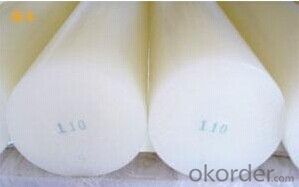

Glass Fiber Textiles Reinforced Zirconia Ceramic Rod

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Zirconia ceramic rods with precision slotted have the advantages of super hardness,high wear-resisting,good corrosion resistance ,high temperature tolerance,, high strength , precision process, high mechanical strength, good chemical stability, polishing surface and so on.

The following data as your reference .

Items | Unit | Data |

Density | g/cm3 | 6 |

Flexural Strength | MPa | 1000 |

Compressive Strength | MPa | 3000 |

Modulus of Elasticity | GPa | 200 |

Impact Resistance | MPa·m1/2 | 8 |

Weibull Modulus | m | 22 |

Vickers Hardness | HV0.5 | 1300 |

Thermal Conductivity | W/mk | <2 |

Highest Application Temperature | °C | 1000 |

Volume Resistivity at 20°C | Ω.cm20 | >1013 |

Dielertric strength | KV/mm | - |

Thermal expansion | X10-6/K | 10 |

Forming methods includes

1,drying pressing

2,isostatic pressing

3,hot pressing casting

The application of our product

1, ceramic shaft for aquatic animals equipment filter pump

2, Ceramic plunger for high pressure cleaner.

3,Wearlessness,resistant acid-base and high intensity ceramic assembly apply to petroleum ,chemical and chemical industry.

4,Wearlesness, corrosion resistance, thermostable parts apply to precision machine.

- Q: Can glass fiber textiles be used for reinforcement in plastics?

- Glass fiber textiles are capable of reinforcing plastics. When utilized as reinforcement in plastics, glass fibers exhibit strength and offer exceptional mechanical properties. They bolster the final plastic composite's strength, stiffness, and impact resistance. In industries like automotive, aerospace, construction, and consumer goods, glass fiber textiles are extensively employed to reinforce plastic parts and components. The amalgamation of glass fibers and plastics results in a composite material that is lightweight, long-lasting, and possesses remarkable tensile strength.

- Q: Are glass fiber textiles suitable for sports and outdoor gear?

- Yes, glass fiber textiles are suitable for sports and outdoor gear. Glass fiber textiles are known for their strength and durability, making them an excellent choice for equipment used in sports and outdoor activities. These textiles have high tensile strength, meaning they can withstand high levels of stress and strain without breaking or tearing. This makes them ideal for applications such as sports apparel, backpacks, tents, and other gear that need to withstand rough handling and harsh weather conditions. Additionally, glass fiber textiles have excellent resistance to UV rays, moisture, and chemicals, further enhancing their suitability for outdoor use. Furthermore, the lightweight nature of glass fiber textiles makes them favorable for sports gear, where agility and mobility are crucial. Overall, glass fiber textiles provide the necessary qualities required for sports and outdoor gear, making them a suitable choice for such applications.

- Q: Polyester fiber fabric clothes will cross it out

- Polyester fibers are absorbent and shrink free textile materials, so the clothes they make do not have what you say. The only consideration is not to use hot water.

- Q: How do glass fiber textiles perform in terms of flexibility?

- Glass fiber textiles are known for their exceptional flexibility. Due to the nature of glass fibers, which are thin and lightweight, these textiles can be easily bent, twisted, or folded without losing their shape or structural integrity. This flexibility makes them highly versatile and adaptable to various applications. They can be seamlessly integrated into composite materials, such as laminates, to enhance their flexibility and mechanical properties. Additionally, glass fiber textiles exhibit excellent resilience, meaning they can withstand repeated bending or stretching without breaking or losing their original form. This makes them ideal for applications that require flexibility, such as in the aerospace, automotive, and sports industries. Overall, glass fiber textiles offer a high level of flexibility, making them a preferred choice for many applications.

- Q: How do glass fiber textiles contribute to stain resistance?

- Glass fiber textiles contribute to stain resistance by their inherent properties. Glass fibers are non-porous and have a smooth surface, which makes it difficult for stains to penetrate and adhere to the fabric. This resistance to absorption prevents liquid stains, such as spills from food or beverages, from seeping into the fabric and causing permanent discoloration. Additionally, the smooth surface of glass fibers makes it easier to clean and remove stains. Unlike other textiles that have rougher surfaces, glass fiber textiles allow stains to be wiped away more easily, reducing the likelihood of permanent staining. Furthermore, glass fibers are also resistant to chemicals and can withstand harsh cleaning agents, allowing for more effective stain removal without damaging the fabric. Overall, the unique properties of glass fiber textiles contribute to their stain resistance, making them a durable and practical choice for various applications.

- Q: How do glass fiber textiles compare to synthetic fiber textiles?

- Glass fiber textiles and synthetic fiber textiles have distinct characteristics that set them apart from each other. Glass fiber textiles are made from fine strands of glass, which are woven or knitted together to create a fabric. They are known for their strength and durability, making them suitable for applications that require high tensile strength and resistance to heat and chemicals. Glass fiber textiles also have excellent dimensional stability, meaning they do not stretch or shrink easily. This makes them ideal for use in reinforced composites, such as in the automotive and aerospace industries, where strength and stability are paramount. On the other hand, synthetic fiber textiles are made from man-made fibers, such as polyester, nylon, or acrylic. These materials are designed to mimic the properties of natural fibers, such as cotton or silk, but with added benefits. Synthetic fiber textiles are typically lightweight, easy to care for, and resistant to wrinkling and shrinking. They also have moisture-wicking properties, making them suitable for sportswear or outdoor gear. Additionally, synthetic fibers can be engineered to possess specific properties, such as flame resistance or UV protection. When comparing glass fiber textiles to synthetic fiber textiles, it is important to consider the intended use and desired properties. Glass fiber textiles excel in applications that require strength, dimensional stability, and resistance to heat and chemicals. Synthetic fiber textiles, on the other hand, are more versatile and can be tailored to specific needs, such as moisture management or comfort. Both types of textiles have their own advantages and are chosen based on the requirements of the particular application.

- Q: Can glass fiber textile be used in insulation?

- Yes, glass fiber textile can be used in insulation. Glass fibers are known for their excellent thermal insulation properties, as they have low thermal conductivity and high resistance to heat transfer. Glass fiber textiles are commonly used in various forms of insulation, such as blankets, batts, and boards, to provide effective thermal insulation in buildings, industrial equipment, and pipelines. The fibers are woven or bonded together to form a textile material, which is then used to trap air pockets and minimize heat flow. Additionally, glass fiber textiles are lightweight, flexible, and resistant to moisture, making them an ideal choice for insulation applications.

- Q: What are the different surface coating methods for glass fiber textile?

- There are several surface coating methods available for glass fiber textiles, each offering unique properties and applications. Some of the most common methods include: 1. Dip coating: In this method, the glass fiber textile is immersed in a liquid coating material, such as a polymer or resin, and then dried or cured to form a protective layer. This method is often used to provide a barrier against moisture, chemicals, or UV radiation. 2. Spray coating: In spray coating, the coating material is atomized into fine droplets and then sprayed onto the glass fiber textile using a specialized nozzle. This method allows for even coverage and can be used to achieve different levels of thickness or texture on the surface. 3. Roll coating: In roll coating, the glass fiber textile is passed through a set of rollers that are coated with the desired material. The coating is transferred from the rollers to the textile, providing a uniform and controlled application. This method is commonly used for applying adhesives or protective coatings. 4. Vacuum deposition: Vacuum deposition involves evaporating or sputtering a thin layer of coating material onto the glass fiber textile in a vacuum chamber. This method is often used to apply metallic or ceramic coatings, providing enhanced electrical conductivity, thermal resistance, or optical properties. 5. Electroplating: Electroplating is a process where a metal coating is deposited onto the glass fiber textile through an electrochemical reaction. This method is typically used to enhance the mechanical strength, corrosion resistance, or aesthetic appearance of the textile. 6. Sol-gel coating: Sol-gel coatings are formed by applying a liquid precursor solution onto the glass fiber textile, which then undergoes a chemical reaction to form a solid coating. This method allows for the incorporation of functional additives, such as nanoparticles or catalysts, to improve specific properties like self-cleaning or anti-fogging. These are just a few examples of the different surface coating methods for glass fiber textiles. The choice of method depends on the desired properties, performance requirements, and intended applications of the coated textile.

- Q: Can glass fiber textiles be used in sportswear?

- Yes, glass fiber textiles can be used in sportswear. They are known for their durability, strength, and lightweight properties, making them suitable for various sports activities. Glass fiber textiles can provide athletes with enhanced performance and protection, offering qualities such as moisture-wicking, breathability, and resistance to abrasion. However, it is important to consider the specific sport and its requirements before incorporating glass fiber textiles into sportswear designs.

- Q: Are glass fiber textiles resistant to solvents or cleaning agents?

- Yes, glass fiber textiles are generally resistant to solvents and cleaning agents. They can withstand exposure to a wide range of chemicals without significant degradation or damage.

Send your message to us

Glass Fiber Textiles Reinforced Zirconia Ceramic Rod

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches