Galvanized steel sheet Z80

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

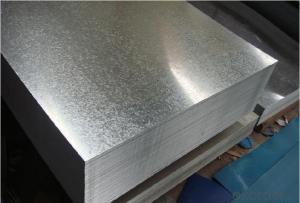

| Grade: | galvanized sheet,DX51D+Z SGCC CSB S280GD+Z S350GD+Z | Standard: | JIS,AISI,ASTM,GB,DIN,EN,JIS,AISI,ASTM,GB,DIN | Length: | 500mm-12000mm,1000~6000mm |

| Thickness: | 0.1mm-100mm | Width: | 600mm-2000mm | Place of Origin: | Jiangsu China (Mainland) |

| Brand Name: | DX51D+Z SGCC CSB S280GD+Z S350GD+Z | Model Number: | galvanized sheet,ASTM A653, ASTMA526-90, JIS G3302, DIN EN10142-92, GB/T 2518 | Type: | Plate |

| Application: | indurstry;electricity construction,home appliances,kitchen appliance, mechanical etc | Certification: | SGS | Surface: | Galvanized |

| Technique: | Cold Rolled | Special Use: | High-strength Steel Plate | Delivery Time: | 3-15 days |

| Delivery Term: | TT or LC |

Packaging & Delivery

| Packaging Detail: | Export standard package :bundled wooden box or be required; The inner size of container is below: 20 ft GP:5.8m(length)x 2.13m(width)x 2.18m(high) about 24-26 CBM 40 ft GP:11.8m(length)x 2.13m(width)x 2.72m(high)about 68 CBM We will packing as the factory ,and reach the stander of export . Or as the customer request.In addition,We will make the products with good surface protection |

| Delivery Detail: | within 3--15 days according to the Quantity |

Specifications

China supplier Galvanized Steel Sheet

1:thick:0.25-6mm

2:width:500-1500mm

3:length:any length can be cut

4:on stock

- Q: Can steel sheets be used for kitchen appliances?

- Yes, steel sheets can be used for kitchen appliances. Steel is a popular material choice for kitchen appliances due to its durability, strength, and resistance to corrosion. It is commonly used in the manufacturing of refrigerators, ovens, dishwashers, and other kitchen appliances. Steel sheets can be easily molded and fabricated into various shapes and sizes, making them suitable for different appliance designs. Additionally, steel is easy to clean, making it hygienic and ideal for kitchen environments.

- Q: What is the process of polishing steel sheets?

- The process of polishing steel sheets involves several steps to achieve a smooth and shiny finish. First, the steel sheets are cleaned to remove any dirt, oil, or debris that may be present on the surface. This is typically done using a degreaser or a solvent. Next, the sheets are sanded using abrasive materials, such as sandpaper or a sanding belt. This step helps to remove any visible scratches or imperfections on the surface of the steel. After sanding, the sheets are typically polished using a polishing compound or paste. This compound is applied to the surface and rubbed in with a cloth or a buffing wheel. The polishing compound helps to remove any remaining scratches and brings out the natural shine of the steel. Once the initial polishing is complete, a finer polishing compound may be used to further enhance the shine and smoothness of the steel sheets. This step is repeated until the desired level of polish is achieved. Finally, the sheets are thoroughly cleaned and inspected to ensure that they meet the desired quality standards. This may involve removing any remaining polishing compound residue and checking for any remaining imperfections. Overall, the process of polishing steel sheets requires careful cleaning, sanding, and polishing to achieve a smooth and shiny finish. The specific techniques and materials used may vary depending on the desired level of polish and the type of steel being polished.

- Q: What are the standard dimensions for steel sheets?

- The standard dimensions for steel sheets vary depending on the specific type and grade of steel, but commonly used dimensions include 4 feet by 8 feet, 4 feet by 10 feet, and 5 feet by 10 feet.

- Q: Can steel sheets be used for toolboxes and cabinets?

- Yes, steel sheets can be used for toolboxes and cabinets. Steel is a durable and sturdy material that can withstand heavy loads and provide excellent protection for tools and items stored inside. It is commonly used in the construction of toolboxes and cabinets due to its strength and ability to resist damage from impact and corrosion.

- Q: Can the steel sheets be used for skylights or roof windows?

- Yes, steel sheets can be used for skylights or roof windows.

- Q: Can steel sheets be bent or formed?

- Yes, steel sheets can be bent or formed due to their malleability and ductility properties.

- Q: What is the difference between a hot rolled and pickled steel sheet?

- A hot rolled steel sheet is made by rolling a heated slab of steel through a series of large rollers, resulting in a thick and rough surface finish. On the other hand, a pickled steel sheet undergoes an additional process called pickling, where the surface of the hot rolled steel is treated with an acid solution to remove impurities and create a smooth and clean surface finish. So, the main difference between the two is the surface finish - hot rolled steel has a rougher surface, while pickled steel has a smoother and cleaner surface.

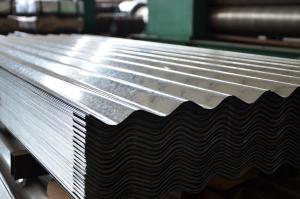

- Q: What are the applications of steel sheets in construction?

- Due to their exceptional strength, durability, and versatility, steel sheets find a wide range of applications in the construction industry. Some of the key uses of steel sheets in construction are: 1. Roofing and cladding: Steel sheets are commonly employed in both residential and commercial buildings for roofing and cladding purposes. They offer a long-lasting and weather-resistant solution, safeguarding the structure against the elements. 2. Structural components: Steel sheets are utilized to construct beams, columns, and trusses, which are essential structural components. The high strength-to-weight ratio of steel enables the creation of lightweight yet robust structures capable of withstanding heavy loads and seismic forces. 3. Flooring: In industrial buildings, warehouses, and factories, steel sheets are often used as flooring material. Their smooth surface facilitates easy cleaning and maintenance, and their strength and fire-resistant properties ensure a safe working environment. 4. Wall partitions: Steel sheets are commonly used in the construction of wall partitions due to their stability and sound insulation properties. They can be easily cut and shaped to fit any design, allowing for flexible and customizable partition layouts. 5. Ductwork and HVAC systems: Steel sheets find extensive use in the fabrication of ductwork and HVAC systems. Their smooth and airtight surfaces enable efficient air movement and regulation, ensuring proper ventilation and temperature control in buildings. 6. Reinforcement: Steel sheets are frequently integrated into concrete structures as reinforcement. This enhances the strength and load-bearing capacity of the building, making it more resistant to bending, tension, and compression forces. 7. Safety and security: Steel sheets are utilized in the construction of safety and security features such as doors, gates, and window frames. Their high strength and resistance to impact and vandalism make them an ideal choice for ensuring the safety and protection of a building. In conclusion, steel sheets play a crucial role in construction for various applications, including roofing, cladding, structural components, flooring, wall partitions, ductwork, reinforcement, and safety features. Their superior strength, durability, and versatility make them an indispensable component in different construction projects, contributing to the overall safety, longevity, and functionality of buildings.

- Q: Can the steel sheets be used for automotive body panels?

- Indeed, automotive body panels can utilize steel sheets. The automotive industry often opts for steel as a material of choice owing to its robustness, resilience, and capacity to withstand impacts. Body panels frequently employ steel sheets because they confer structural integrity to vehicles and effectively safeguard occupants during collisions. Furthermore, steel can be effortlessly shaped and molded into intricate forms, rendering it ideal for designing diverse body panels. All in all, steel sheets are a dependable and frequently preferred option for automotive body panels.

- Q: Can steel sheets be used in food processing industries?

- Yes, steel sheets can be used in food processing industries. Stainless steel sheets are commonly used in food processing industries due to their many beneficial properties. Stainless steel is resistant to corrosion, which is essential in an environment where food is processed, as it prevents contamination and ensures the safety of the final product. Steel sheets are also easy to clean and maintain, making them ideal for use in industries where hygiene is of utmost importance. Additionally, stainless steel is non-reactive to food, meaning it does not leach any harmful chemicals into the processed food. Steel sheets are versatile and can be used for various applications in food processing industries, such as countertops, worktables, shelving, and equipment surfaces.

Send your message to us

Galvanized steel sheet Z80

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords