Color glazed steel sheet with cheap steel prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35234 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

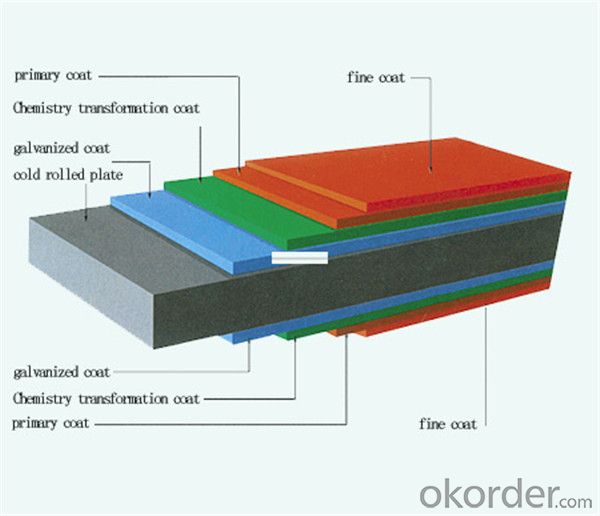

Pre-Painted Galvanised Steel (PPGI) is a metallic coated steel product with improved

corrosion resistance where the premium range PPGI also include features such as dirt

staining resistance, color retention, scratch resistance (ScratchCore™) and solar reflectance

(HeatBounce™). PPGI is commonly used in building materials such as roofing, cladding, walling, and etc.

Colors

All types of colors available as per RAL codes mainly White, Red, Blue, Green, Cream, Orange and various others.

Applications

Building industry, profiling, corrugation, furniture making, sign boards and for sandwich panels.

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

| ||||

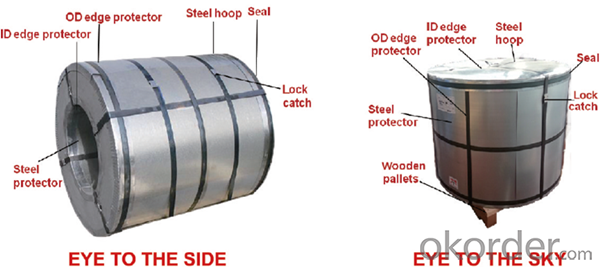

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: What is the process of applying anti-fingerprint coatings to steel sheets?

- The process of applying anti-fingerprint coatings to steel sheets typically involves several steps. Firstly, the steel sheets are thoroughly cleaned and degreased to ensure a smooth surface. This is typically done using solvents or alkaline cleaners. Next, the sheets are rinsed and dried to remove any remaining residue. Once clean, a primer or adhesion promoter may be applied to enhance the bonding between the steel and the anti-fingerprint coating. The anti-fingerprint coating is then applied onto the steel sheets using various methods such as spraying, dipping, or roll coating. The coating material is usually a combination of polymers, resins, and additives that provide the desired anti-fingerprint properties. After the coating is applied, the steel sheets are cured or dried, depending on the specific coating technology. This step ensures that the coating adheres properly to the surface and develops its anti-fingerprint characteristics. Lastly, the coated steel sheets may undergo quality checks and inspections to ensure that the coating thickness, appearance, and performance meet the desired standards. This can involve visual inspections, adhesion tests, and fingerprint resistance evaluations. Overall, the process of applying anti-fingerprint coatings to steel sheets involves cleaning, priming, coating, curing, and quality control measures to achieve a durable and effective anti-fingerprint surface on the steel.

- Q: What is the difference between a smooth and embossed steel sheet?

- A smooth steel sheet is characterized by its flat and uniform surface, lacking any textures or patterns. It is typically produced by rolling the steel through a series of rollers to achieve a sleek and even finish. Smooth steel sheets are commonly utilized in industries where a seamless and polished appearance is desired, such as in architectural and interior design, automotive manufacturing, and appliance production. On the other hand, an embossed steel sheet possesses a textured or patterned surface. This texture is created by pressing the steel sheet between embossing rollers, which imprint a design onto the surface. The embossed pattern can take various shapes, including diamonds, squares, or waves, and it adds a decorative and tactile element to the sheet. Embossed steel sheets are often employed in industries like furniture manufacturing, signage production, and decorative metalwork. In terms of functionality, smooth steel sheets are typically chosen for applications that require a clean and unadorned surface, such as for painting, coating, or other surface treatments. They serve as a blank canvas for further customization or finishing processes. In contrast, embossed steel sheets provide a visually appealing and distinctive texture that can enhance the aesthetic appeal of a product or structure without the need for additional surface treatments. Furthermore, the surface texture of a smooth steel sheet tends to be more resistant to fingerprints, smudges, and dirt accumulation compared to an embossed steel sheet. This makes smooth steel sheets easier to clean and maintain in applications where cleanliness is crucial, such as in the food processing or healthcare industries. Overall, the primary distinction between a smooth and embossed steel sheet lies in their appearance, functionality, and suitability for specific applications. While smooth steel sheets offer a clean, consistent, and versatile surface, embossed steel sheets provide a decorative and textured finish that can elevate the visual appeal of a product or structure.

- Q: Are steel sheets easy to install?

- Yes, steel sheets are relatively easy to install due to their lightweight and flexible nature. They can be easily cut and shaped to fit various surfaces, making the installation process more convenient and efficient. Additionally, steel sheets often come with pre-drilled holes, which further simplifies their installation.

- Q: Can steel sheets be used for kitchen backsplashes?

- Yes, steel sheets can be used for kitchen backsplashes. Steel is a durable and easy-to-clean material, making it a suitable choice for a kitchen backsplash application.

- Q: Can steel sheets be used for manufacturing machinery parts?

- Indeed, machinery parts can be manufactured using steel sheets. Steel, as a material, possesses remarkable versatility and durability, thereby offering exceptional strength and rigidity necessary for the production of diverse machinery components. The malleability, ease of cutting, and weldability of steel sheets enable the creation of intricate shapes and structures essential for machinery parts. Furthermore, steel exhibits commendable resistance against corrosion, guaranteeing the longevity of the machinery components. Moreover, steel sheets ensure dimensional stability and can endure substantial loads and elevated temperatures, rendering them a perfect selection for the manufacturing of machinery parts.

- Q: How do steel sheets handle chemical exposure?

- Steel sheets are highly resistant to chemical exposure due to their inherent corrosion resistance. The chemical composition and protective coatings on steel sheets make them capable of withstanding a wide range of chemical substances without significant degradation or damage.

- Q: Can steel sheets be formed into corrugated panels?

- Yes, steel sheets can be formed into corrugated panels.

- Q: Can steel sheets be used for insulation?

- No, steel sheets cannot be used for insulation. Steel is a good conductor of heat and electricity, so it does not retain heat or prevent heat transfer effectively. In fact, steel sheets can actually conduct heat and cold, making them poor insulators. Insulation materials such as fiberglass, foam, or cellulose are much better at trapping heat and preventing its transfer, which makes them ideal for insulation purposes.

- Q: Can the steel sheets be easily cleaned?

- Certainly, steel sheets can be effortlessly cleaned. Renowned for their durability and low-maintenance nature, steel sheets can be swiftly wiped down with a damp cloth or sponge accompanied by mild soap or detergent. In the case of stubborn stains or grime, a non-abrasive cleaner is recommended. Moreover, steel sheets exhibit exceptional resistance to rust and corrosion, rendering them well-suited for diverse settings and ensuring hassle-free maintenance in the long term.

- Q: What is the difference between hot-rolled and cold-rolled steel sheets?

- The manufacturing process and resulting characteristics of steel sheets differ between hot-rolled and cold-rolled varieties. Hot-rolled steel sheets are produced by heating a large steel slab and passing it through high-temperature rollers. This allows for easy shaping and forming into various sizes and thicknesses. The elevated temperature also removes any residual stress in the steel, making it more flexible and moldable. Consequently, hot-rolled steel sheets possess a rougher surface finish and may exhibit a thin oxide layer called scale. However, they are generally less expensive and come in a wider range of sizes. In contrast, cold-rolled steel sheets are created by cooling down the hot-rolled steel and passing it through rollers at room temperature. This process not only reduces the steel's thickness but also enhances its surface finish and dimensional accuracy. Cold-rolling gives the steel sheets a smooth and shiny appearance, making them suitable for applications where aesthetics matter. Additionally, cold-rolling improves the steel's strength and hardness, making it more appropriate for high-stress uses. However, cold-rolled steel sheets are typically more costly due to the additional processing involved. In summary, hot-rolled steel sheets offer greater formability and lower cost, but have a rougher surface finish and may exhibit scale. On the other hand, cold-rolled steel sheets have superior surface finish, dimensional accuracy, and strength, but are pricier. Choosing between hot-rolled and cold-rolled steel sheets depends on the specific requirements of the application, including desired surface finish, strength, and cost considerations.

Send your message to us

Color glazed steel sheet with cheap steel prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35234 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords