700mm HP Grade Graphite Electrode for EAF Foundry Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

Topfly Material has complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line.

Graphite electrodes, widely used in steelmaking, non ferrous, silicon industry. According to their level of quality, it can be divided into RP, HP and UHP grade. This item is for UHP grade graphite electrode. Resistivity: ≤6.5ohm, Bulk Density: ≥1.65g/cm3. Diameter is 300-600mm, length is 1800±100mm.

2.Main Features of the Graphite Electrode

(1) High quality and carbon content, widely used in the foundry market

(2) Competitive price, we have price advantage for UHP.

(3) High density ≥1.65g/cm3 and low resistivity≤6.5ohm

(4) Large quantity in stock, you can order directly.

3.Graphite Electrode Images

More products for your reference:

Packaging: Wooden Pallets

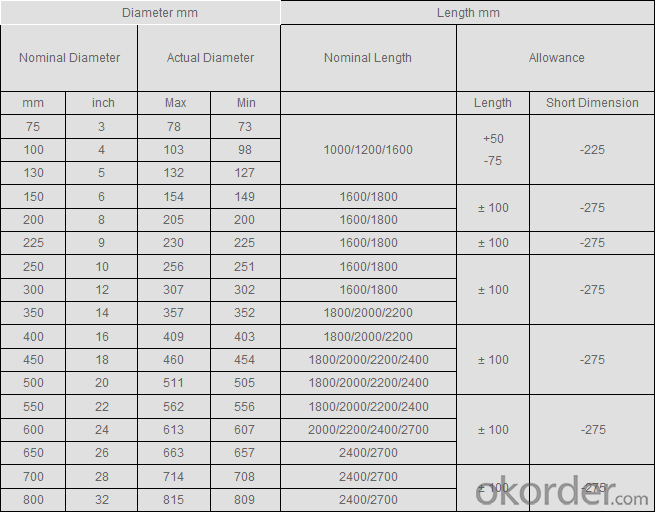

4.Graphite Electrode Specification

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(2) MOQ

For trial order, we accept 20 MT.

(3) Payment term

30% deposit, balance against the BL copy; 100% L/C at sight.

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit or L/C.

- Q: Is graphite electrode good for foreign trade?

- Profits can be made for foreign trade. Even if you produce it yourself. Traders take big head. Own production. It's hard for you to play. If you have a client, we can work together

- Q: What is the graphite furnace electrode with a diameter of 400?

- With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: Will the brush grease not short-circuit the commutator?

- The reverse pole surface should be clean and dry. Any grease, moisture or dust will destroy the carbon film on the commutator surface. The carbon film can not be formed or destroyed. It is very harmful. Grease material will be embedded in the joint between commutator and commutator. Under the action of electric spark, it will be carbonized and conductive. When serious, it will cause partial short circuit between the reversing pieces and reduce the service life of reversing.

- Q: What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The graphite part is called pyrolytic graphite. Stronger than ordinary graphite, strong oxidation resistance.

- Q: Is the anode of electrolytic water suitable for ordinary titanium wires?

- Graphite firstFirst of all, the titanium electrode is usually not pure titanium, it should be titanium with a metal oxide coating. Secondly, the advantages of the titanium electrode is mainly to save electricity, the corrosion resistance of carbon is much stronger than that of industrial production, if the meaning is relatively large, but it is still in laboratory experiments, electrolysis of water, not what meaning.

- Q: Graphite can be used in acid towers in chemical plants because of graphite

- Ultra high power graphite electrode. A graphite electrode that allows current densities greater than 25A/ cm 2 is allowed. Mainly used in ultra high power steelmaking arc furnace

- Q: National standard for graphite electrodes

- Page 7 the international standard specifies the shape, dimensions and tolerances, technical requirements, test methods, packaging, marking, storage, transportation and quality certificates of graphite electrodes. This standard applies to high quality petroleum coke, asphalt, coke as the main raw material, through molding, roasting, impregnation, graphitization and mechanical processing made of, power supply arc furnace as conductive material of ordinary power graphite electrode. Common power graphite electrode GB

- Q: How much does a graphite electrode cost about a ton?

- According to purity and quality, the price is 1-6 tons / tonDo not calculate the processing cost

- Q: How can the graphite powder be processed into high quality carburizing agent? Thank you

- So that impurities on the high, so basically can not be processed into so-called quality, and can leave a contact, discuss each other

- Q: What is the composition of petroleum coke and what is its use?

- Mainly used for making carbon products, such as graphite electrodes, anode arc, steel, non-ferrous metals, with aluminum for use; silicon carbide products, such as grinding wheel, rubber, sandpaper; producing goods for the production of synthetic fiber, calcium carbide acetylene and other products; also can be used as fuel for fuel, but for grading impact for grinding superfine grinding, through the JZC-1250 device can be made of coke powder after combustion, using coke powder as fuel is mainly some glass factory, coal water slurry plant etc..

Send your message to us

700mm HP Grade Graphite Electrode for EAF Foundry Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords