Geomembrana Circular Dimple Composite Geomembrane - High Quality, Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

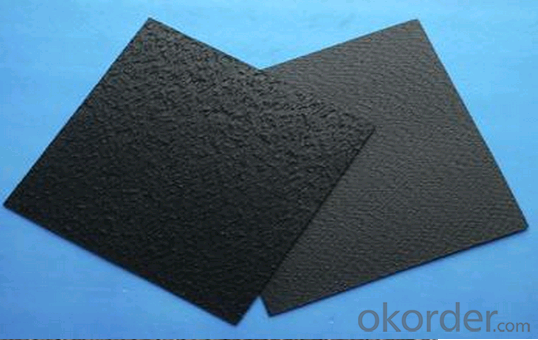

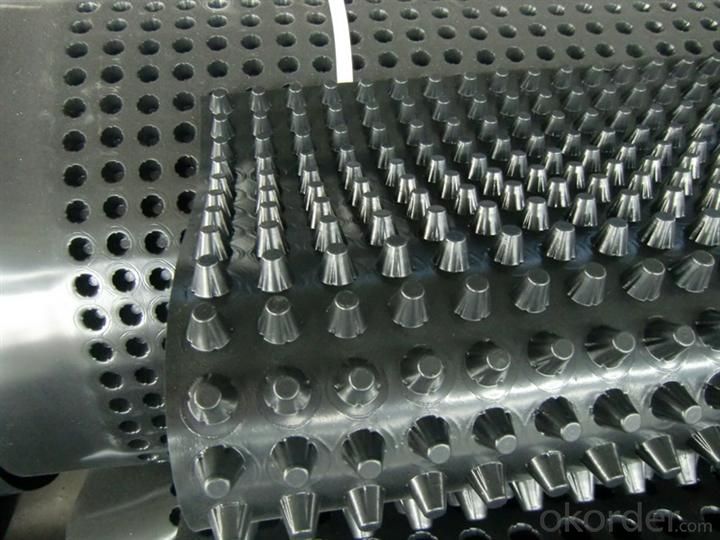

EltMembrane-CDG series of geomembrane is manufactured from High Density Polyethylene resins. Produced by extruding plastic sheet into dimple shape.These dimples,in spatial structure with certain height. Can resist long-term high pressure without deformation. On the top of the dimples, there is filtration geotextile to make sure the drainage channel ruing well without any block for any articles. For example,filling particles or concrete.

Advantages

1. strong viscosity, cold pressing sensitive

2. color white/black

3. accurate size cutting

4. custom size offered without any surcharge

Application

1, Municipal projects

2,Landfill treatment projects

3,Waste water treatment

4,Mineral waterproofing

| Composite Dimple geomembrane | |||||||

| NO. | Item Name | Technical requirements | |||||

| H10-1.0 | H20-1.0 | H10-1.5 | H20-1.5 | H10-2.0 | H20-2.0 | ||

| 1 | Tensile strength N/<5cm> ≥ | 400 | 400 | 500 | 500 | 700 | 700 |

| 2 | Elongation at break % ≥ | 200 | 200 | 300 | 300 | 400 | 400 |

| 3 | Dimensional strength Mpa ≥ | 400 | 320 | 450 | 370 | 500 | 420 |

| 4 | Dimensional stability % | ±2 | |||||

| 5 | Low tempreture impact brittle property | -35℃ crack-free bending | |||||

| 6 | Longitudinal flow capacity cm3/s( hydraulic pressure 5Kpa) | 5.6 | 8.6 | 5.6 | 8.6 | 5.6 | 8.6 |

| 7 | Longitudinal flow capacity cm3/s( hydraulic pressure 350Kpa) | 15.2 | 18.2 | 15.2 | 18.2 | 15.2 | 18.2 |

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q: What is the role of geomembranes in mining tailings management?

- Geomembranes play a crucial role in mining tailings management by providing a barrier between the tailings and the environment. They are used to contain and prevent the contamination of surrounding soil and water sources by the potentially harmful substances found in the tailings. Additionally, geomembranes can help facilitate the process of tailings dewatering and consolidation, ultimately aiding in the overall management and safety of mining operations.

- Q: Is electrothermal?film safe?

- Electrothermal?film system has extremely high security, having no security risk, which is a very mature product. After testing by related departments, its insulation grade, voltage endurance capability, leakage current, flame resistance have reached the corresponding national standards.

- Q: What are the technical points of the lioghtweight foam?concrete?

- 1. To clean the surface and ensure that there is no dust and dirt of the grassroots, for smooth, solid, light pressure, does not allow rugged, loose and sand off ash and other defects. 2. To make a good preparation of the materials, the foaming agent, additives, cement and auxiliary materials should be transported to the designated place for storage. 3. It should be leveled according to the design. First, take use of the cement mortar according to 2.5x2.5m to determine the height of the slope. 4. To start the foaming machine to start to work, and then start the host. To sent the cement into the agitator with the help of the conveyor?belt/band carrier. And after it is mixed uniform to start the transportation system of foam conveying system and high-pressure pump. And then mix the concrete composite material averagely and transport them to the disignated construction area to cast. 5. According to the requirements of the construction, the professionals will smooth the castin foam concrete. (with help of the smooth floating ruler) Because after it is being smooth, the surface of the foam cement will produce a little air void which will have a bad effect of the surface of the waterproof construction. It is suggested to establish the 70% final set of the casting foam concrete and use the cement mortar to smooth and protect. 6. When the integral casting of foam concrete has reached 4000 square meters and the final set of the concrete has up to 70%( It is generally 25 centigrade and 36 hours). The cut of the dividing joint should be in time. And the width of the dividing joint should be bigger than 4x4m. The the width and depth of cutting of every dividing joint should be calculated by 1/800 telescopic value of the thermal efficiency expansion. The deepth of the width of cutting is 1.5x3.0cm, the elastic sealing material will be sealed in after the cutting.

- Q: How do geomembranes help in preventing soil compaction?

- Geomembranes act as a barrier between the soil and external forces, such as heavy machinery or vehicles, which helps in preventing soil compaction. By distributing the weight over a larger area, geomembranes reduce the pressure applied directly on the soil, minimizing the chances of compaction.

- Q: How to clean computer keyboard film?

- There is not anything particular about cleaning the keyboard protective film, you can directly use clean water or add a little washing powder or liquid detergent, which have no problem as long as they are abstergent, but pay attention to let it dry naturally after cleaning, and do not expose to the sun or be pulled, therefore, it is not easy to deform and does not coincide with the keyboard.

- Q: Are geomembranes resistant to biodegradation?

- Yes, geomembranes are typically resistant to biodegradation. They are made from synthetic materials such as plastics or rubbers, which have a low susceptibility to decomposition by biological organisms. This resistance allows geomembranes to maintain their integrity and performance over extended periods of time, making them reliable for various applications in environmental protection, waste containment, and water management.

- Q: What are the materials of the geomembrane?

- Mainly include polyvinyl chloride (PVC) and polyethylene (PE), corrosion-resistant, EVA (ethylene & # 47 geomembrane taking plastic film as anti-seepage base material, good extensibility. Currently, they are a kind of polymer chemistry flexible material, the material used for seepage-proofing at home and abroad is plastic film, high?adaptability?to the?deformation; vinyl acetate copolymer), smaller proportion, and design use ECB (ethylene vinyl acetate modified bitumen blend geomembrane) in tunnel application, low temperature resistance, good anti-frost?property. , geotechnique impermeable material combined with non-woven fabric. Its anti-seepage property mainly depends on the anti-seepage property of plastic film.

- Q: What are the sticking methods of computer film?

- The methods of sticking film for computer screen: 1, Generally, if you dig the corner of the laptop protective?film with yuor fingers, it is very easy dig up a corner, and then pull the corner to tear off the laptop protective?film. 2, if it can't be digged up with fingernail, you can prepare two glue to stick a corner of the bottom edge, stick up a corner of the electrostatic film, and then pull the corner to peel off laptop protective film easily. Attention: General protective film is electrostatic film, which can be used repeatedly, so try not to use sharp things to help to tear off the film, which may result in failure to reuse.

- Q: Is the new crystal steel door film expensive?

- It is not expensive. ① , new/ crystal steel door film/ special film for cabinets/ frontal adhesive/ wooden, the price is 8 yuan. ② new/ crystal steel doors film/ cabinet glass door self-adhesive film, the price is more than 9 yuan.

- Q: Does electric heating film consume a lot of electricity?

- The electric heating film is very energy saving and comfortable.

Send your message to us

Geomembrana Circular Dimple Composite Geomembrane - High Quality, Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords