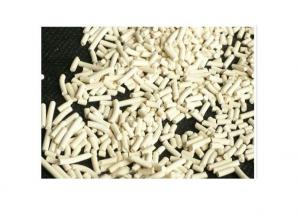

Grade 42.5 R/N P.O CMENT

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

I. CEMENT STANDARD

1.Vietnam standard (TCVN)

- Quality of Cement as per TCVN 6260 - 2009

2.European standard (EN)

- Certificate I -EN 197-1.2000- CEM II 42,5 R

- Certificate II - En 197-1.2000 CEM II 42,5N

- Certificate III - EN 197-1.2000 CEM I 42,5R

3.American standard (ASTM)

- ASTM C150 TYPE-1

- ASTM C1157 TYPE- GU

- ASTM C1157 TYPE- HE

II. SPECIFICATIONS FOR ORIDINARY PORTLAND CEMENT AS PER EN 197-1:2000/CEM II 42.5

Items | Units | Specification | Test Results | Test Method |

SiO2 | % | ≤ 26.00 | 23.41 | EN 196-2 |

Al2O3 | % | ≤ 6.50 | 5.50 | |

Fe2O3 | % | ≤ 4.50 | 3.60 | |

CaO | % | ≥ 54.00 | 57.00 | |

MgO | % | ≤ 5.00 | 2.75 | |

SO3 | % | ≤ 3.5 | 2.56 | |

Loss on Ignition, (LOI) | % | ≤ 10.00 | 7.00 | |

Insoluble Residue | % | ≤ 12 | 6.00 | |

Physical and Mechanical Properties | ||||

Finess test |

|

|

| EN 196-6 |

- Blaine | cm2/g | ≥ 3200 | 3800 | |

- Retained content on sieve 75mm | % | < 15.0 | 0.10 | |

Time of setting - Initial set - Final set | Minutes |

≥ 75 < 420 |

145 200 | EN 196-3 |

Soundness (LeChatelier) | mm | < 10.0 | 1.0 | EN 196-3 |

Compressive strength | MPa |

|

| EN 196-1 |

2 Days | ≥ 20.0 | 23.0 | ||

3 Days | - | 27.0 | ||

7 Days | - | 37.0 | ||

28 Days | ≥ 42.5 | 50.0 | ||

- Q: You are making 10 tons of concrete that is 47.6% cement by mixing a 20% cement mixture with an 89% cement mixture.a) How much of the 89% cement mixture must you use?b) How much of the 20% cement mixture must you use?Answer in units of tons

- a) Let the amount of 89% cement mixture used be X tons Then the amount of 20% cement mixture used will be ( 10 - X) tons 0.89X + 0.20 ( 10 - X) = 10* 0.476 0.89X + 2 - 0.20X = 4.76 0.69X = 2.76 X = 2.76 / 0.69 = 4 ANSWER 4 tons of 89% mixture and 6 tons of 20% mixture

- Q: I live in an older house that has cement floors and they sweat bad .Is there anything I can do to make them stop sweating?

- There a difference between hydrostatic pressure and moisture in the air causing the dampness. Hydrostatic pressure comes from below ( as Don said) and of course the other is in the air, which can be removed w/ a dehumidifier. The other , I haven t heard of anything that will really stop this. Other than basic landscaping to shed water away and to have your cement floor perimeter cut open and drainage tile installed. To find out which one is your problem, dry off an area of the cement w/ a fan and tape( duct tape) a 1ft x1ft pc of foil on to the cement . Leave for 24 hrs, and if you have a lot of moisture after that, chances are your getting water from under the slab. No flooring , other than ceramic flooring, should ever be put on this type of cement w/ this problem. You ll waste your money. GL

- Q: It's for my Science hw....

- As someone who manages hazardous waste shipments. It is not considered flammable, or explosive. It I considered poisonous Because it contains silica

- Q: Question such as the title, the building which area also used in which aspects of the material? Questions added: What should I pay attention to buying these materials? How can we make money in it? More

- Gravel, cement, bricks are generally local materials, referred to as the floor, only according to the local market price, the main impact is freight. Steel is now a lot of suppliers, the price volatility is very large, unstable, only 禒 Fan exercises both Ge Huan fork only Lek Leang at any time inquiry! Make money is basically: low buy high throw! If there is a special relationship, do the middle of the most successful business?

- Q: Has a body ever been found with cement shoes?

- The shoes themselves aren't cement. It's a coined phrase that means to put the victim's feet in a container(s) of cement and let it dry and harden. I've never heard of a case where they found this, but you sure hear a lot of this on tv...especially old-time crime dramas.

- Q: I need a list of cement, concrete and aggregates Public companies the most important ones or largest Co.!

- So. Ca. Riverside Cement on Cedar in Bloomington Also in Oro Grande California on D st California Portland Cement in Colton The biggest cement company is Cal Mat on Riverside Ave in Fontana Ca. They have plants all over the country I use to haul bulk for these companies. Hope this helps.

- Q: I am about to move into a new office and it is all carpet...We are a creative agency and really want that cool loft feel- Anyone know the best way to remove all the carpet ( and the glue ) from the cement and then the best way to stain it to look cool? :) We don't have a huge budget and really hope to be able to do this on our own.Thanks for any help!

- yes isure and want

- Q: Could you make Portland cement with one component only, excluding the gypsum?

- Yes. I worked before in a cement plant (at Tinaan, Naga, Cebu, Philippines). I was a shift control chemist and we fed only one component to the raw grinding process which we deposited to the slurry basin and subsequently mixed it homogeneously at the right proportions before burning in the rotary kiln to produce the clinker. Then in the finish grinding operation, we added the gypsum to control the setting time of the finished product, the cement, at approximately the proportion of 97% clinker and 3% gypsum to produce Type 1 Portland Cement. We were blessed with a very good limestone quarry that approximated almost 75% of Calcium Carbonate to crush and grind and burn to clinker and then grind it to produce cement. So almost everyday, we had only a single component to produce the cement. However, we also had in our feeders aside from the limestone, the marl feeder, the silica feeder and the pyrite cinder feeder to fine tune the raw mix, and especially when we are to produce another type of cement. A good day to you.

- Q: The Now building materials business to do it, including what aspects?

- To see what side, if it is a real estate developed areas, it is very good to do

- Q: this company is sale cemented carbide ,it seems ok ,but I want to know more information about this company .

- I am working in Zhuzhou Jingzuan! i know exactly what they are. they are a new Chinese Company, set up at 2009. before 2009, they are known as Zhuzhou Jingcheng. they are dealing with cemented carbide products: CNC inserts, mining tips, end mill, carbide rods, and tungsten bar,tungsten board. and from 2009 to 2012, they are only sale within China, after May 2012, they begin open their international markets. and what kinds of info do you want to know? you can write to me

Send your message to us

Grade 42.5 R/N P.O CMENT

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords