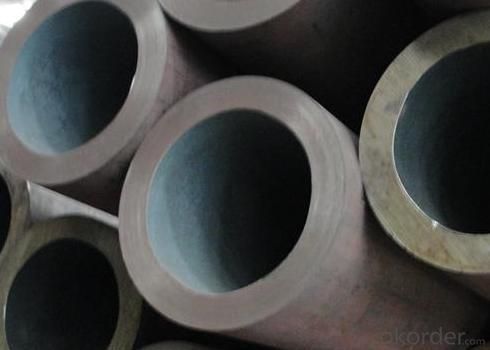

High Quality Seamless Steel Tubes For High-pressure For Chemical Fertilizer Equipments

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality Seamless Steel Tubes For High-pressure For Chemical Fertilizer Equipments

1) Superior in quality

2) Quick in delivery

3) OD: 8-720mm WT:3-60mm

4) Material: 10# 20#,304 Q235 Q235B

Size OD: 3-60mm

WT: 8-720MM

Standard: GB/T8162 GB3087 BGZJ518-2006 GB/T8163

Grade : 20#,304 Q235 Q235B Q235C Q235D and so on

End : BE and Plain end with pipe caps

Technique :Cold rolled, hot rolled, cold drawn

Usage: Used for industrial pipe, high-pressure boiler pipe, and food industry

Payment: TT and irrevocable L/C

Packaging of High Quality Seamless Steel Tubes For High-pressure For Chemical Fertilizer Equipments:

Wrapped in bundles with steel strips or according to customers' requirements

- Q: What is the theoretical weight per square meter of the steel pipe diameter of the outer frame and the thickness of the tube wall 3mm 48mm?

- Formula: outside diameter - wall thickness * wall thickness *0.02466=, weight per meter! : 48-3*3*0.02466=3.3291

- Q: How are steel pipes protected against electrolytic corrosion?

- Various methods can be employed to safeguard steel pipes against electrolytic corrosion. One commonly utilized approach involves the application of protective coatings on the pipe's surface. These coatings serve as a barrier, effectively preventing direct contact between the steel and the surrounding environment, which may contain moisture and other corrosive substances. Epoxy, polyethylene, and zinc are frequently employed coatings for this purpose. Another means of protection involves the utilization of sacrificial anodes. These anodes, typically fabricated from a metal that exhibits greater reactivity than steel, such as zinc or aluminum, are affixed to the steel pipes. Over time, as these anodes corrode, they willingly sacrifice themselves in order to shield the steel. This process, known as cathodic protection, is exceptionally successful in deterring electrolytic corrosion. Aside from coatings and sacrificial anodes, proper insulation and electrical isolation play a pivotal role in preventing electrolytic corrosion of steel pipes. Insulating materials, such as rubber or plastic sleeves, are employed to prevent direct contact between the pipes and other metals or electrolytes. Electrical isolation can be achieved through the use of dielectric unions or insulating flanges, which effectively obstruct the flow of electric current between different sections of the pipeline. Furthermore, regular maintenance and inspection are essential components of protecting steel pipes against electrolytic corrosion. Regular checks to assess coating integrity, anode condition, and potential electrical leakage are crucial in maintaining the ongoing efficacy of the corrosion protection system. In conclusion, a combination of protective coatings, sacrificial anodes, insulation, electrical isolation, and regular maintenance is indispensable in safeguarding steel pipes against electrolytic corrosion. By implementing these measures, the lifespan of steel pipes can be substantially prolonged, thereby ensuring the safety and reliability of various applications, including water distribution, oil and gas transportation, and structural support in buildings and infrastructure.

- Q: How do you calculate the pipe volume for steel pipes?

- In order to determine the volume of a steel pipe, one must possess knowledge regarding its length and the inner diameter. The formula for calculating the volume of a cylindrical shape, such as a pipe, is V = πr^2h, where V denotes the volume, π represents a mathematical constant which is approximately equivalent to 3.14159, r signifies the radius of the pipe (which is half of the inner diameter), and h stands for the length of the pipe. Initially, employ a measuring tape or a caliper to measure the inner diameter of the pipe. Proceed to divide this value by 2 in order to obtain the radius. Afterwards, proceed to measure the length of the pipe, utilizing inches, feet, or meters. Ensure that the same unit of measurement is used for both the radius and length. Once the measurements for the radius and length have been ascertained, input them into the formula V = πr^2h. For instance, let us assume that the inner diameter of the steel pipe measures 10 inches and the length amounts to 50 feet. Firstly, divide the inner diameter by 2 to determine the radius: 10 / 2 = 5 inches. Next, convert the length into inches: 50 feet * 12 inches/foot = 600 inches. Subsequently, input the values into the formula: V = 3.14159 * 5^2 * 600. By calculating the volume: V = 3.14159 * 25 * 600 = 47,123.85 cubic inches. Therefore, the volume of the steel pipe is approximately 47,123.85 cubic inches.

- Q: How are steel pipes used in the manufacturing of aerospace components?

- Steel pipes are used in the manufacturing of aerospace components as they provide structural support and durability. They are commonly used for fuel and hydraulic systems, allowing for the safe and efficient transfer of fluids throughout the aircraft. Additionally, steel pipes are utilized in the fabrication of engine components and airframe structures, ensuring strength and reliability in the demanding aerospace environment.

- Q: What is the weight and strength of steel pipes?

- Steel pipes can vary in weight and strength depending on their dimensions and the specific grade of steel used. The weight of steel pipes is typically measured in pounds per foot or kilograms per meter. The strength of steel pipes is commonly measured in terms of its yield strength and ultimate tensile strength. The weight of steel pipes can range from a few pounds per foot for smaller sizes to several hundred pounds per foot for larger diameters and thicker walls. The weight is influenced by factors such as the pipe's outer diameter, wall thickness, and length. For example, a 1-inch diameter steel pipe with a wall thickness of 0.125 inches may weigh around 0.67 pounds per foot, while a 12-inch diameter steel pipe with a wall thickness of 0.5 inches can weigh around 142 pounds per foot. The strength of steel pipes is determined by the grade of steel used, which can vary depending on the application and specific requirements. Common grades of steel used for pipes include ASTM A53 for general-purpose applications, ASTM A106 for high-temperature service, and API 5L for oil and gas transportation. These grades have different yield strengths and ultimate tensile strengths. Yield strength refers to the amount of stress a steel pipe can withstand before it begins to deform plastically. It is usually measured in pounds per square inch (psi) or megapascals (MPa). For example, ASTM A53 Grade B steel pipe has a minimum yield strength of 35,000 psi (240 MPa), while API 5L Grade X65 steel pipe has a minimum yield strength of 65,000 psi (448 MPa). Ultimate tensile strength, on the other hand, is the maximum stress a steel pipe can withstand before it fractures. It is also measured in psi or MPa. For instance, ASTM A106 Grade B steel pipe has an ultimate tensile strength of 60,000 psi (415 MPa), whereas API 5L Grade X65 steel pipe has an ultimate tensile strength of 77,000 psi (531 MPa). In summary, the weight and strength of steel pipes can vary depending on their dimensions and the grade of steel used. The weight is influenced by factors such as the pipe's diameter, wall thickness, and length, while the strength is determined by the steel's yield strength and ultimate tensile strength.

- Q: What are the different methods of joining steel pipes for high-pressure applications?

- Some of the different methods of joining steel pipes for high-pressure applications include welding, threaded connections, flanged connections, and mechanical couplings. Welding involves fusing the pipes together using heat, making it a strong and permanent connection. Threaded connections involve screwing the pipes together using threads on the ends, which can be easily assembled and disassembled. Flanged connections involve using flanges and bolts to connect the pipes, providing a secure and leak-proof connection. Mechanical couplings use mechanical devices such as clamps or compression fittings to join the pipes, allowing for quick and easy installation and removal.

- Q: What are the different methods of pipe bending for steel pipes?

- There exists a variety of methods for bending steel pipes, each possessing its own advantages and limitations. 1. Manual Pipe Bending: The bending of steel pipes is achieved through the utilization of hand tools or a manual pipe bender. This method is best suited for small-scale projects or situations where only a few bends are necessary. However, it demands skill and precision to ensure accurate and consistent bends. 2. Rotary Draw Bending: This method involves the utilization of a mandrel, clamp die, and a bending die to bend the pipe around a stationary bend die. The mandrel serves to preserve the shape of the pipe and prevent wrinkling or collapsing during the bending process. Rotary draw bending is commonly employed to produce tight-radius bends with high accuracy and repeatability. 3. Induction Pipe Bending: In this method, a specific area of the steel pipe is heated using an induction coil, rendering it more malleable for bending. Once the desired temperature is attained, hydraulic or mechanical force is applied to bend the pipe. Induction bending is suitable for large-diameter pipes or situations requiring multiple bends in a single pipe. 4. Roll Bending: Also referred to as pyramid rolling, this method involves passing the steel pipe through three adjustable rolls that gradually shape the pipe into the desired form. Roll bending is suitable for generating large-radius bends and is frequently employed in the construction of spiral staircases, handrails, and structural applications. 5. Hot Bending: This method necessitates heating the steel pipe to elevated temperatures, typically accomplished using a furnace, in order to facilitate bending. Hot bending permits greater flexibility in shaping the pipe and is commonly used for large-diameter or thick-walled pipes. However, it demands specialized equipment and expertise to control the temperature and prevent distortion or damage to the pipe. When selecting the appropriate method of pipe bending for steel pipes, it is crucial to take into account factors such as the required bend radius, pipe diameter, wall thickness, and project specifications. Seeking the advice of an experienced pipe bending professional or engineer can assist in determining the most suitable method for a specific application.

- Q: Can steel pipes be used for irrigation systems?

- Yes, steel pipes can be used for irrigation systems. They are strong, durable, and resistant to corrosion, making them suitable for transporting water and withstanding outdoor conditions. However, it is important to ensure proper insulation and maintenance to prevent any potential rust or degradation.

- Q: How are steel pipes used in the agriculture industry?

- Steel pipes are used in the agriculture industry for various purposes such as irrigation systems, drainage systems, and livestock handling equipment. They provide a durable and reliable solution for transporting water, nutrients, and effluents, ensuring efficient and effective operations in farm settings.

- Q: What are the advantages of using stainless steel pipes?

- There are several advantages of using stainless steel pipes. Firstly, stainless steel pipes have excellent corrosion resistance, making them suitable for various industries, including water supply, chemical processing, and oil and gas. Secondly, they have high strength and durability, allowing them to withstand extreme temperatures and pressure. Additionally, stainless steel pipes are hygienic and easy to clean, making them ideal for applications in the food and beverage industry. Lastly, they have a long lifespan and require minimal maintenance, resulting in cost savings in the long run.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2001 |

| Annual Output Value | 800,000Tons |

| Main Markets | Europe and the United States; Canada; India; South etc. |

| Company Certifications | API 5L; API 5CT; GB/T19001-2000 idt ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Lianyungang |

| Export Percentage | 50% - 60% |

| No.of Employees in Trade Department | 1000-1100 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 423,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Seamless Steel Tubes For High-pressure For Chemical Fertilizer Equipments

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords