhouse gas emissions and landfill waste. Therefore, it is highly advisable to prioritize the recycling of aluminum sheets whenever possible.

Send your message to us

Sublimation Aluminum Metal Sheets for Continuous Casting Aluminium Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords