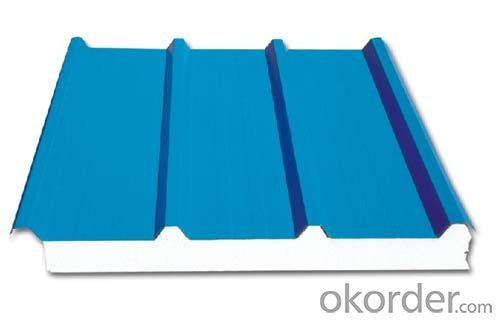

GI Prepainted corrugated steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,SGHC,DX51D.. | Thickness: | 0.14-3.0mm |

| Place of Origin: | Shanghai China (Mainland) | Brand Name: | Model Number: | 600-1250mm | |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | coated ,galvanized |

| Application: | building ,house,construction | Special Use: | Wear Resistant Steel | Width: | 600-1250mm |

| Length: | Any length | sample: | free available | quality: | first class |

| stock: | 5766tons | company type: | manufacturer & exporter | product name: | prepainted galvanized corrugated steel sheet |

Packaging & Delivery

| Packaging Detail: | 1.packed in bundles 2.waterproof packing 3.packed by steel strip 4.as per to clients |

| Delivery Detail: | within 5-20 days after receipt deposit or L/C at sight. |

Specifications

prepainted galvanized corrugated sheel sheet

1.Thickness:0.14-3.0mm

2.Width:600-1250mm

3.In stock

4.Fast delivery

prepainted galvanized corrugated steel sheet | |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | DX51D SGCC, DC51D,SPCC |

Thickness | 0.14-3.0mm |

Width | 600-1250mm(1250,1220,1000, 980mm, 900mm ,840mm, 820mm, 750mm) |

Coating | PE ,PVDF, HDP ,galvanized(30-300g), galvalume (AZ80) |

Color | According to RAL card |

Length | cut as client’s request, but considering the transportation , its better to cut less than 5.8 meter (for 20’ft container) , or 11.8 meter (for 40’ft container). |

Remarks | 1.Payment terms:T/T, L/C 2.Trade terms:FOB, CNF, CIF 3.Port:Shanghai 4.Supply ability:5000Tons/month 5.Delivery time: within 15-20 days after receiving the deposit. |

- Q: Can steel sheets be used in the manufacturing of furniture?

- Yes, steel sheets can be used in the manufacturing of furniture. They are commonly used to create strong and durable structural components such as frames, legs, and supports in various types of furniture such as tables, chairs, and cabinets. Steel sheets offer excellent strength and stability, making them suitable for heavy-duty applications in furniture manufacturing.

- Q: What is the average lifespan of steel sheets used for roofing?

- The lifespan of steel sheets used for roofing can vary based on several factors. Nevertheless, high-quality steel roofing sheets are designed to be extremely durable and long-lasting. On average, these steel sheets can endure for 40 to 70 years or potentially even longer if properly maintained and cared for. The longevity of steel roofing sheets can be influenced by factors such as the steel type and thickness, the coating or finish quality, the climate and weather conditions in the area, and the level of maintenance. Conducting regular inspections, cleaning, and repairs as necessary can help extend the lifespan of the steel sheets and ensure their good condition for many years. It is always advisable to seek guidance from roofing professionals or manufacturers for specific guidelines and recommendations regarding the lifespan of steel sheets used for roofing in a particular context.

- Q: Are the steel sheets suitable for solar panel mounting?

- Yes, steel sheets are suitable for solar panel mounting. Steel is a strong and durable material that can provide a stable and secure base for solar panels. It has the necessary strength to support the weight of the panels and withstand various weather conditions. Additionally, steel sheets can be easily fabricated and customized to fit the specific requirements of the solar panel installation. Overall, using steel sheets for solar panel mounting can ensure a reliable and long-lasting foundation for the panels.

- Q: Can steel sheets be used for storage cabinets?

- Yes, steel sheets can be used for storage cabinets. Steel is a durable and strong material that is commonly used in storage cabinets due to its ability to withstand heavy loads and resist corrosion. Additionally, steel sheets can be easily molded and welded to create different sizes and shapes of cabinets, making them a versatile choice for storage solutions.

- Q: Can steel sheets be used for magnetic shielding?

- Yes, steel sheets can be used for magnetic shielding as they have high magnetic permeability, meaning they can redirect and absorb magnetic fields, providing effective shielding against magnetic interference.

- Q: How do steel sheets compare to wood sheets?

- Steel sheets and wood sheets have distinct differences in terms of strength, durability, and use cases. Firstly, steel sheets are known for their exceptional strength and durability. They can withstand heavy loads, extreme weather conditions, and are highly resistant to warping, rotting, and insect damage. Wood sheets, on the other hand, are less robust and can be vulnerable to moisture, termites, and decay if not properly treated or maintained. In terms of versatility, steel sheets offer a wide range of applications. They are commonly used in construction, automotive, and manufacturing industries due to their high tensile strength and structural stability. Wood sheets, on the other hand, are often used in interior design, furniture making, and smaller-scale construction projects due to their natural aesthetic appeal and ease of manipulation. Additionally, steel sheets are fire-resistant, making them a safer option compared to wood sheets, which are combustible and can contribute to the spread of fire. Steel sheets also have a longer lifespan, requiring less maintenance and replacement compared to wood sheets, which may need regular refinishing, sealing, or replacement due to wear and tear. However, wood sheets have their advantages as well. They are typically more cost-effective than steel sheets, making them a popular choice for budget-conscious projects. Wood sheets also have better insulation properties, providing natural warmth and soundproofing qualities. Ultimately, the choice between steel sheets and wood sheets depends on the specific requirements of the project, including factors such as budget, desired aesthetics, structural needs, and environmental considerations.

- Q: Are the steel sheets suitable for outdoor applications?

- Certainly, steel sheets prove to be a fitting option for outdoor applications. Boasting durability and strength, steel emerges as a material capable of withstanding diverse weather conditions and environmental elements. Its resistance to rust and corrosion renders it particularly ideal for outdoor utilization. Moreover, steel sheets can be subjected to treatment or coating processes, thereby augmenting their resilience against moisture and other external factors, further amplifying their appropriateness for outdoor applications. Whether the purpose entails construction, manufacturing, or decorative endeavors, steel sheets present themselves as a dependable selection for outdoor projects.

- Q: How are steel sheets made?

- Steel sheets are made through a process called hot rolling, where steel ingots are heated and passed through a series of rolling mills to reduce their thickness and shape them into flat sheets.

- Q: What is the average weight of galvanized steel sheets?

- The average weight of galvanized steel sheets can vary depending on their thickness and dimensions. However, a common range for galvanized steel sheets is between 30 to 150 pounds per sheet.

- Q: What is the average bending radius for steel sheets?

- The average bending radius for steel sheets varies depending on the thickness, grade, and type of steel being used. However, on average, the minimum bending radius for mild steel sheets is generally around four times the sheet thickness. For example, if the sheet thickness is 1.6mm, the minimum bending radius would be approximately 6.4mm. It is important to note that this is a general guideline, and specific bending requirements may differ based on the specific application and desired outcome.

Send your message to us

GI Prepainted corrugated steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords