Geotextil Bauhaus High-Density Polyethylene Geomembrane with Highest Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Type:HDPE geomembrane

Material: High-density polyethyle Material Low-density Polyethylene

Thickness:0.1mm~3.0mm

Roll width:1m~8m Roll length:50m~100m

Color:Black or at your request

Density: 0.94g /cm3

Temperature range: -60oC -- +60oC

Life time: more than 50 years

Executive standard: GB/T 17643-2011

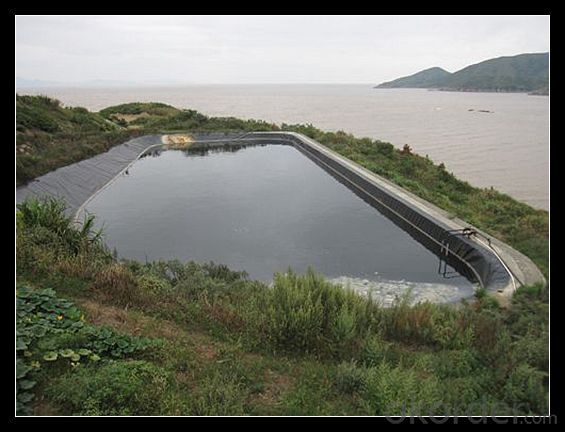

Geomembranes are the most widely used products for solid waste containment (such as landfill liners), mining, and water containment applications.

our factory uses the highest quality resins to manufacture the widest selection of high density polyethylene (HDPE) and linear low density polyethylene (LLDPE) geomembrane products available in either a black, green, white or Conductive upper surface, and in either a smooth or textured single or double-sided surface

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile seam construction how to do

- Sewing of geotextiles All sutures must be carried out continuously (for example, spotting is not allowed). Before the overlap, the geotextile must overlap at least 150mm. The minimum stitch is at least 25 mm from the weaving edge (the edge of the material exposed). The seam of the geotextile seam is covered by a single line of thread lock. The line used for suturing should be a resin material with a minimum tension of more than 60N and is resistant to chemical corrosion and UV resistance comparable to or beyond the geotextile. Any "missing needle" on the sewn geotextile must be re-sewn in the affected area. It is necessary to take appropriate measures to prevent the soil, particulate matter or foreign matter from entering the geotextile after installation. Cloth lap according to the terrain and the use of functions can be divided into natural lap, seam or welding. Geotextile manufacturers, for your answer

- Q: Can geotextiles be used for erosion control in mining sites?

- Yes, geotextiles can be used for erosion control in mining sites. Geotextiles are permeable fabrics that are often used to stabilize soil and prevent erosion by separating, filtering, and reinforcing different layers of soil. In mining sites, where the land is disturbed and susceptible to erosion, geotextiles can be employed as an effective erosion control measure. They can be used to cover exposed soil, reinforce slopes, and retain sediment, minimizing erosion and protecting the ecosystem.

- Q: The vertical permeability coefficient of 400 g per square filament geotextile is generally how much

- 1.0 × 10-1cm / sK × (10-1-10-3) I specialize in the production of geotechnical materials

- Q: Geotextile a square meter how much money

- I professional production, ranging from 3-10 yuan

- Q: How do geotextiles help with soil reinforcement in mechanically stabilized earth walls?

- Geotextiles help with soil reinforcement in mechanically stabilized earth walls by providing a strong and stable support system. They act as a barrier between the soil layers, preventing erosion and maintaining the integrity of the wall. The geotextiles distribute the load of the soil evenly, reducing the potential for settlement or failure. Additionally, they enhance the overall stability of the structure by increasing the friction between the soil layers, improving the resistance to lateral forces.

- Q: Can geotextiles be used in underground storage tank installations?

- Yes, geotextiles can be used in underground storage tank installations. Geotextiles are commonly used as a protective barrier between the tank and the surrounding soil, providing filtration and separation functions. They can help prevent soil erosion, control groundwater flow, and provide additional stability to the tank system.

- Q: What is the role of geotextiles in road construction?

- Geotextiles play a crucial role in road construction by providing reinforcement, filtration, and separation functions. They are used to enhance the stability and longevity of roads by preventing the mixing of different soil layers, reducing erosion and maintaining proper drainage. Additionally, geotextiles help to distribute loads more evenly, preventing the formation of cracks and potholes, thus improving the overall performance and durability of the road.

- Q: What are the specifications for geotextiles in drainage projects?

- The specifications for geotextiles in drainage projects typically include factors such as tensile strength, permeability, durability, and UV resistance. The geotextiles should have a high tensile strength to withstand the stress and load from the surrounding soil and water. They should also have a permeable structure to allow water to pass through while preventing soil particles from clogging the drainage system. Durability is crucial to ensure a long service life, and UV resistance helps to maintain the geotextiles' performance even when exposed to sunlight.

- Q: How do geotextiles help with reinforcement of soil slopes?

- Geotextiles help with the reinforcement of soil slopes by providing a stable and strong barrier that prevents soil erosion. They act as a protective layer, distributing the weight and forces evenly, enhancing the stability of the slope. Additionally, geotextiles separate the soil layers, preventing intermixing and promoting drainage, which further contributes to the reinforcement of the slope.

- Q: Small-scale geotextile and geotextile materials have no effect on environmental protection?

- The impact on the environment is certain, but the benefits outweigh the disadvantages. Geotextile production for environmental protection is both convenient and safe, has been widely used to solve the roadbed subsidence and frosting mud problem, for earth and rock dam drainage system, underground drainage pipes, soft foundation reinforcement, a variety of embankment slope slope And other works of the filter layer. In addition, it can also be used for soil reinforcement materials, so that the soft foundation reinforcement or the construction of light retaining wall, at the same time, but also reduce the embankment under the pore water pressure. And so on, not only to contribute to the cause of environmental protection, but also to stimulate economic development. Geotechnical materials development and application are very good, very broad development prospects. Hope to adopt.

Send your message to us

Geotextil Bauhaus High-Density Polyethylene Geomembrane with Highest Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords