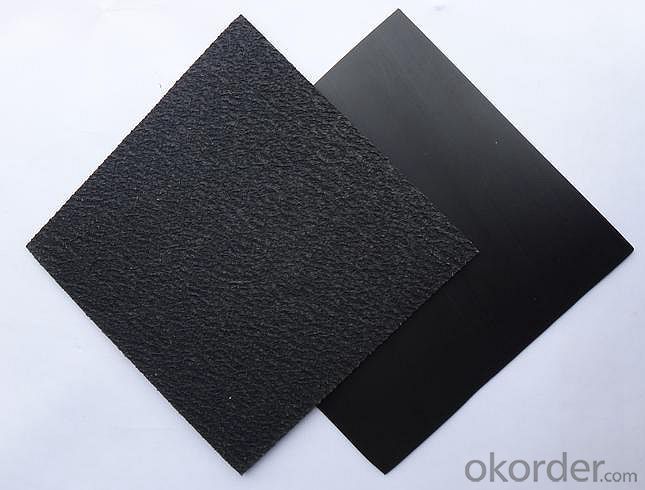

Para Que Sirve El Geotextil - Best Quality Linear Low-Density Polyethylene Geomembrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications:

Flexible membranes are used in a variety of applications, such as:

Landfill lining

to protect the ground water from contamination.

Landfills capping

to prevent fluid flow in the landfill, to trap and properly vent the gases generated during decomposition of organic waste and to permit efficient revegetation and restoration of the area.

Water reservoirs

for collecting rain-water before it reaches the sea.

Reservoirs for waste-water

to protect the groundwater sources or streams.

Pond-lining

for artificial lakes and irrigation of farms.

Irrigation canals

an economic alternative to concrete and compacted earth for transporting water and irrigating large areas. Also used to reduce seepage from existing deteriorated concrete linings.

Protection of lake banks

for soil stabilization.

Tunnels

protecting the structure against humidity and water pressure.

Earth dams

for soil stabilization.

Underground insulation

of chemical plants, petrol stations & roads to prevent chemicals, oil etc. from polluting the underground water in case of a leakage.

Mining

for preventing contamination of the soil and underground water and permitting extraction of precious metals by heap leaching, using chemical solutions.

Tanks

secondary lining for preventing pollution in case of leakage or chemical spill.

Insulation of buildings & construction projects

Evaporation basins

Aquaculture

Water reservoirs for fish breeding.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

- Q: Can geotextiles be used in contaminated soil?

- Yes, geotextiles can be used in contaminated soil. Geotextiles are often used in contaminated soil remediation projects to provide separation, filtration, and reinforcement. They help to control the migration of contaminants, prevent soil erosion, and improve the stability of the soil. By effectively containing and treating the contaminants, geotextiles contribute to the overall success of soil remediation efforts.

- Q: Production of geomembrane equipment which are such as the production of geotextile need to press machine, open charter, carding machine, etc.

- Mixing machine, screw extruder, heating die, circulating fan, traction machine, into a roll machine.

- Q: How do geotextiles contribute to the sustainability of construction projects?

- Geotextiles contribute to the sustainability of construction projects in several ways. Firstly, they can act as a barrier to prevent soil erosion, which helps to protect the surrounding environment and maintain the integrity of the construction site. Secondly, geotextiles can enhance the stability and longevity of structures by providing reinforcement and improving soil mechanics. This reduces the need for excessive use of materials and resources, making construction projects more sustainable. Additionally, geotextiles can aid in the conservation of water resources by promoting proper drainage and preventing waterlogging. Overall, the use of geotextiles in construction projects helps to minimize environmental impacts while improving the efficiency and durability of structures, contributing to long-term sustainability.

- Q: What are the key factors affecting the durability of geotextiles?

- The key factors affecting the durability of geotextiles include the material composition, UV exposure, chemical resistance, physical properties, installation and maintenance practices, and environmental conditions such as temperature and moisture levels.

- Q: Can geotextiles be used in railway track stabilization?

- Yes, geotextiles can be used in railway track stabilization. Geotextiles provide reinforcement and separation functions, preventing the mixing of materials and improving the stability of the track. They can help distribute loads, reduce deformation, and enhance the overall performance and lifespan of the railway track.

- Q: what is the purpose of geotextile on gabion walls.?

- Geotextiles are fabrics associated with soil, earth or rocks. Gabions were earth filled barricades meant to halt enemy fire during battle. I'm guessing geotextiles on gabion walls more effectively hold back the earth or filler. They might have well suited permeability or retentive qualities for gabions. There are a few other definitions for gabions. But this is the militaristic definition. Gabions are also used in dams and such. In this case, geotxtiles might have good properties for being submerged in water and still retaining whats inside the gabions.

- Q: Geotextile with ordinary non-woven like not? The

- Many kinds of non-woven fabrics can do geotextiles, such as sewing non-woven, acupuncture non-woven fabrics.

- Q: How to build a good 12 by 24 brick wall

- How to build a good 12 by 24 brick wall

- Q: Can geotextiles be used in geogrid reinforced slopes?

- Yes, geotextiles can be used in geogrid reinforced slopes. Geotextiles are often used in conjunction with geogrids to enhance their performance and provide additional benefits such as filtration, separation, and erosion control. The geotextile acts as a barrier to prevent fine particles from migrating through the geogrid, while still allowing water to pass through. This combination of geotextiles and geogrids helps to improve the stability and longevity of reinforced slopes.

- Q: What is the meaning of geotextile anchoring?

- Geotextile anchorage: is the geotextile in the construction of civil engineering construction in the slope of the fixed, to prevent the geotextile movement.

Send your message to us

Para Que Sirve El Geotextil - Best Quality Linear Low-Density Polyethylene Geomembrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords