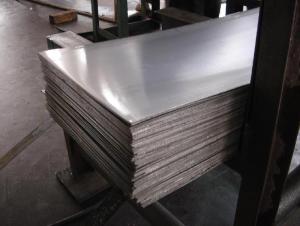

Low price aluzinc coated galvanized steel sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Galvalume should not be used on, in, or around concrete or mortar. Concrete and mortar are highly

alkaline environments. Bare Galvalume and painted Galvalume sheets suffer rapid corrosion when

in contact with mortar and concrete. Bare Galvanized and painted Galvanized perform better in this

type of environment.

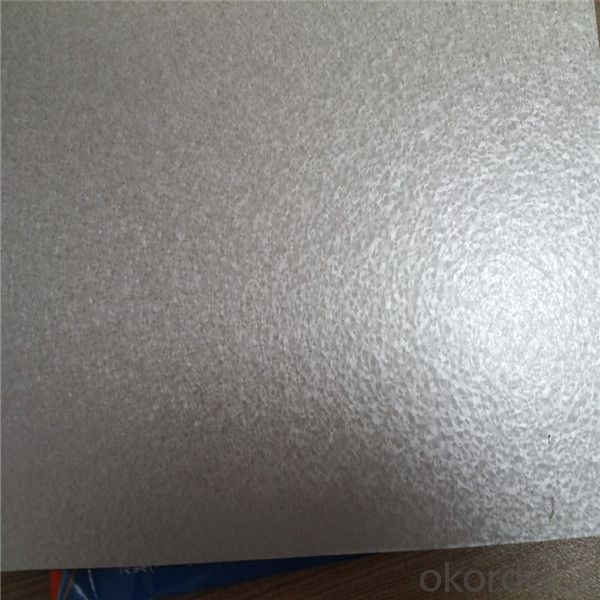

The combination of zinc and aluminum in Galvalume enhances both the positive and negative effects

of aluminum. Galvalume has barrier corrosion resistance and heat resistance similar to aluminized

material and good bare edge galvanic protection and forming qualities like galvanized material. Consequently,

Galvalume and Galvalume Plus will resist rust, the elements and fire while providing a sturdy and protective covering.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

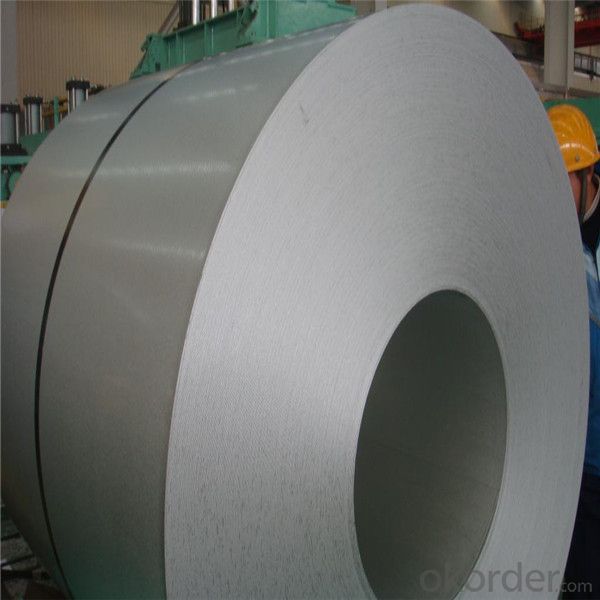

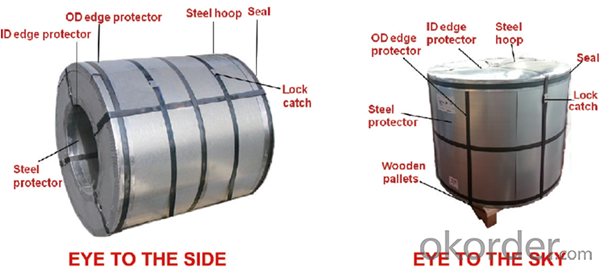

Packaging & Shipping

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: Are steel sheets resistant to rust or corrosion?

- Yes, steel sheets are resistant to rust or corrosion due to the presence of chromium, which forms a protective layer on the surface preventing oxidation.

- Q: What is the typical elongation of a steel sheet?

- The typical elongation of a steel sheet varies depending on the specific grade and thickness of the sheet. However, on average, steel sheets can have an elongation of around 20-30% before they reach their breaking point.

- Q: What is the typical cost of steel sheets compared to aluminum?

- The typical cost of steel sheets is generally lower compared to aluminum. Steel is one of the most widely used materials in construction and manufacturing due to its strength, durability, and affordability. Steel sheets are produced in large quantities and are readily available in various grades and thicknesses, making them more cost-effective. On the other hand, aluminum is a lightweight and corrosion-resistant metal, which makes it desirable for certain applications such as aerospace or automotive industries. However, aluminum is more expensive to produce and process compared to steel, resulting in higher costs for aluminum sheets. Ultimately, the cost difference between steel and aluminum sheets will depend on factors such as market demand, current metal prices, and specific requirements of the project or application.

- Q: What are hot and cold plates?

- Production process: in the production process without heating, so there is no pitting and iron oxide defects often appear in the hot rolling, good surface quality, high degree of finish. Moreover, the cold-rolled products have high dimensional accuracy, and the performance and organization of the products can meet some special requirements, such as electromagnetic properties and deep drawing properties.

- Q: What is the maximum thickness of a steel sheet?

- The maximum thickness of a steel sheet can vary depending on various factors such as the type of steel, the manufacturing process, and the intended use. However, generally speaking, steel sheets can be manufactured up to a thickness of around 25 millimeters (1 inch) or even thicker in some cases. Thicker steel sheets are often used in heavy-duty applications such as construction, shipbuilding, and industrial machinery where strength and durability are crucial. It is important to consult with manufacturers or industry standards to determine the specific maximum thickness for a particular type of steel sheet.

- Q: How are steel sheets protected during storage and handling?

- Steel sheets are typically protected during storage and handling through various measures such as applying a protective coating, using separators to prevent direct contact, and storing them in a controlled environment to avoid moisture and corrosion.

- Q: Can steel sheets be used for modular construction or prefabricated buildings?

- Modular construction and prefabricated buildings can utilize steel sheets for their construction. The strength, durability, and versatility of steel make it a popular choice for this type of construction. Steel sheets can be used to build the framework, walls, and roof of prefabricated buildings. Modular construction involves fabricating building components in a controlled factory environment. Steel sheets can be easily cut, shaped, and welded to create customized building modules. These modules can then be transported to the construction site and quickly assembled. The use of steel sheets ensures precision and consistency in the manufacturing process, resulting in high-quality components. Steel's excellent strength-to-weight ratio makes it ideal for modular construction. Using steel sheets allows for lightweight yet sturdy building modules. This is advantageous for transportation and installation, as it reduces the overall weight and cost associated with shipping and lifting the modules. Furthermore, steel is a durable material that can withstand various weather conditions and environmental factors. It is resistant to fire, termites, and rot, making it a reliable choice for long-lasting prefabricated buildings. Steel sheets can also be treated to enhance their corrosion resistance, protecting the building against rust and deterioration. In addition to its strength and durability, steel offers design flexibility. Steel sheets can be easily manipulated to create different shapes and forms, allowing for diverse architectural styles and configurations. This versatility makes steel an attractive option for architects and builders looking to create aesthetically pleasing and functional prefabricated buildings. Overall, steel sheets are suitable for modular construction and prefabricated buildings due to their strength, durability, versatility, and design flexibility. Using steel in this construction method enables efficient manufacturing, easy transportation, and quick assembly, resulting in cost-effective and high-quality buildings.

- Q: Can steel sheets be recycled into other steel products?

- Yes, steel sheets can be recycled into other steel products.

- Q: Can steel sheets be used for electrical switchgear?

- Yes, steel sheets can be used for electrical switchgear. Steel is a common material used in the construction of switchgear cabinets due to its durability, strength, and ability to protect the electrical components inside from external factors such as moisture, dust, and physical damage. Additionally, steel provides grounding properties necessary for electrical safety.

- Q: What is the typical composition of stainless steel sheets?

- The typical composition of stainless steel sheets is primarily made up of iron, with a significant amount of chromium (around 10-20%) and smaller amounts of other elements such as nickel, carbon, and manganese. This combination gives stainless steel its corrosion-resistant properties and makes it suitable for various applications.

Send your message to us

Low price aluzinc coated galvanized steel sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords