Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

Grade | DX51D, SGCC, CGCC |

Thickness | 0.15mm-1.5mm |

Width | 600mm-1500mm(914/1219/1250 are available) |

Standard | JIS G3312, ASTM,GB/T1275 |

Certificate | ISO9001.ISO14001.OHSAS18001 |

Length | As per requests |

Zinc Coating | 40g-275g/m2 |

Lacquer Coated | 20-25 microns/5-15 microns |

Coil ID | 508mm/610mm |

Coil Weight | normally 3-10mt or as your requirement |

Supply ability | 200,000Mt/year (MOQ:25Mt) |

Color | RAL No. |

Price terms | FOB,CFR,CIF |

Payment terms | L/C,T/T |

Deliver time | 30days after received deposit or L/C |

Packing | Standard exporting package |

steel strip Water proof paper, metal covers, | |

Application | Corrugated roofing,outside building, |

boating building,car producing | |

household appliance | |

Main market | Southeast Asia , the EU, Russia, Ukraine , Latin America and other countries and Regions |

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

Thickness | Width | Length of plate | Inner diameter of coil |

0.18-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass: | |||

Available Coated Mass(g/m^2) | Base plate | Available Coated Mass(g/m^2) | |

60,80, 100, 120, 160, 180 | Galvanized Steel | 60,80, 100, 120, 160, 180 | |

50, 70, 150 | Galvalume Steel | 50, 70, 150 |

Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20±5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface |

|

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coatin | Primer coating + Finish back coating | 2/2 | |

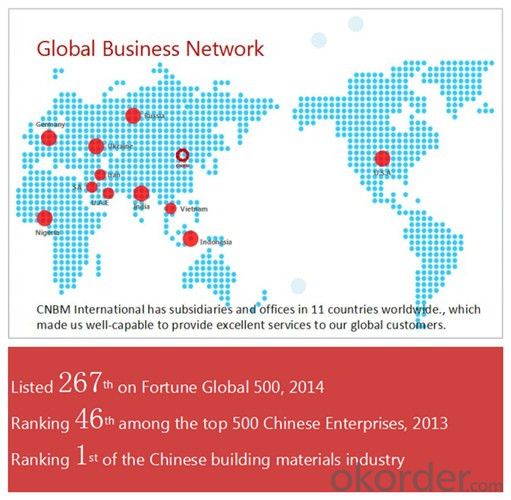

CNBM Introduction of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

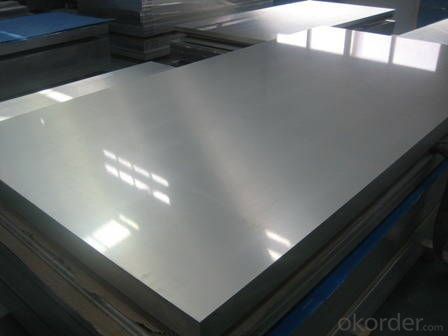

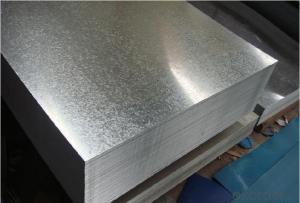

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the properties of carbon steel?

- Carbon steel is a type of steel that primarily consists of iron and carbon, with trace amounts of other elements. It is known for its high strength, durability, and ability to be easily shaped, making it suitable for a wide range of applications. It exhibits excellent hardness and wear resistance, while also being relatively low-cost compared to other types of steel. Carbon steel can be further classified based on its carbon content, with higher carbon levels providing increased hardness and strength. Additionally, it is susceptible to corrosion and requires proper maintenance to prevent rusting.

- Q: How does special steel contribute to the waste management industry?

- Special steel contributes to the waste management industry by providing durable and corrosion-resistant materials for the construction of waste handling equipment and infrastructure. Special steel is used to manufacture waste containers, compactors, shredders, and incinerators, ensuring their longevity and efficiency in handling waste. Additionally, special steel is utilized in the construction of waste treatment plants and landfill facilities, providing structural strength and resistance to harsh environmental conditions. Overall, special steel plays a crucial role in enhancing the effectiveness and sustainability of waste management practices.

- Q: Can special steel be used in the telecommunications industry?

- Yes, special steel can be used in the telecommunications industry. It is often used in the construction of telecommunication towers, antennas, and transmission lines due to its high strength, corrosion resistance, and durability.

- Q: What are the requirements for special steel used in electronic components?

- The requirements for special steel used in electronic components are quite specific and stringent. Firstly, the steel must possess excellent electrical conductivity to ensure effective transmission of electrical signals within the components. This is crucial for maintaining the functionality and performance of electronic devices. Additionally, the steel used in electronic components must have high corrosion resistance to protect the components from environmental factors such as moisture, humidity, and chemical exposure. Corrosion can lead to deterioration and failure of the electronic components, so the steel must be able to withstand these potential hazards. Another important requirement is that the special steel should have low magnetic permeability. Magnetic interference can negatively impact the performance of electronic components, especially in sensitive devices such as microchips. Therefore, the steel used in electronic components should have minimal magnetic properties to prevent any interference with the operation of the components. Furthermore, the steel must have good thermal conductivity to facilitate efficient dissipation of heat generated within the electronic components. This is particularly crucial in devices that generate a significant amount of heat, as inadequate thermal conductivity can lead to overheating and potential damage to the components. Lastly, the special steel used in electronic components should have high strength and durability to ensure longevity and reliability. The components are often exposed to mechanical stress, vibrations, and other external forces, so the steel must possess the necessary strength to withstand these conditions without deformation or failure. In summary, the requirements for special steel used in electronic components include excellent electrical conductivity, high corrosion resistance, low magnetic permeability, good thermal conductivity, and high strength and durability. Meeting these requirements is essential for ensuring the optimal performance and longevity of electronic devices.

- Q: What are the different methods of surface coloring for special steel?

- There are several different methods of surface coloring for special steel, each serving a specific purpose and achieving a distinct effect. Some of the common methods include: 1. Heat Treatment: Heat treatment is a popular method for surface coloring of special steels. This process involves exposing the steel to high temperatures, which causes a controlled oxidation reaction on the surface. The result is a layer of colored oxide that can vary in hue, ranging from golden yellow to deep blue or black. Heat treatment can also improve the hardness and corrosion resistance of the steel. 2. Electroplating: Electroplating is another common method used to color the surface of special steel. It involves immersing the steel in an electrolyte bath containing a metal salt solution. An electrical current is then passed through the bath, causing the metal ions to adhere to the steel surface, resulting in a thin layer of the desired metal coating. This method allows for a wide range of colors and finishes, depending on the metal used and the desired effect. 3. Chemical Coloring: Chemical coloring is a process that involves the use of chemical solutions to alter the surface color of special steel. This method typically involves treating the steel with a solution containing specific chemicals, such as oxidizing agents or dyes. By carefully controlling the composition and concentration of the solution, it is possible to achieve a variety of colors and finishes. This method is often used for decorative purposes and can produce vibrant and uniform coloration. 4. Physical Vapor Deposition (PVD): PVD is a technique used to deposit thin layers of material onto the surface of special steel. In this method, a solid material is vaporized using a high-energy source, such as an arc or plasma, and then condensed onto the steel surface. This process allows for the deposition of various materials, including metals, ceramics, and polymers, which can result in a range of colors and surface finishes. PVD coatings are known for their durability, wear resistance, and aesthetic appeal. 5. Laser Marking: Laser marking is a non-contact method that utilizes a focused laser beam to create permanent markings or colors on the surface of special steel. By adjusting the laser parameters, such as power, speed, and frequency, it is possible to achieve different colors and surface effects. Laser marking is often used for branding, identification, or decorative purposes, as it provides high precision and can create intricate patterns or designs. Overall, the choice of surface coloring method for special steel depends on various factors, including the desired color, durability, functionality, and cost considerations. Each method offers its own advantages and limitations, allowing for customization based on specific requirements and preferences.

- Q: Can special steel be used in the manufacturing of cutting-edge technology products?

- Yes, special steel can definitely be used in the manufacturing of cutting-edge technology products. Special steel is known for its high strength, durability, and resistance to corrosion, making it an ideal material for various applications in the technology industry. For example, in the production of smartphones, special steel can be used for the casing, providing excellent protection against impact and scratches while maintaining a sleek and modern design. Additionally, special steel can be utilized in the manufacturing of precision components for advanced machinery, such as robotics or medical devices, where high strength and reliability are crucial. Overall, special steel offers numerous advantages that make it a suitable choice for the production of cutting-edge technology products.

- Q: What are the different methods of joining special steel components?

- Various techniques exist for joining special steel components, each offering unique advantages and applications. Welding, brazing, soldering, mechanical fastening, and adhesive bonding are among the most commonly used methods. 1. Welding represents a widely employed method for joining special steel components. It involves melting the base metals and adding a filler material to create a robust bond. Depending on the specific requirements and properties of the steel components, different welding techniques like arc welding, gas welding, or laser welding can be utilized. 2. Brazing utilizes a filler material with a lower melting point than the base metals. This material is heated and distributed between the components, forming a strong bond as it solidifies. Brazing is particularly suitable for high-temperature applications and can be performed using a torch, furnace, or induction heating. 3. Soldering is similar to brazing but employs a lower melting point filler material known as solder. It finds common use in electrical and electronic applications, as well as for joining small or delicate steel components. Soldering necessitates less heat and can be accomplished using a soldering iron or hot air gun. 4. Mechanical fastening involves joining components using mechanical means such as screws, bolts, nuts, or rivets. This method is often preferred when disassembly or reassembly is necessary, as it allows for easy removal and replacement of components. Mechanical fastening is suitable for applications requiring a strong and reliable joint, especially when welding or brazing may not be feasible. 5. Adhesive bonding is another method employed for joining special steel components. It entails applying an adhesive material to the mating surfaces, which then cures or hardens to create a robust bond. Adhesive bonding is commonly used when a continuous joint is required or when joining dissimilar materials. It offers advantages in applications necessitating vibration damping or sealing. The selection of the appropriate joining method depends on various factors such as the specific requirements of the application, the properties of the steel components, and the desired strength and durability of the joint. Each method has its own strengths and limitations.

- Q: Can special steel be used for making aerospace components?

- Yes, special steel can be used for making aerospace components. Special steel alloys, such as stainless steel or titanium alloys, possess high strength, excellent corrosion resistance, and good heat resistance, making them suitable for aerospace applications where lightweight, durability, and resistance to extreme conditions are essential.

- Q: What are the different types of high-strength steel?

- There are several types of high-strength steel, including high-strength low-alloy (HSLA) steel, ultra-high-strength steel (UHSS), dual-phase (DP) steel, and transformation-induced plasticity (TRIP) steel. Each type has unique properties and is used in various industries for applications that require exceptional strength and durability.

- Q: How does special steel contribute to the manufacturing of molds and dies?

- Special steel plays a crucial role in the manufacturing of molds and dies. Molds and dies are essential tools used in various industries, such as automotive, aerospace, and electronics, for shaping and forming materials into desired shapes and sizes. These tools need to be durable, resistant to wear and tear, and capable of withstanding high temperatures and pressures. Special steel, also known as tool steel, possesses unique properties that make it an ideal material for molds and dies. Firstly, it has a high hardness, which allows the tools to maintain their shape and surface integrity even when subjected to extensive use and repetitive impacts. This hardness also helps in achieving precision and accuracy in the final product. Additionally, special steel has excellent wear resistance, which is essential as molds and dies come into contact with various materials during the manufacturing process. The resistance to wear ensures that the tools have a longer lifespan, reducing the need for frequent replacements and minimizing production downtime. Moreover, special steel has good toughness, meaning it can absorb and withstand high impact forces without fracturing or breaking. This property is crucial in molds and dies as they often undergo significant stress during the manufacturing process, especially when dealing with materials that require high pressure or extreme temperatures. Special steel is also known for its high heat resistance, enabling molds and dies to withstand the elevated temperatures used in certain manufacturing processes, such as injection molding or metal forging. This heat resistance prevents the tools from warping or losing their shape, ensuring consistent and accurate production. Furthermore, special steel can be easily machined and shaped, allowing manufacturers to create complex and intricate designs for molds and dies. This versatility is vital as different industries require unique tool designs to meet their specific manufacturing needs. In conclusion, special steel is an essential material for the manufacturing of molds and dies due to its high hardness, wear resistance, toughness, heat resistance, and machinability. Its unique properties contribute to the durability, precision, and efficiency of molds and dies, ultimately enhancing the quality and productivity of various manufacturing processes.

Send your message to us

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords