Gold Adhesive ASTM B-209 Standards 3000 Series Smooth/Corrugated/Stucco Embossed Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

We are able to supply 1,2,3,5,6,8 series alloy coil, foil and sheets, including 1***, 3***, 3104, 5052, 5182, 5754, 5083,5086,8011,8079

Our products include:

1). Mill-finished aluminum coil:

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011 ,8079etc.

Temper: H14/16/18/22/24/32, HO etc.

Thickness: 0.08mm—100mm

Width: 100mm—2200mm (Can be slitted)

Notice: Embossment can be done if required.

2). Color-Coated Aluminum Coil:

Alloy : AA1050/1100/3003/3005/3105/5005/5052/8079 etc.

Thickness: 0.03mm—1.50mm

Width: 10mm—1600mm (Can be slitted)

Coating : PVDF, PE

Coating thickness: Usually 16-25 micron, could be33-40 micron

Color : According to customers’ requirements

Notice : Embossment can be done if required

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

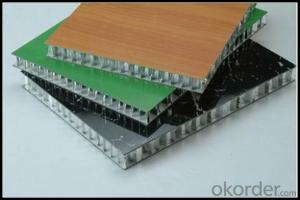

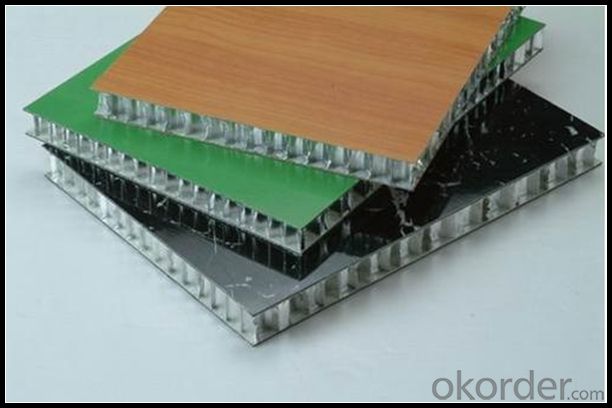

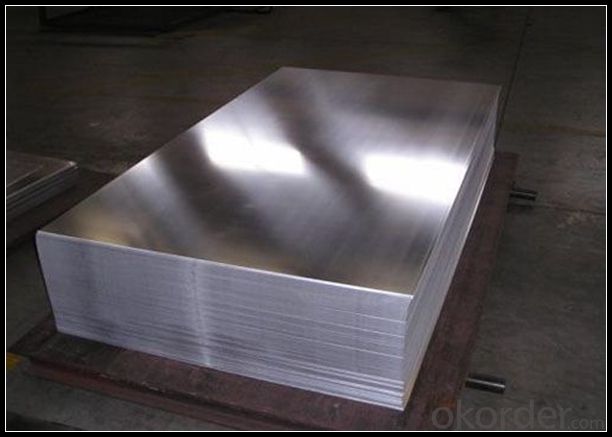

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc |

- Q: what are the differences between aluminium , iron , steel.... properties like strength , durability , corrosion resistance properties...finally which is cost efficient and best for all purpose..??

- Brass is an alloy made of copper and zinc, and will show shades of yellow in it. Musical instruments are made from this as well as ornaments, military buttons etc. Bronze is made from copper and tin, and will appear browner in content. This allow is stronger than brass, and can be used for weapons, long lasting household items, etc.

- Q: What are the different methods of finishing aluminum sheet edges?

- There are several methods for finishing aluminum sheet edges, including filing, sanding, deburring, chamfering, and using edge trim or molding.

- Q: Are aluminum sheets suitable for harsh weather conditions?

- Yes, aluminum sheets are highly suitable for harsh weather conditions. Aluminum is known for its exceptional corrosion resistance, making it highly durable and able to withstand extreme weather conditions such as heavy rains, snow, and strong winds. Additionally, aluminum sheets are lightweight yet robust, which allows them to resist damage from impacts or hailstorms. These properties make aluminum sheets a popular choice for outdoor applications, including roofing, cladding, and siding, as they provide long-lasting protection even in challenging weather environments.

- Q: How is an aluminum sheet manufactured?

- The process called rolling is used to manufacture an aluminum sheet. Initially, a large aluminum ingot is heated to a specific temperature in a furnace. Once the ingot reaches the desired temperature, it is transferred to a rolling mill. Within the rolling mill, the heated aluminum ingot is passed between a series of rolling stands. These stands consist of two steel rollers that apply pressure on the aluminum, steadily decreasing its thickness. As the ingot moves through each stand, the distance between the rollers is altered to achieve the desired thickness. Throughout the rolling process, the aluminum sheet is continuously cooled using water to prevent overheating. This cooling process also enhances the strength and hardness of the sheet. The specific cooling method may vary depending on the alloy and desired properties of the sheet. Once the desired thickness is achieved, the aluminum sheet undergoes further processing to improve its surface finish. This may involve techniques like annealing, where the sheet is heated and gradually cooled to relieve internal stresses and enhance workability. Finally, the aluminum sheet is cut into the desired sizes and shapes using shearing or sawing techniques. It can also undergo additional treatments such as coating, painting, or polishing, depending on its intended application. In summary, the manufacturing of an aluminum sheet involves heating the ingot, rolling it between sets of steel rollers to reduce its thickness, cooling it, and then further processing to achieve the desired surface finish and size. This process guarantees the production of top-quality aluminum sheets suitable for various industries, including construction, automotive, aerospace, and more.

- Q: I can't seem to find what uses or contains Aluminum Nitride. Help!

- Don't know where you looked, but this came up with very basic web search. Metallization methods are available to allow Aluminium nitride to be used in electronics applications similar to those of alumina and beryllium oxide. Among the applications of Aluminium nitride are opto-electronics, dielectric layers in optical storage media, electronic substrates, chip carriers where high thermal conductivity is essential, military applications, as a crucible to grow crystals of gallium arsenide, steel and semiconductor manufacturing. Epitaxially grown thin film crystalline aluminium nitride is also used for surface acoustic wave sensors (SAW's) deposited on silicon wafers because of the Aluminium nitride's piezoelectric properties. One application is an RF filter used in mobile phones called a thin film bulk acoustic resonator (FBAR). This is a MEMS device that uses aluminium nitride sandwiched between two metal layers.

- Q: What are the common surface finishes for aluminum sheets?

- The common surface finishes for aluminum sheets include mill finish, brushed finish, anodized finish, and powder-coated finish.

- Q: Are the aluminum sheets suitable for manufacturing chemical storage cabinets?

- Yes, aluminum sheets are suitable for manufacturing chemical storage cabinets. Aluminum is a strong and durable material that is resistant to corrosion, making it ideal for storing and protecting chemicals. It is also lightweight, which makes transportation and installation easier. Additionally, aluminum is non-reactive with most chemicals, ensuring the safety of the stored substances. Overall, aluminum sheets provide a reliable and efficient solution for manufacturing chemical storage cabinets.

- Q: I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- Carbon Arrow In Hand

- Q: iron-based alloys over aluminum in structural members of bridges and buildings?

- Aluminum generally has a better strength-to-weight-ratio. Steel alloys are still used in some of the parts of a typical aircraft, where tensile strength and toughness are the major considerations, over weight. The landing gear, bolts and pins, hinges, bearings, for example. Steel is used for bridges and buildings, because it's a lot *cheaper* than aluminum, and saving weight isn't nearly as critical as it is in aircraft. Steel is stiffer than aluminum, and It's easier and cheaper to make reliable welds in steel as well. Welding aluminum tends to be time consuming and expensive.

- Q: Can aluminum sheets be used for insulation purposes?

- Aluminum sheets are capable of being used for insulation purposes. Due to its high thermal conductivity, aluminum serves as an efficient heat conductor. Nevertheless, in order to enhance insulation efficacy, aluminum sheets are typically combined with other substances. One common example is aluminum foil insulation, which involves combining aluminum foil with materials like foam or fiberglass to establish a heat transfer barrier. The reflective nature of aluminum further aids in deflecting radiant heat, thereby amplifying its insulation capabilities. In summary, although aluminum sheets alone may not offer ample insulation, they can be effectively utilized in conjunction with other materials to construct insulation systems suitable for diverse applications.

Send your message to us

Gold Adhesive ASTM B-209 Standards 3000 Series Smooth/Corrugated/Stucco Embossed Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords