Graphite electrode uhp 600 for EAF in steel industry and stainless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin:

Hebei, China

Brand Name:

JINSH

Model Number:

UHP 600mm

Type:

Electrode Bolt

Application:

eaf

Length:

1600-2700

Grade:

UHP (Ultra High Power)

Resistance (μΩ.m):

5.5Ω

Apparent Density (g/cm³ ):

1.68

Thermal Expansion:

1.5

Flexural Strength (N/㎡):

11Mpa

Packaging & Delivery

Packaging Details

Wooden box and tray packaging, should be fixed by steel belt

Port: TIANJIN

Lead Time :

Quantity(Tons) 1 - 100 101 - 500 501 - 2000 >2000 Est. Time(days) 7 15 15 To be negotiated

Product discription

| Graphite electrode uhp 600 for EAF | |

Resistance | 5.5 |

| μ Ω.m(Max) | |

Density | 1.68 |

| g/cm³(min) | |

Flexure Strength | 11 |

Young's Modulus | 14 |

| Gpa(Max) | |

Ash Content | 0.2 |

| %(Max) | |

CTE(100-600℃) | 1.5 |

| 100-6/℃(Max) | |

Application

Graphite electrodes are widely used for production of alloy steels, metal and other nonmetallic materials, etc.

* DC electric arc furnace.

* AC electric arc furnace.

* Submerged arc furnace.

* Ladle furnace.

Size information

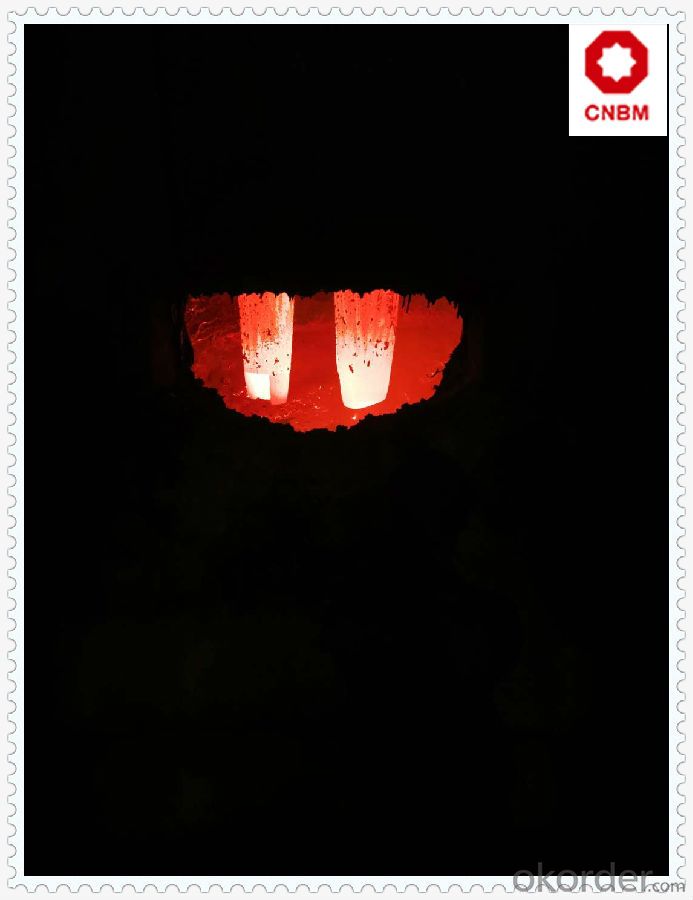

Detailed Images

- Q: Why is graphite conductive electrode oxidized?

- Graphite electrode uses petroleum coke (carbon), pitch coke (carbon) as granule material

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- When the tool is broken, it will not only stop the continuous processing of the steel, but also affect the quality of the product, which will lead to the scrap of the parts and the waste of the material. Considering the foreseeable future, the graphite electrode will occupy a high position, usually used equipment for processing graphite electrode the highest efficiency mold manufacturers will unremittingly, expand and between those determined to use the hard steel processing manufacturer competition gap. The foundation of micro cutting tools, in terms of graphite electrodes, is one of its most magical words: "high speed."". The spindle speed of the high speed machining center is up to 30000~60000r/min, and the feed speed can be increased to shorten the processing period and improve the quality of the surface and edge. The motor needed to drive this type of spindle is relatively small and light, which helps to reduce cutting power and reduce tool breakage. This is critical because many of the electrodes are complex, and their production involves small, easily broken micro tools (see Figure 1).

- Q: Graphite electrode in milling machine processing, dust is especially big, boot 5 minutes, workshop can not open the figure, what is the solution?

- Because will cause a short circuit, the best selection of bag type dust collector, our company is graphite in Linzhou, and before you like, then Xinxiang Keli machinery to help us to design a set of dust removal equipment, and then the operation almost no dust, you can consult the specific

- Q: Synthesis techniques of carbon nanotubes

- Catalytic pyrolysis is one of the widely used methods for preparing carbon nanotubes. The method mainly uses transition metal as catalyst, and is suitable for large-scale preparation of carbon nanotubes. The content of carbon nanotubes in the products is higher, but the defects of carbon nanotubes are more.

- Q: The difference between graphite electrode and graphite rod

- Graphite rod for non metal products, as carbon arc gouging cutting process in an essential pre welding cutting supplies, is composed of carbon and graphite with appropriate adhesive, through the extrusion, the temperature of 2200 DEG C after baking rotary plating a layer made from copper, high temperature resistance, good electrical conductivity, is not easy fracture, suitable for metal cutting into required shape.

- Q: Graphite electrode press device

- (1) ordinary power graphite electrode, using graphite electrode with current density lower than 17A / cm 2, is mainly used in steel-making, smelting silicon, refining yellow phosphorus and other common power electric stove(2) anti oxidation coating graphite electrode. The surface is coated with an anti oxidation protective layer of graphite electrode to form a protective layer which has both conductive and high-temperature oxidation resistance, thus reducing the electrode consumption during steelmaking

- Q: What are the factors that affect the electrode wear rate of machine tools?

- Effect of processing voltage on electrode wear. The processing voltage is the average voltage between the discharge time and the gap. When the voltage is lower than the power supply voltage (voltage) 25%, electrode loss will increase, which is due to the electrode and the workpiece is too close, the discharge column energy is too large, the electrodes generate heat radiation is too strong, at the same time, there are a large number of continuous arc discharge. But the working voltage is too high (partial load processing), bad conditions of thermal effect in the gap, is not conducive to the adsorption of copper electrode of carbon graphite, destroy the covering effect. Similarly, the electrode loss increase, therefore, corresponding to different processing standards should be selected to adjust the discharging gap voltage.

- Q: Jiqiu conductive graphite electrode, how to compare with copper is relatively large resistance value?

- This is not a good estimate of the sheet graphite resistance after 5mm

- Q: What is the composition of petroleum coke and what is its use?

- Mainly used for making carbon products, such as graphite electrodes, anode arc, steel, non-ferrous metals, with aluminum for use; silicon carbide products, such as grinding wheel, rubber, sandpaper; producing goods for the production of synthetic fiber, calcium carbide acetylene and other products; also can be used as fuel for fuel, but for grading impact for grinding superfine grinding, through the JZC-1250 device can be made of coke powder after combustion, using coke powder as fuel is mainly some glass factory, coal water slurry plant etc..

- Q: Graphite is made of high-strength graphite, it is a kind of graphite grade specification.

- Most of the graphite electrodes are cylindrical, but also have square and multi ribbed shapes. Graphite blank refers to the firing of raw materials without processing graphite.

Send your message to us

Graphite electrode uhp 600 for EAF in steel industry and stainless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches