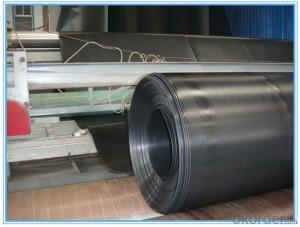

Geomembrane Indonesia

Geomembrane Indonesia Related Searches

Hdpe Pipe IndonesiaHot Searches

Geomembrane For Sale China Pvc Geomembrane China Geomembrane Roll Sheet Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Price Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geomembrane Market Size Wholesale Hdpe Geomembrana Wholesale Liner Geomembrane Geomembrane Liner Supplier Wholesale Geomembrane China Pvc GeomembraneGeomembrane Indonesia Supplier & Manufacturer from China

Okorder.com is a professional Geomembrane Indonesia supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geomembrane Indonesia firm in China.Hot Products

FAQ

- Yes, geomembranes can be used in green roof systems. Geomembranes are often used as a waterproofing layer to prevent water leakage and protect the roof structure. In green roof systems, they are installed beneath the growing medium and vegetation to retain water and create a barrier between the roof and the vegetation, ensuring proper drainage and preventing damage to the underlying structure.

- nan

- 1. First to go to the site to see if there is a condition of installing the keel: Look at the scene to make sure the wall is completed, and woodworking processing part is qualified, the area that need to be plastered should be completed first. First part plastering carpentry part we proposed must be in accordance with the requirements to do, to advance the processing of.2. entering the construction site conditions Licensor hole size lamp, air outlet, first part is fixed according to the design Aluminum Alloy keel keel carpentry requirements drawing well, attention must be right angle connecting to smooth, flat, dense.3. lamp holder, tuyere, light tube plate to and around the keel level, and firmly cannot swing can smooth.4. smoke, ceiling lamps, the first position to make a wooden frame, wooden frame the bottom surface should be polished, and pay attention to the level of height is too low, it is easy to show a trace of.5. before installing ceiling, carefully check the keel joints are solid and smooth, the spray head to stick on the white tape, an outlet should be well handled. When loading the smallpox to first from the middle to both sides of the fixed, while paying attention to size on both sides and pay attention to welding seam to the final straight angle position, pay attention to smooth. Around the well to the smallpox pruning removes. To perfect income effect on the edge. Turn on the light hole. To mark the position of the lamp hole , and carefully stick the PVC lamp ring carefully and accurately on the bottom of the soft film and then remove the excessive smallpox after it is firm. Find the position of the outlet and the light pipe handicap, just as the surroundings, to install the soft film to the aluminum alloy keel, pay attention to keep the angle be smooth.

- Yes, geomembranes are typically resistant to thermal expansion. They are designed to withstand changes in temperature without significant expansion or contraction, which is one of the reasons why they are commonly used in construction and environmental containment applications.

- Yes, geomembranes can be used in agriculture. They are often utilized for various applications such as lining irrigation ponds, reservoirs, and canals to prevent water leakage and seepage. Additionally, geomembranes can be used for lining manure storage pits, silage bunkers, and other agricultural waste containment structures to prevent environmental contamination.

- Yes, geomembranes can be used in wastewater treatment lagoon covers. Geomembranes are often used as impermeable liners or covers to prevent the leakage of wastewater from lagoons. They provide a barrier to contain the wastewater and protect the surrounding environment from contamination. Additionally, geomembranes help to minimize evaporation and control odors in wastewater treatment lagoons.

- Yes, geomembranes can be used in rooftop gardens. They are commonly used as a protective barrier between the rooftop and the garden soil, preventing water leakage and root penetration. Additionally, geomembranes can help retain moisture in the soil and provide a stable foundation for plants, making them a suitable choice for rooftop gardening.

- nan

- It is easy to weld the geotextiles that manual rolling and paving is enough. The surface should be flat with some deformation allowance left. The long or short nonwoven geotextiles are often bonded by lapping, seaming and welding. The seamed and welded overlap is generally more than 0.1m wide. The lapped overlap is generally more than 0.2m wide. For geotextiles with long exposure time, methods of welding and seaming are recommended. Continue seaming until the all the work is completed. (disconnected seaming is not allowed.) Before being bonded, the overlaps should not be less than 150mm wide. The minimum distance of seams to the edges (the exposed edge of material) is 25mm. The thread for seaming should be made from resin with tensile strength no less than 60N, with chemical resistance and UV resistance that are the same with that of geotextile or exceed that of geotextile. Any "missed stitch" should be avoid. Actions should be taken accordingly to prevent emission of soil, particulate matters or foreign matters.

- nan

- 1. First to go to the site to see if there is a condition of installing the keel: Look at the scene to make sure the wall is completed, and woodworking processing part is qualified, the area that need to be plastered should be completed first. First part plastering carpentry part we proposed must be in accordance with the requirements to do, to advance the processing of.2. entering the construction site conditions Licensor hole size lamp, air outlet, first part is fixed according to the design Aluminum Alloy keel keel carpentry requirements drawing well, attention must be right angle connecting to smooth, flat, dense.3. lamp holder, tuyere, light tube plate to and around the keel level, and firmly cannot swing can smooth.4. smoke, ceiling lamps, the first position to make a wooden frame, wooden frame the bottom surface should be polished, and pay attention to the level of height is too low, it is easy to show a trace of.5. before installing ceiling, carefully check the keel joints are solid and smooth, the spray head to stick on the white tape, an outlet should be well handled. When loading the smallpox to first from the middle to both sides of the fixed, while paying attention to size on both sides and pay attention to welding seam to the final straight angle position, pay attention to smooth. Around the well to the smallpox pruning removes. To perfect income effect on the edge. Turn on the light hole. To mark the position of the lamp hole , and carefully stick the PVC lamp ring carefully and accurately on the bottom of the soft film and then remove the excessive smallpox after it is firm. Find the position of the outlet and the light pipe handicap, just as the surroundings, to install the soft film to the aluminum alloy keel, pay attention to keep the angle be smooth.