Aluminum Sheets Miami - Continuous Casting Aluminium Coils for Re-Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

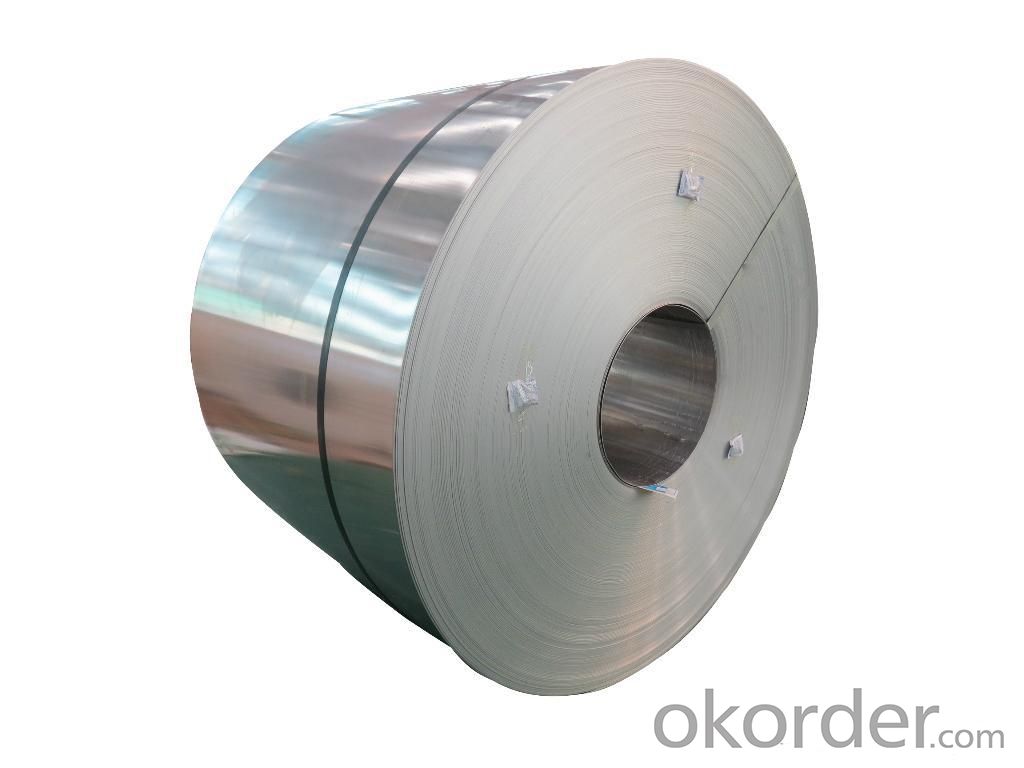

1.Structure of Continuous Casting Aluminium Coils for Re-Casting

Continuous Casting Aluminium Coils for Re-Casting is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Coils for Re-Casting

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | TEMPER | ROLLING | THICKNESS | WIDTH |

| AA1050 | F | CONTINUOUS | 3-8MM | 1000MM-1500MM |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How many molecules are in 1 square foot of aluminum foil?

- Since aluminum foil is an amalgamation of various metals you would first need to know the full chemical breakdown in order to determine how many molecules there are in a square foot of aluminum foil. That said, if your foil was 100% aluminum, you could determine the number of AL atoms by first determining the mass of the foil and dividing by the molecular weight of AL. Multiply that by 6.022 x 10^23 to determine the number of atoms.

- Q: Can aluminum sheets be used in aerospace applications?

- Indeed, aluminum sheets find utility in aerospace applications. The aerospace industry extensively relies on aluminum owing to its remarkable amalgamation of strength, lightweight characteristics, and corrosion resistance. It finds application in diverse aircraft components including the fuselage, wings, and structural panels, wherein reducing weight is paramount for enhancing fuel efficiency and performance. Moreover, aluminum sheets can be conveniently fabricated and molded into intricate forms, rendering them apt for a multitude of manufacturing procedures in the aerospace sector.

- Q: Hi everyone, I have this problem that I'm somewhat confused about. The problem is:An alloy of aluminum and magensium was treated with sodium hydroxide solution, in which only aluminum reacts to give hydrogen gas:2Al + 2NaOH + 6H20 --gt; 2NaAl(OH)4 + 3H2If a sample of alloy weighing 1.118 g gave 0.1068 g of hydrogen, what is the percentage aluminum in the alloy?How do I account for the magnesium and what stoichiometric relationships would I need to set-up? This is very confusing, but I appreciate the slightest of help on this!Thank you.

- You don't need to worry about the magnesium at all, because it doesn't enter into the reaction. You have a balanced equation for aluminium and hydrogen, and the data given are sufficient: From the equation, you know that 2 moles of aluminium produce 3 moles of H2. 0.1068 g of H2 were produced, so divide this by molecular mass of H2 (2.016) to determine the moles of H2 produced. You know that 3 moles of H2 would have been produced from 2 moles of Al. Therefore, multiply the moles of H2 by 2/3, to determine the moles of Al that were present. Now multiply this number by the atomic mass of Al, to determine the grams of Al. Now divide this number if grams by 1.118 and multiply by 100 to determine % Al present in the alloy.

- Q: I'm about to fix the aluminum wiring in my house using Alumiconn connection, so I know that every outlet and switch plate need to be done, do the light fixtures need to be done as well? And also does anything need to be done with the main circuit breaker?

- I never understood why aluminum wire was ever used, it is inherently unsafe. I would replace the whole thing with copper.

- Q: Can aluminum sheets be anodized with custom colors?

- Yes, aluminum sheets can be anodized with custom colors. Anodizing is an electrochemical process that adds a protective oxide layer to the surface of aluminum, enhancing its durability and corrosion resistance. During the anodizing process, the aluminum sheet is immersed in an electrolytic solution and an electrical current is passed through it. This causes a controlled oxidation of the aluminum surface, creating a porous layer that can be dyed to achieve custom colors. By carefully selecting the dye, different shades and hues can be achieved, allowing for a wide range of custom color options. Additionally, anodized aluminum sheets can also be further processed with techniques such as laser engraving or printing to create unique designs and patterns, making them a versatile choice for various applications in industries like architecture, automotive, and electronics.

- Q: What are aluminum sheets?

- Aluminum sheets, commonly found in various industries and applications, are thin and flat pieces of aluminum. Aluminum, a lightweight and versatile metal, is known for its exceptional strength, durability, and corrosion resistance, from which these sheets are made. Depending on the project's specific requirements, the thickness, width, and length of these sheets can vary. Construction, automotive, aerospace, packaging, and manufacturing industries, among others, widely employ aluminum sheets. They serve various purposes, including roofing, cladding, signage, transportation, electrical enclosures, and even household utensils. Aluminum's flexibility and malleability make it a popular choice for a wide range of applications, as it can be easily shaped and formed. Furthermore, aluminum sheets can be coated or finished, enhancing their appearance and protecting them from external factors like moisture, UV rays, or chemicals. In summary, aluminum sheets are indispensable materials that offer a combination of lightweight, strength, and corrosion resistance, making them ideal for industrial and commercial uses.

- Q: Are aluminum sheets suitable for signage applications?

- Indeed, signage applications can benefit from the use of aluminum sheets. Due to its lightweight nature and durability, aluminum proves to be an ideal material for outdoor signs that must endure diverse weather conditions. Its resistance to rust and corrosion guarantees the sign's longevity. Moreover, aluminum sheets can be effortlessly customized and shaped into various sizes, enabling the creation of versatile and imaginative signage options. Furthermore, aluminum serves as an exceptional material for digital printing, producing top-notch graphics and images. All in all, aluminum sheets present remarkable durability, versatility, and aesthetic allure, cementing their status as a favored choice for signage applications.

- Q: Can aluminum sheets be used in automotive applications?

- Yes, aluminum sheets can be used in automotive applications. Aluminum is lightweight, corrosion-resistant, and has good strength-to-weight ratio, making it an ideal material for manufacturing automotive components such as body panels, engine parts, and structural components.

- Q: Do 101 aluminum sheets require any special maintenance or care?

- 101 aluminum sheets do not require any special maintenance or care. Aluminum is a durable and corrosion-resistant material, so it can withstand various environmental conditions without deteriorating. However, to ensure their longevity and optimal performance, it is recommended to keep them clean from dirt or debris by regularly wiping them with a soft cloth or sponge. Additionally, avoiding abrasive or harsh cleaning agents is advisable to prevent any potential damage to the aluminum sheets. Overall, with minimal attention and care, 101 aluminum sheets can maintain their quality and appearance for an extended period.

- Q: Are aluminum sheets suitable for aircraft panels?

- Yes, aluminum sheets are suitable for aircraft panels. Aluminum is widely used in the aviation industry due to its excellent strength-to-weight ratio, which makes it ideal for constructing lightweight yet strong aircraft structures. Aluminum sheets are commonly used for aircraft panels because they offer a combination of durability, corrosion resistance, and ease of fabrication. Additionally, aluminum can be easily formed and welded, allowing for complex panel shapes to be created. Furthermore, aluminum has good electrical conductivity, which is important for the proper functioning of various aircraft systems. Overall, the use of aluminum sheets for aircraft panels helps to ensure the structural integrity and performance of the aircraft.

Send your message to us

Aluminum Sheets Miami - Continuous Casting Aluminium Coils for Re-Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords