Galvanized welded steel pipe for any materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1、Structure of Galvanized welded steel pipe for materials :

The surface of galvanized steel pipe welded steel pipe of hot dip galvanized layer or. Galvanized can increase the corrosion resistance of the steel tube, prolong service life. Galvanized pipe is widely used, in addition to water, gas, oil and other general low pressure fluid pipelines. It is also used in the petroleum industry, especially for offshore oil field of oil well pipe and oil pipe, chemical, coking equipment of oil heater, condensation cooler, coal run oil exchanger tube, and trestle pile, the mine tunnel support frame tube.

2、Main Features of Galvanized welded steel pipe for building materials :

• High manufacturing accuracy

• High strength

• Good visual effect

• Reasonable price

3、 Galvanized welded steel pipe for building materials Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 1 - 33 mm |

Section Shape | Round |

Outer Diameter | 21 - 610mm |

Place of Origin | Tianjin, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:Q195 Q235 Q345 X42 X52

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Galvanized welded steel pipe for building materials :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

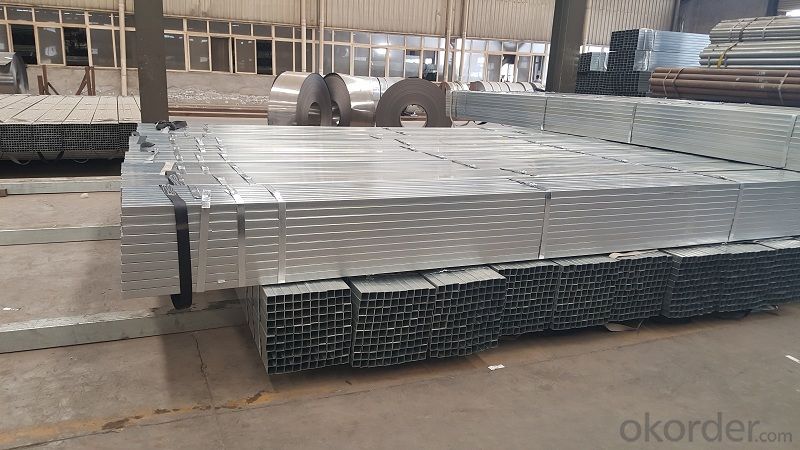

6、 Galvanized welded steel pipe for building materials Images:

- Q: What is the difference between internal coating and external lining of steel pipes?

- Steel pipes can be protected from corrosion and damage through two different methods: internal coating and external lining. When it comes to internal coating, a protective layer or coating is applied to the inner surface of the steel pipe. This is done to prevent corrosion or damage caused by the fluid or substance being transported through the pipe. Common materials used for the coating include epoxy, polyurethane, or polyethylene. These materials create a barrier between the pipe and the transported material, thus extending the pipe's lifespan and preserving the quality of the transported material. On the other hand, external lining involves applying a protective layer or lining to the outer surface of the steel pipe. The purpose of this is to shield the pipe from external elements like soil, moisture, chemicals, and physical damage. Materials such as polyethylene, polypropylene, or fusion-bonded epoxy are typically used for the external lining. By acting as a barrier, the lining prevents corrosive substances from coming into contact with the pipe and causing harm. Additionally, it helps maintain the pipe's structural integrity and prevents the formation of leaks or cracks. To summarize, the main distinction between internal coating and external lining of steel pipes lies in where the protective layer is applied. Internal coating focuses on the inner surface of the pipe, while external lining concentrates on the outer surface. While both methods aim to safeguard the pipe from corrosion and damage, they address different aspects of pipe protection.

- Q: What is the difference between the stainless steel pipe welded pipe and seamless pipe?

- Welding performance: chemical composition of seamed pipe and seamless pipe are different. The production of seamless steel components only meets the basic requirements of astm. The production of seamed tube steel containing suitable for chemical composition of welding. For example, the mixing of silicon, sulfur, manganese, oxygen, and a certain proportion of elements such as the triangle ferrite can produce a welding flux which is easy to transfer heat during welding, so as to make the whole weld be welded well. The lack of steel pipe above the chemical components, such as seamless tube, can produce all kinds of unstable factors in the process of welding, welding and welding penetration is not easy.

- Q: Can steel pipes be used for oil wells?

- Yes, steel pipes can be used for oil wells. Steel pipes are highly durable and resistant to corrosion, making them suitable for the harsh conditions and high-pressure environments encountered in oil drilling operations.

- Q: Can steel pipes be used for geothermal applications?

- Yes, steel pipes can be used for geothermal applications. Steel pipes have high strength and durability, which makes them suitable for handling the high temperatures and pressures involved in geothermal systems. Additionally, steel pipes are resistant to corrosion and can withstand the harsh conditions found deep underground, making them a reliable choice for transporting geothermal fluids.

- Q: Are steel pipes suitable for pharmaceutical manufacturing facilities?

- Indeed, steel pipes prove to be a fitting option for pharmaceutical manufacturing facilities. Their outstanding resistance to corrosion and durability make them a prevalent choice in this industry. They are capable of enduring high levels of pressure and temperature, rendering them perfect for a wide range of purposes, including fluid, gas, and chemical transportation within the facility. Moreover, steel pipes possess the advantage of effortless cleaning and sanitization, guaranteeing the preservation and safety of pharmaceutical products. Additionally, they offer cost-effectiveness and boast an extended lifespan, solidifying their status as a dependable choice for pharmaceutical manufacturing facilities.

- Q: What are the different standards and specifications for steel pipes?

- There are several different standards and specifications for steel pipes, including ASTM (American Society for Testing and Materials), API (American Petroleum Institute), and ANSI (American National Standards Institute). These standards outline the requirements for various aspects of steel pipes such as dimensions, material composition, mechanical properties, and testing methods. Additionally, there are specific standards for different applications, such as oil and gas pipelines, structural pipes, and water supply systems, which further define the specifications and performance criteria for steel pipes.

- Q: What are the different wall thicknesses available for steel pipes?

- The different wall thicknesses available for steel pipes vary depending on the specific application and requirements. Common wall thicknesses for steel pipes include standard, extra strong, and double extra strong, with each thickness offering different levels of strength and durability.

- Q: How are steel pipes specified in engineering drawings?

- Steel pipes are specified in engineering drawings by providing information such as the diameter, length, wall thickness, material grade, and any other relevant specifications or standards that need to be followed.

- Q: How are steel pipes coated for underground applications?

- Steel pipes are typically coated for underground applications using a process known as external coating or corrosion protection. This involves applying a layer of protective material, such as epoxy or polyethylene, onto the surface of the steel pipe. The coating acts as a barrier, preventing the pipe from coming into contact with moisture, soil, and other corrosive elements that could lead to degradation over time. Additionally, before applying the coating, the steel pipes are often cleaned and prepared through processes like sandblasting or shot blasting to remove any impurities and create a smooth surface for better adhesion of the protective coating.

- Q: How are steel pipes used in the construction of sewer systems?

- Steel pipes are commonly used in the construction of sewer systems due to their durability and strength. These pipes are used to transport sewage and wastewater from households and businesses to treatment plants or disposal sites. They are resistant to corrosion and can withstand high pressure, making them ideal for underground installations. Additionally, steel pipes can be manufactured in various sizes and lengths, allowing for efficient and cost-effective installation in sewer infrastructure.

Send your message to us

Galvanized welded steel pipe for any materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords