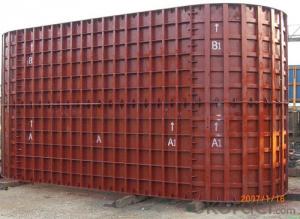

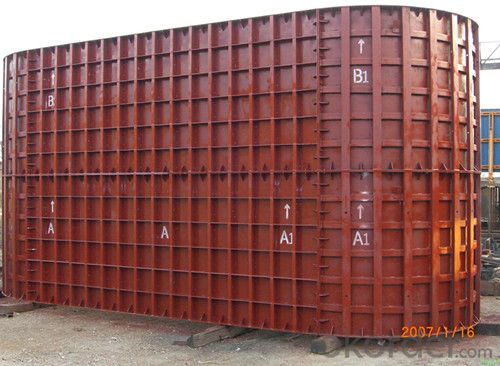

Steel Formwork for Skyspare Export to Indonesia

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q: What are the common accessories and attachments used with steel formwork systems?

- Enhancing functionality and efficiency, steel formwork systems utilize various common accessories and attachments. These include: 1. Securing the steel formwork panels together, formwork clamps offer stability and prevent any movement during concrete pouring. 2. Connecting the steel formwork panels and maintaining their desired position, formwork ties evenly distribute pressure to prevent bulging or deformation. 3. Providing additional strength and stability, adjustable steel props support the weight of the formwork and freshly poured concrete, ensuring proper alignment and preventing collapse. 4. Attaching the formwork to existing structures or creating additional support, formwork brackets help maintain desired shape and stability during concrete pouring. 5. Enabling sharp corners and angles in the formwork, formwork corners ensure accurate concrete pouring and shape preservation. 6. Maintaining proper spacing between formwork panels, formwork spacers ensure even and uniform concrete pouring for a smooth finish. 7. Preventing concrete from sticking to steel panels, formwork release agents are applied to the formwork surface for easy removal after concrete curing. 8. Ensuring level and proper alignment of the formwork, formwork leveling devices contribute to a consistent and uniform concrete finish. In summary, these essential accessories and attachments are pivotal in successfully implementing steel formwork systems. They improve structural integrity, enhance efficiency, and guarantee high-quality finishes for constructed concrete structures.

- Q: Is steel formwork more expensive than other types of formwork?

- The cost of steel formwork depends on various factors such as the size and complexity of the project, availability of materials, labor costs, and market conditions. Generally speaking, steel formwork tends to be more expensive than other types of formwork such as wood or aluminum. Steel formwork offers several advantages over other types of formwork, such as high durability, reusability, and the ability to support heavy loads. However, these benefits come at a higher price. Steel formwork requires a higher initial investment due to the cost of materials and the need for skilled labor for fabrication and installation. On the other hand, wood or aluminum formwork may be less expensive initially, but they may not be as durable or have the same load-bearing capacity as steel formwork. They might require frequent repairs or replacements, which can add to the overall cost in the long run. Ultimately, the choice of formwork material depends on the specific requirements of the project, budget constraints, and the expected number of uses. While steel formwork may be more expensive upfront, it often provides a better return on investment due to its durability and reusability.

- Q: I would like to ask the bridge column (D110) steel template thickness should be how much

- Because of the complexity of bridge construction, in addition to the requirements of key templates of high rigidity, high strength, but also the overall requirements of steel formwork has strong adaptability, to meet the different needs of bridge construction, and the steel plate must have strong compatibility or accommodation. The cross section of the pier column steel formwork is round, round, conical, hyperbolic, etc.,

- Q: What is the maximum concrete pressure that steel formwork can withstand?

- The maximum concrete pressure that steel formwork can withstand varies depending on several factors, including the specific design and construction of the formwork system. However, in general, steel formwork is capable of withstanding higher concrete pressures compared to other types of formwork materials. The maximum concrete pressure that steel formwork can withstand typically ranges from 50 to 100 kilonewtons per square meter (kN/m²) or 7.2 to 14.4 pounds per square inch (psi). This level of pressure is well-suited for a wide range of construction projects, including high-rise buildings, bridges, and other structures that require heavy concrete pours. It is important to note that the maximum concrete pressure that steel formwork can withstand should always be determined by a qualified engineer or designer. They will consider factors such as the height and thickness of the concrete pour, the spacing and size of the formwork supports, and the strength and stability of the steel formwork system. By adhering to the recommended maximum concrete pressure limits, construction professionals can ensure the safety and integrity of the formwork system, minimize the risk of failure or collapse, and achieve a successful concrete pour.

- Q: Can steel formwork be used for architectural concrete slabs?

- Yes, steel formwork can be used for architectural concrete slabs. Steel formwork offers durability, strength, and stability, making it suitable for creating complex architectural designs in concrete slabs. It can provide a smooth finish, precise dimensions, and reusable components for efficient construction.

- Q: How is steel formwork manufactured?

- Steel formwork is manufactured through a series of processes that involve shaping and assembling steel components into the desired formwork structure. The manufacturing process typically begins with the selection of high-quality steel, which is then cut and shaped into various components such as panels, beams, and connectors. One of the key steps in steel formwork manufacturing is the fabrication of panels. This involves cutting steel sheets to the required size and shape using specialized cutting tools such as shears or plasma cutters. These panels are then further processed to create the necessary openings or holes for connectors and accessories. Once the panels are ready, they are assembled together using connectors and fasteners. This assembly process may involve welding, bolting, or riveting, depending on the specific design and requirements of the formwork. The connections are carefully made to ensure the strength and stability of the steel formwork structure. In addition to panels, steel formwork also includes beams and other support components. These are fabricated separately and then integrated into the formwork system during the assembly process. Beams are typically designed to bear heavy loads and provide additional stability to the formwork structure. After the assembly is complete, the steel formwork undergoes a quality inspection to ensure that it meets the required standards and specifications. This inspection involves checking for any defects, such as cracks or deformations, as well as verifying the accuracy of dimensions and connections. Once the steel formwork passes the quality inspection, it is usually surface-treated to enhance its durability and resistance to corrosion. This treatment can involve techniques such as galvanizing or painting, which create a protective layer on the steel surface. Overall, the manufacturing process of steel formwork involves precision cutting, shaping, and assembling of steel components to create a robust and reliable system for concrete construction. The use of high-quality materials and careful attention to detail ensures that steel formwork meets the demands of various construction projects, providing a strong and reusable solution for concrete formwork requirements.

- Q: Can steel formwork be easily modified or adjusted during concrete placement?

- Yes, steel formwork can be easily modified or adjusted during concrete placement. Steel is a highly flexible material that can be easily cut, welded, or reshaped to accommodate changes in design or dimensions. This allows for on-site adjustments to be made during the concrete placement process, ensuring a precise fit and desired form.

- Q: Can steel formwork be used for earthquake-resistant concrete buildings?

- Indeed, earthquake-resistant concrete buildings can utilize steel formwork. Steel formwork pertains to a temporary structure employed to support and shape the concrete until it solidifies and becomes firm. It is renowned for its robustness, longevity, and capacity to endure substantial loads, which are desirable traits in earthquake-resistant construction. During seismic events, buildings endure lateral forces and vibrations. Given its strength and rigidity, steel formwork aids in distributing and transferring these forces across the entirety of the structure. It furnishes the necessary support to guarantee that the concrete walls, columns, and slabs remain intact amidst seismic occurrences. Moreover, steel formwork allows for precision and accuracy throughout the construction process. This is pivotal in earthquake-resistant buildings as any deviation from the intended design can undermine the structure's ability to withstand seismic forces. The utilization of steel formwork assures that the concrete components are adequately reinforced with steel bars and that all essential connections and joints are correctly positioned. Furthermore, steel formwork can be easily assembled, disassembled, and reused, rendering it a cost-effective solution for earthquake-resistant construction endeavors. This facilitates efficient construction practices, diminishes waste, and permits the formwork to serve multiple projects, thereby making it an environmentally friendly choice. Nonetheless, it is crucial to acknowledge that while steel formwork plays a crucial role in earthquake-resistant concrete buildings, it is not the sole determinant of the overall structural integrity. Other design considerations, including proper reinforcement detailing, sufficient foundation design, and appropriate structural analysis, hold equal importance. To conclude, steel formwork can be effectively employed in earthquake-resistant concrete buildings due to its strength, durability, and ability to withstand seismic forces. However, it must be accompanied by proper design and construction practices to ensure the overall structural resilience and safety of the building.

- Q: How does steel formwork handle different concrete water-cement ratio specifications?

- Steel formwork is highly adaptable and can easily handle different concrete water-cement ratio specifications. The strength and durability of steel allow it to withstand the pressures exerted by varying water-cement ratios during the concrete pouring process. Additionally, steel formwork provides a smooth and even surface, ensuring proper consolidation of the concrete, regardless of the water-cement ratio used.

- Q: How does steel formwork contribute to easier formwork removal?

- Steel formwork offers several advantages that contribute to easier formwork removal. Firstly, its high strength and durability enable it to withstand the pressure and weight of the concrete without deforming or warping. As a result, the formwork remains undamaged and intact after the concrete is poured and cured. Secondly, the smooth surfaces of steel formwork facilitate the easy release of the cured concrete. The absence of sticking between the concrete and the formwork simplifies the removal process, especially when dealing with complex shapes and intricate designs. Consequently, the formwork can be removed effortlessly without causing any harm to the concrete. Moreover, steel formwork often incorporates detachable parts or panels, allowing for convenient assembly and disassembly. This feature not only speeds up the removal process but also simplifies the cleaning and maintenance of the formwork. Consequently, the formwork remains in good condition, ensuring its longevity and reusability. Additionally, steel formwork exhibits remarkable resistance to moisture and chemicals commonly encountered in the construction environment. This resistance prevents the formwork from deteriorating or weakening over time. Consequently, the formwork remains intact and in excellent condition, making it easier to remove after the concrete has set. In summary, the strength, durability, smooth surfaces, detachable parts, and resistance to moisture and chemicals make steel formwork an ideal choice for easier formwork removal. This not only simplifies the process but also guarantees the quality and integrity of the concrete structure being constructed.

Send your message to us

Steel Formwork for Skyspare Export to Indonesia

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords