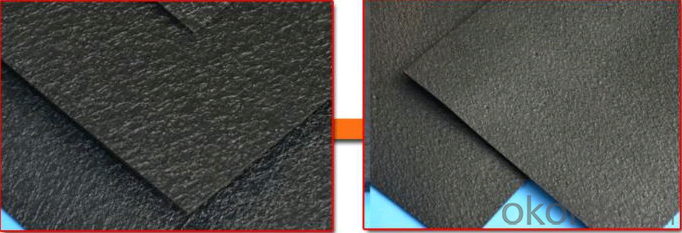

Posa Geomembrane Compound Geomembrane Composite with Two Geotextiles and One Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Geomembranes are generally considered to be made from continuous, highly impermeable, extruded flexible sheets of either HDPE (High Density Polyethylene) or LDPE (Low Density Polyethylene). However, it is also possible to tightly weave small tape fibres of these polymers so as to achieve (either directly or by subsequent treatment) an impermeable membrane. Predominantly, the continuous extruded sheets are used for water containment or waste disposal linings. These inevitably involve the lining of soil slopes and, in order to increase the frictional characteristics of the membranes, so as to resist sliding, one or both sides of geomembranes can be provided with roughened or raised profile surfaces.

Applications:

Geomembranes have a very low coefficient of permeability - much lower than most clays and natural soils. HDPE, in particular, is highly resistant to any form of chemical or biological attack. It is also very resistant to U.V. degradation. Many geomembranes are so inert that they cannot be glued together - the chemical reactions of adhesives do not work on them - they have to be welded together by heat. Their inert nature and long life characteristics make HDPE geomembranes ideal to act as liners for liquid chemical reservoirs, fresh-water reservoirs, animal waste containers, basal linings and top capping layers for waste disposal sites. During installation, HDPE geomembrane edges are sealed to one another with a double heat welded joint. The gap between the two welds is checked for leakage using an air pressure test. Many users consider that HDPE is the ideal material for the purpose of lining water and waste disposal sites because of its proven long term stability and resistance to chemical attack, but in addition to HDPE, there is LDPE, for less demanding applications such as fresh water retention and a membrane reinforced with a polyester reinforcing fabric for use where higher in-plane stresses have to be absorbed.

No. | Item | Test Value | |||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 1.8mm | 2.0mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.94 | |||||||

2 | Strength at yield,N/mm | 11 | 15 | 18 | 23 | 27 | 30 | 38 | 45 |

3 | Strength at break ,N/mm | 21 | 28 | 33 | 43 | 51 | 57 | 71 | 85 |

4 | Elongation at yield,% | 13 | |||||||

5 | Elongation at break,% | 700min | |||||||

6 | Tear Resistance N | 93 | 125 | 156 | 187 | 219 | 249 | 311 | 373 |

7 | Puncture Resistance N | 263 | 352 | 440 | 530 | 618 | 703 | 881 | 1059 |

8 | Stress Crack Resistance, hrs | 400 | |||||||

9 | Carbon Black Content, % | 2.0-3.0 | |||||||

Carbon Black Dispersion | 1 or 2 | ||||||||

10 | Standard OTI Min | 100 | |||||||

High Pressure OTI Min | 400 | ||||||||

11 | Impact Cold Crack at -70°C | Pass | |||||||

12 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | |||||||

13 | Dimensional Stability (%) | ±2 | |||||||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: How to lay the colorful geomembrane.

- It is easy to use, not shovel wall, and not groundbreaking. It can be directly pasted on the cement wall could be pasted. It can not be burned by fire and wetted by water. Generally speaking, it is very good.

- Q: What are the differences between seepage-proof geomembrane and impermeable geomembrane?

- Just different names, products are the same.

- Q: Can geomembranes be used in canal lining?

- Yes, geomembranes can be used in canal lining. Geomembranes are impermeable materials that provide a barrier against water seepage and are commonly used in various civil engineering applications, including canal lining. They help prevent water loss and increase the efficiency of water conveyance systems by minimizing leakage through the canal walls.

- Q: How to create a new fish pond water

- With modified asphalt covered, and then on the cement tiles and so no problem.

- Q: Are geomembranes suitable for use in agricultural applications?

- Yes, geomembranes are suitable for use in agricultural applications. They are effective in preventing soil erosion, managing water resources, and controlling the spread of pollutants. Geomembranes also help in improving crop yield and reducing the need for chemical fertilizers, making them a valuable asset in sustainable agriculture practices.

- Q: What are the features of seepage-proof geomembrane HDPE geomembrane exclusive for solid waste landfill ?

- HDPE geomembrane : ① excellent chemical resistance (corrosion resistance); ② outstanding ability of stress cracking resistance (environmental stress cracking resistance ); ③ lowest permeability; ④ excellent UV resistance; ⑤ stable vertical performance at low temperature; composite geo-membrane performance: Composite geo-membrane (composite anti-seepage membrane )is divided into one cloth and one membrane, two cloth and one membrane, 4-6m wide range , 200-1500g / m?. physical and mechanical property indexes such as tensile, tear, bursting resistance are high. The product has high strength, good extensibility, large modulus?of?deformation, acid and alkali resistant, anti-corrosion, anti-seepage property. It can meet the needs of seepage prevention, insulation, reinforcement abd anti-cracking fixing in water?conservancy, municipal engineering, construction, transportation, subways, tunnels and so on. Because it uses high polymer material and adds antioxidant during production process, it can be used in unconventional temperature environment. It is commonly used in seepage-proof treatment in dams, drainage ditch and antifouling treatment in waste storage.

- Q: how to use wallpaper basilemma

- it is better to use wallpaper treasure, the base of basilemma is too soft, a cut can make the wallpaper broken.

- Q: Are geomembranes resistant to root penetration?

- Yes, geomembranes are generally resistant to root penetration due to their impermeable and strong nature, which prevents plant roots from breaking through or growing into the material.

- Q: How are geomembranes tested for seam strength?

- Geomembranes are typically tested for seam strength through a series of rigorous tests and inspections. These tests often involve subjecting the geomembrane seams to various mechanical stresses and strains, such as tensile and shear forces, to evaluate their strength and durability. Additionally, non-destructive techniques like ultrasound or visual inspection are used to detect any potential defects or weaknesses in the seams. These comprehensive testing methods ensure that the geomembranes meet the required standards and can effectively withstand environmental conditions.

- Q: Can geomembranes be used in artificial lake construction?

- Yes, geomembranes can be used in artificial lake construction. Geomembranes are impermeable liners made from synthetic materials that are designed to prevent the seepage of water. They are commonly used in various construction projects, including artificial lake construction, to provide a reliable barrier and ensure the containment of water within the lake.

Send your message to us

Posa Geomembrane Compound Geomembrane Composite with Two Geotextiles and One Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords