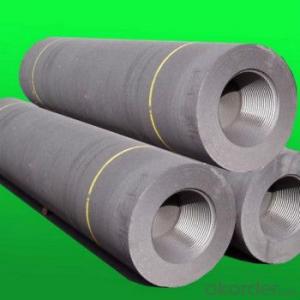

Graphite Electrode Manufacturer's Hot Sale UHP 600mm Graphite Electrode for Steeling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

China Manufactured Graphite Electrode

Graphite electrode is made from the domestic petroleum coke as well as high quality needle coke which are widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials

Other related properties include: Graphite / Steel Welding Electrode

Graphite / Steel welding electrode belongs to carbon steel electrode, which is commonly used for automobile bodies, ornamental iron, metal furniture, truck frames and bodies, farm implementations, machinery guards and storage tanks.

Main Product Features:

· Stable arc

· More resistant to splatter and smoke inhalation.

· Higher deposition efficiency

· Excellent welding performance

· Easy restrike.

Our welding electrodes have more resistance to splash and smoke, easy restart weld quality design also including resistances to dust and smoke.

Applications

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

Programmable properties

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, HP, UHP

- Q: What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The high purity graphite component is put into the furnace, and nitrogen and methane are produced under vacuum high temperature. Then graphite is shown to produce 10% coating.

- Q: Graphite can be used in acid towers in chemical plants because of graphite

- A graphite electrode coated with an antioxidant protective layer (graphite electrode, antioxidant). The utility model has the advantages of forming a protective layer capable of conducting electricity and resisting oxidation at high temperature, reducing electrode consumption (19%~50%) during steelmaking, prolonging the service life of electrodes (22%~60%), and reducing the electric energy consumption of electrodes.

- Q: Can Naiduo high temperature graphite

- Graphite gasket medium: hot water, steam, oil, acid, alkali, ammonia, hydrogen, organic solvents, hydrocarbons, cryogenic liquids, etc..Maximum use pressure of graphite gasket: 30MPa.Service temperature of graphite gasket: -200~650

- Q: The graphite electrode made by the machining center adopts cooling method, which is water cooled, oil cooled and blow cold. Which is good?

- Use oil cold. Air cooling will cause graphite dust flying, on the one hand, toxic, on the one hand there are security risks (caused by circuit short circuit). Water cooling is virtually out of use, taking into account the maintenance and maintenance of the CNC.

- Q: Do electroplating experiments, graphite as an electrode, graphite how to pre process to ensure that the coating will not fall, resulting in increased color of the solution

- This graphite will eventually wear out, even if you use the nickel plate directly, the nickel plate is still wearing, but compared to graphite than the much better. You should ask the question, the brush plating industry association, oh, they study this stuff all day long.

- Q: Graphite electrode press device

- High power graphite electrodes. Graphite electrodes with a current density of 18 ~ 25A / cm 2 are allowed. They are mainly used in high power arc furnaces for steelmaking

- Q: Why is graphite a negative pole and copper is an anode?

- Graphite, as an electrode material, can conduct electricity, which belongs to an inert electrode. It only acts as a conductive agent, but does not participate in the electrolytic reaction process. So the anode is made, and copper is oxidized in the electrolysis of monovalent cations, so copper is used as the anode.

- Q: Graphitized coke, graphite, broken, mixed up, how to export?

- Graphite fossil oil coke is the best smelting carburizing agent. In the steel-making industry, to produce good steel, there must be good raw materials, including good carburizing agent, and the graphitization of petroleum coke is the best carburizing agent.

- Q: What is anodized graphite?

- According to the production method of brush, there are two kinds. One is colored brush, that is, metal graphite brush. One is black brush. The black brush is made of petroleum coke, pitch coke, carbon black, charcoal and natural graphite powder and so on. Some binders (such as coal tar pitch, coal tar and artificial resin etc.) are added to the black brush. The resin binder by curing brush manufactured for high resistance brush, and the calcined product called carbon brush and graphite brush (with natural graphite as the main raw material) graphitised after product called electrographite brush,

- Q: What are pyrolytic graphite electrodes used for?

- The weight is lighter: the density of graphite is only 1/5 of copper. When the large electrode is used for EDM, it can effectively reduce the burden of machine tools (EDM). It is more suitable for applications on large moulds.

Send your message to us

Graphite Electrode Manufacturer's Hot Sale UHP 600mm Graphite Electrode for Steeling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches