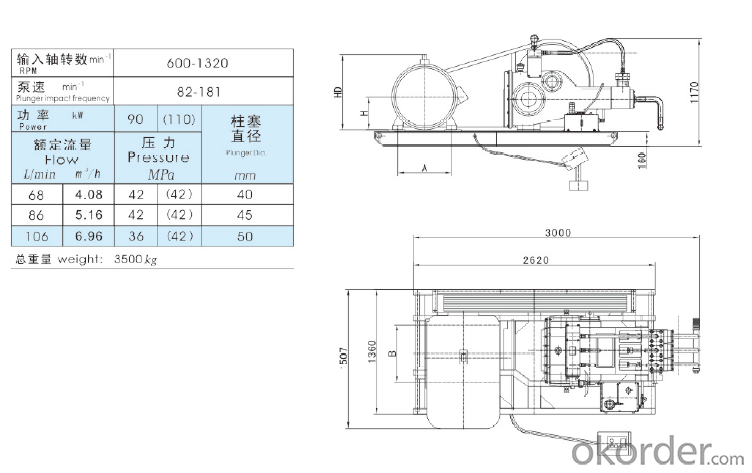

GPB-90WDF Type Slurry Injection High Pressure Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The high pressure triplex pump GPB-90 is widely used now as a power equipment for slurry injection.

◆The special bush structure between crank shaft and connecting rod at power frame

high strength ,strong wear ability ,good lubrication ,small friction coefficient , stable driving at the power end ,lower temperature ,suitable for continuous duty ,operation simple, safely and realiable making the disassembly easier ,saving time and effort

◆It can be used in following fields, the reinforcement in new building, high expressway ,railway, subway and the like, the treatment for old building sedimentation, the construction of waterproof wall for reservoir, dam and engineering, the construction of breast wall, leakage blocking in mine and the wall protection of well ,coal excavation with high pressure jetting, hydraulic liquid supply in well, the large underground pipes cleaning, chemical industry ,stiletto with high pressure water ,other fields as well

◆Technology parameters

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: Can I charge the battery (1.2Vx2) with the suction tube submerged in the water or do I have to remove the suction tube every time I have to charge the battery?

- Since you don't mention the model of the pump, if you can connect the charger with a dry connection, you should not have to remove the pump/tube. If you have to take the battery out, you stand the risk of dropping it in the water putting it back, but obviously (I think) you don't have to remove the pump/tube.

- Q: Where can I get a water pump housing for a 1987 Dodge Dakota, A junk yard?

- Dealership

- Q: Can I get a time estimate to replace a water pump on a 1983 Nissan Sentra? I'm trying to calculate the cost of the repair separate from the part. Thanks.Also, time to replace a battery and the end on one of the attachments to the post.

- couple of hour for a pro and double that for a amature :)

- Q: 1.where is it located and what would I have to remove 1st to get to it. And would I need a torque wrench if so what # would it have to be at when re-installing water pump

- 1990 Toyota Celica

- Q: someone told me my water pump may be going out and it sounds like their is a loose barron inside of it, so how much is it and and if i was to have someone else to fix it how much will it cost me

- type okorder type in your info and look for a how to tyhey have many there an dother guy layed it out pretty well

- Q: can a water pump pumping out air instead of water?

- It depends on the type of pump.Some pumps can others will burn out. Carpet cleaner type suction will happily cope with both air and water,old fashioned hand operated lift pumps do as well. Bilge pumps etc do not like running dry and will have to be reprimed to suck water if the get an air lock.

- Q: Submersible pump and self-priming pump which is easy to use?

- Pump generally installed at less than 7 meters from the water surface, if not meet this requirement, have to use submersible pumps, such as deep wells. Submersible pump is obviously not good, easy to malfunction, have to use.Self-priming pump is mainly convenient, but the performance is lower than the general centrifugal pump.There are both advantages and disadvantages at the same time, which is not easy to use.The key is where to use and how many parameters............

- Q: I have a 1978 El Camino V8 305. My power steering has been going out on me, and since then my belt has been squeaking usually when it first starts up. This morning when I got to work, smoke was bellowing from under my hood. Im trying to troubleshoot. Is it possible that my power steering pump damaged the belt enough that the water pump went out?

- The only method of positive identification is to use a mechanics stethoscope. A failing bearing is most likely causing the whine, but wear in the p/s pump can also create a whining noise which will get noticeably louder when the wheel is turned and held against the stop with the engine running.

- Q: How do you check water pump on 98 deville haveing overhea?

- Not quite sure what you mean, but: Is the water pump malfunctioning? The car is overheating? Well, if it is the water pump, you would need to remove it to check how well it is functioning.

- Q: I'm looking to build a fountain to dispense Wine. For which, I'll need a pump. I'm thinking submersible aquarium pump. I'm concerned about after tastes, and general safety of this venture. Can you drink water that's been run through an aquarium pump?Would alcohol be any different?Is there a better choice? What would it be?

- It wouldn't be a good idea to use a water feature pump or aquarium pump due to the lubrication on the Impeller which can contaminate the wine and make it taste weird. Ofc, if you're going to use enough wine then a small water feature pump will work without changing the taste, either way it is safe enough to drink. Your best bet though would be (something like) a chocolate fountain, but without the heater. Edit: as strange as this may sound, another idea is to use an air pump with an air stone inside a peice of tubing. This is commonly known as a sponge filter, where the uplift from the air rising pushes the liquid up.

Send your message to us

GPB-90WDF Type Slurry Injection High Pressure Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords