galvanized steel Z80

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized steel coil

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity | Hot dip galvanized steel coil |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143/ GB/T 2518 |

Grade | DX51D/ S250,280,320GD,SGCC,SGHC,SGH340,SGH400,SGH440,G450,G550 |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 900mm/1000mm/1219mm/1200mm/1220mm/1250mm |

Thickness | 0.2mm~4.0mm |

Type of coating: | galvanized |

Zinc coating | Z40-275g/m2,Z40-Z450g/m2 |

Surface treatment | chromed / skinpass/ oiled/slightly oiled/ dry/ |

Surface structure: | zero spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-10/MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

Application: | home appliances, constructions, building, machineries |

Price terms | FOB,CFR,CIF |

Payment terms | T/T,L/C |

delivery time | 25~40days after deposit or the receipt the L/C |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test |

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Our Production Line:

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of products

Our Application

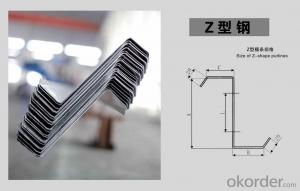

- Q: What are the different types of steel profiles used in architecture?

- There are several types of steel profiles commonly used in architecture, including I-beams, H-beams, C-channels, and angle irons. These profiles are widely utilized in building structures, providing strength and support for various architectural designs.

- Q: What are the different types of steel gratings and walkways available?

- There are several types of steel gratings and walkways available, including welded steel gratings, press-locked steel gratings, and riveted steel gratings. Additionally, there are various options for surface treatments, such as galvanized or painted coatings, to enhance durability and resistance to corrosion. These steel gratings and walkways can be customized in terms of size, shape, and load-bearing capacity to suit specific industrial or architectural requirements.

- Q: How are steel forgings different from castings?

- Steel forgings and castings are two different manufacturing processes used to produce metal components. The main difference lies in the way each process shapes and forms the metal. Forgings involve the application of pressure or force to shape heated metal, resulting in a stronger and more durable product. On the other hand, castings involve pouring molten metal into a mold and allowing it to solidify, resulting in a less dense and more porous product. In summary, forgings offer superior strength and structural integrity, while castings provide more intricate and complex shapes.

- Q: What is the role of steel in the manufacturing of railway tracks?

- Steel plays a crucial role in the manufacturing of railway tracks as it provides the necessary strength, durability, and resilience to withstand the heavy loads and constant wear and tear of trains. It is used to construct the rails, which provide a smooth and stable surface for train wheels to run on. Steel's high tensile strength allows for longer and continuous tracks without the need for frequent expansion joints, ensuring a safer and more efficient railway system.

- Q: How is steel pipe coated for corrosion protection?

- Steel pipe can be coated for corrosion protection using various methods, including applying a layer of zinc through hot-dip galvanizing, using epoxy or polyethylene coatings, or employing a combination of both. These coatings create a barrier between the steel and the surrounding environment, preventing corrosion and extending the lifespan of the pipe.

- Q: How do steel products contribute to the construction of research laboratories and scientific facilities?

- Steel products play a crucial role in the construction of research laboratories and scientific facilities due to their strength, durability, and versatility. Steel is commonly used for framing structures, providing a strong and stable framework for the building. Additionally, steel is used in the fabrication of laboratory equipment, such as benches, cabinets, and storage units, ensuring the durability required for scientific experiments and research activities. Furthermore, steel is resistant to fire, corrosion, and pest infestation, making it a reliable choice for long-term use in these specialized facilities. Overall, steel products contribute to the construction of research laboratories and scientific facilities by providing the necessary structural support and ensuring the durability and safety of the building and its equipment.

- Q: How is steel pipe coated for corrosion resistance?

- Steel pipe can be coated for corrosion resistance through various methods such as galvanization, epoxy coating, or fusion-bonded epoxy coating. Galvanization involves applying a layer of zinc to the steel surface, forming a protective barrier against corrosion. Epoxy coating involves applying a layer of epoxy resin to the pipe surface, providing a durable barrier against corrosion. Fusion-bonded epoxy coating involves applying a powder coating to the heated pipe surface, which then melts and fuses to form a corrosion-resistant layer. These coating methods help protect steel pipes from the damaging effects of corrosion, extending their lifespan and maintaining their structural integrity.

- Q: How is steel profiled and cut?

- Steel is profiled and cut using various methods such as laser cutting, plasma cutting, water jet cutting, and mechanical cutting. Laser cutting involves using a high-powered laser beam to melt or vaporize the steel, resulting in a precise and clean cut. Plasma cutting involves using a plasma torch that generates an electrical arc and a high-velocity jet of ionized gas to cut through the steel. Water jet cutting uses a high-pressure stream of water mixed with abrasive material to cut through the steel. Mechanical cutting methods involve the use of saws, shears, or drills to physically cut and shape the steel. These methods offer different advantages depending on the thickness and type of steel being cut.

- Q: What are the properties and characteristics of stainless steel?

- Stainless steel is a corrosion-resistant alloy that contains a minimum of 10.5% chromium, which forms a passive layer on the surface, preventing further oxidation. It is known for its high strength, durability, and heat resistance, making it suitable for various applications. Stainless steel is also easy to clean, non-magnetic, and has excellent hygiene properties, making it ideal for use in the food and medical industries. It is available in different grades, each with specific properties, such as increased corrosion resistance or improved strength, to suit different applications.

- Q: What are the properties of alloy steel for high-temperature applications?

- Alloy steel for high-temperature applications possesses several properties that make it suitable for such conditions. These properties include excellent strength, resistance to oxidation and corrosion, high thermal stability, and good creep resistance. Alloy steel also exhibits good mechanical properties, such as high tensile strength and toughness, which allow it to withstand the elevated temperatures and stresses experienced in high-temperature environments. Additionally, alloy steel can maintain its structural integrity even at extreme temperatures, making it a reliable choice for applications that involve exposure to heat and harsh conditions.

Send your message to us

galvanized steel Z80

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords