Gas Shielded Welding Wire 1.2mm with MSDS, CE, SGS, ISO9001

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

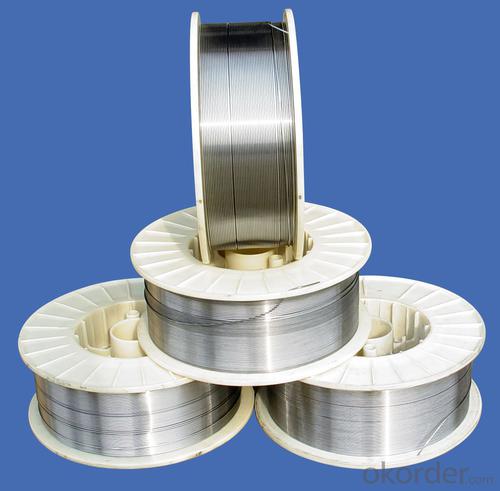

Gas Shielded Welding Wire 1.2mm With MSDS, CE, SGS, ISO9001

Structure of Gas Sheilded Welding Wire

1.ISO,SGS,CE approved

2.free sample, prompt delivery, global customers

3.Shield gas : CO2

4.Material:Carbon steel

5.Package:15kgs-20kgs/spool, 100kg-250kgs/barrel

6.Application:Current range (A) 0.8mm 40-140

7.Lead time:20-30 days after receiving L/C or Pre-paid

Main Features of Gas Sheilded Welding Wire

1. Type: CO2 wire/SG2 welding wire/ Mig wire/ Copper coated welding wire/Solid welding wire/ Gas shielded welding wire

2. Raw material: MIld steel/ Carbon steel

3. Surface--- Copper coated

4. Application : Co2 shielded welding, welding of mild steel material,

5.Diameter:0.8mm-1.6mm

6.Flux content: without flux

Datas Information of Sheilded Welding Wire

Welding wire chemical compositions % :

Mark | Confirm with | Chemical composition, % | |||||||||

ER50-6 |

AWS ER70S-6 | C | Mn | Si | P | S | Ni | Cr | Cu | Mo | V |

0.08 | 1.51 | 0.89 | 0.015 | 0.013 | 0.016 | 0.021 | 0.18 | 0.006 | 0.003 | ||

Mechanical properties of weld metal | Normative |

Tensile strength, MPa | 545 |

Yield strength, MPa | 452 |

Elongation ratio, % | 29 |

Impact toughness, J | 91(-30°C) |

FAQ of Gas Sheilded Welding Wire

Q: How about the quality about your products?

A:We are manufacturer strictly according to national and international standard, and we take a test on every pipe before delivered out. If you want to see our quality certifications and all kinds of testing report, please just ask us for it.

Pictures:

- Q: Can stainless steel wire be used for aircraft components?

- Yes, stainless steel wire can be used for aircraft components. Stainless steel is widely used in the aerospace industry due to its high strength, corrosion resistance, and durability. It is commonly used for various applications such as wiring, cables, fasteners, and structural components in aircraft manufacturing.

- Q: Is stainless steel wire suitable for wire rope tensioners?

- Yes, stainless steel wire is suitable for wire rope tensioners. Stainless steel is known for its high strength and durability, making it an ideal material for applications that require tensioning and securing of wire ropes. It has excellent resistance to corrosion, which is crucial in environments where the tensioner may be exposed to moisture or harsh weather conditions. Stainless steel wire also offers good flexibility and can withstand heavy loads, making it a reliable choice for wire rope tensioners.

- Q: Why does the 304 stainless steel wire produce magnetism when it is stretched?

- As a result of the above reasons, the amount of magnetism is large and small with the amount of deformationThe best and most thorough way to eliminate or reduce the magnetism is to anneal!

- Q: What's the difference between stainless steel tube polishing and stainless steel wire drawing?

- Polishing machine is equipped with polishing wheel. When polishing, polishing wheel rotation speed steel surface and the polishing wheel friction heat pipe to improve the plasticity, polishing force, surface plastic deformation, the convex part is down, and flow to the concave, the surface roughness decreases. In addition, the chemical composition of the polishing tube and the polishing medium are chemically reacted with the polished metal during the polishing process, so that the polishing effect is greatly enhanced.

- Q: How are stainless steel wire brushes used for cleaning?

- Due to their durability and effectiveness, stainless steel wire brushes are commonly used for cleaning in a variety of applications. The bristles of these brushes are made from stainless steel, which is known for its ability to resist corrosion and withstand high temperatures. When using a stainless steel wire brush for cleaning, it is important to take into account the surface being cleaned and the type of dirt or debris that needs to be removed. These brushes are versatile and can be used on various materials such as metal, concrete, and wood. To effectively use a stainless steel wire brush for cleaning, one must first ensure that the brush is in good condition, with no loose or damaged bristles. The brush should be firmly held and applied with moderate pressure, depending on the surface being cleaned. It is crucial to maintain an appropriate angle and move the brush consistently and in a controlled manner. Stainless steel wire brushes are particularly efficient at eliminating rust, paint, and other stubborn substances. The rigid bristles are capable of scraping away these contaminants and providing a thorough cleaning. They are also useful for preparing surfaces before painting or coating, as they help create a clean and smooth surface. Moreover, stainless steel wire brushes are commonly utilized in industrial settings to remove weld scale, slag, and other residues from metal surfaces. They are also employed in automotive applications to clean engine parts, eliminate rust from car bodies, and prepare surfaces for painting. It is important to note that when using stainless steel wire brushes for cleaning, proper safety precautions should be taken. This includes wearing protective eyewear and gloves to prevent potential injuries from flying debris or sharp bristles. It is also essential to adhere to any specific instructions or guidelines provided by the manufacturer for optimal results. In conclusion, stainless steel wire brushes are a versatile and durable tool for cleaning various surfaces. Their rigid bristles and corrosion-resistant properties make them effective at removing rust, paint, and other stubborn substances. By following proper techniques and safety precautions, these brushes can facilitate a thorough and efficient cleaning process.

- Q: What are the different types of stainless steel wire springs used in the furniture industry?

- The furniture industry commonly employs various kinds of stainless steel wire springs to enhance support and functionality in different furniture pieces. Some of the stainless steel wire springs used in this industry include: 1. Coil Springs: These springs, which are widely utilized in furniture manufacturing, involve coiling stainless steel wire into a helical shape. They offer exceptional durability and support, making them suitable for a wide range of furniture applications. 2. Sinuous Springs: Also known as zigzag or serpentine springs, sinuous springs consist of a series of S-shaped wires fastened to the furniture frame. They are often employed in seating furniture, such as sofas and chairs, to provide a comfortable and supportive foundation. 3. Tension Springs: Referred to as extension springs as well, tension springs find typical use in recliners or furniture with adjustable features. These springs function by stretching or extending when force is applied and then returning to their original position upon release of the force. 4. Pocket Springs: Pocket springs, also known as encased or wrapped springs, consist of individually wrapped coil springs placed in fabric pockets. These springs are commonly found in high-end furniture pieces like mattresses and upholstered chairs, offering exceptional comfort and support. 5. Bonnell Springs: Hourglass-shaped coil springs, also called Bonnell springs, are large and interconnected. They are commonly employed in upholstered furniture like sofas and mattresses to provide consistent support and durability. 6. Torsion Springs: Torsion springs are generally used in furniture mechanisms that require rotational force or tension. They operate by exerting torque when twisted or rotated, making them suitable for applications like reclining chairs or adjustable headrests. Each type of stainless steel wire spring possesses unique characteristics and advantages, and the selection of the spring type depends on the specific requirements of the furniture piece and the desired level of comfort and support.

- Q: Can stainless steel screws be operated by an automatic lock screw machine?

- The automatic lock screw machine has no special requirement for the material of the screw, and the general screw or the stainless steel screw can be used.

- Q: Can stainless steel wire be used for wire rope clips?

- Certainly! Wire rope clips can make use of stainless steel wire. Stainless steel, being highly durable and resistant to corrosion, is ideal for a range of purposes, including wire rope clips. These clips serve the purpose of fastening wire rope ends and preventing them from unwinding or slipping. By opting for stainless steel wire rope clips, one can guarantee a robust and secure connection, while also benefiting from the anti-corrosion characteristics of stainless steel. This makes them particularly well-suited for outdoor or marine settings.

- Q: How to make clothes hanger for 4 mm 304 stainless steel wire

- Stainless steel is a metallic material, stainless steel (Stainless, Steel) refers to air, steam, water and other weak corrosive medium and acid, alkali, salt and other chemical corrosive medium corrosion of steelAlso called stainless acid resistant steel

- Q: What are the different wire sizes available for stainless steel wire?

- Stainless steel wire comes in different sizes, classified by their diameter. The usual sizes vary from 0.025mm (0.001 inches) to 6.35mm (0.25 inches). These sizes are commonly represented by a gauge number, with higher numbers indicating thinner wires. For instance, a 24-gauge wire is thinner than a 16-gauge wire. Nevertheless, it is worth mentioning that wire sizes may slightly differ depending on the manufacturer or specific application needs.

Send your message to us

Gas Shielded Welding Wire 1.2mm with MSDS, CE, SGS, ISO9001

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords