GALVANIZED STEEL COIL SGCC

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

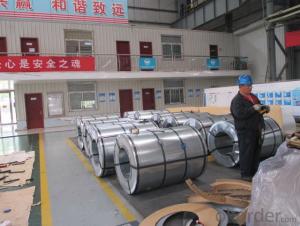

Prime Galvanized steel coil

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

Hot dip galvanized steel coil

Technical Standard:JIS 3302 / ASTM A653 / EN10143/ GB/T 2518

Grade:DX51D/ S250,280,320GD,SGCC,SGHC,SGH340,SGH400,SGH440,G450,G550

Types:Commercial / Drawing / Deep Drawing / Structural quality

Width: 900mm/1000mm/1219mm/1200mm/1220mm/1250mm

Thickness: 0.2mm~4.0mm

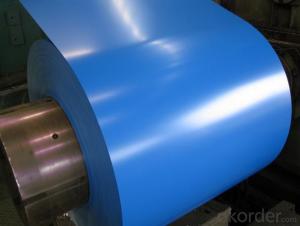

Type of coating: galvanized

Zinc coating: Z40-275g/m2,Z40-Z450g/m2

Surface treatment:zero spangle / regular spangle/ big spangle

ID coil: 508mm or 610mm

Coil weight: 3-10/MT per coil

Package:Properly packed for ocean freight exportation in 20''container

Application::home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

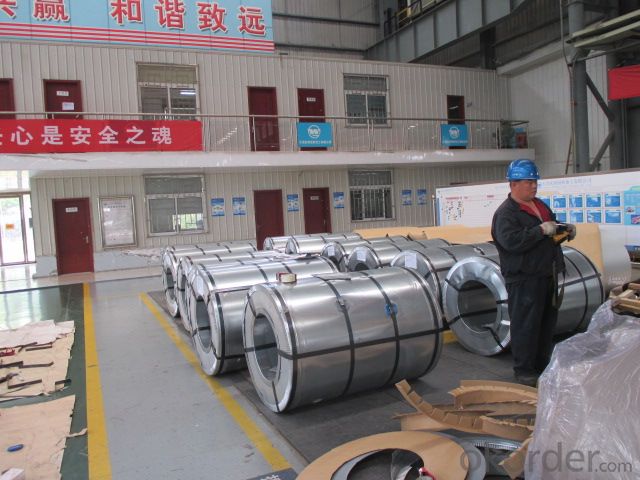

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of products

- Q: Can steel coils be coated with zinc?

- Yes, steel coils can be coated with zinc through a process called hot-dip galvanization or electroplating. This coating of zinc helps protect the steel from corrosion and rust, extending its lifespan and improving its durability.

- Q: What are the different methods of heat treatment for steel coils?

- Steel coils can undergo various heat treatment methods, each offering unique benefits and applications. One method is annealing, where steel coils are heated to a high temperature and gradually cooled in a controlled environment. This relieves internal stresses, enhances ductility, and refines the grain structure, resulting in softer and more machinable steel. Another method, normalizing, is similar to annealing but involves a faster cooling process. It aims to refine the grain structure and achieve uniform hardness throughout the coils. Normalizing also eliminates residual stresses and improves mechanical properties. Quenching and tempering is a two-step process that begins with heating the coils to a high temperature and rapidly cooling them in a quenching medium like oil or water. This creates a hard and brittle phase called martensite. To enhance toughness and reduce brittleness, the coils are reheated to a lower temperature and held there for a specific duration, a process known as tempering. Tempering helps decrease internal stresses and increase ductility and toughness. Case hardening is another method used to increase the surface hardness of steel coils while maintaining a soft and ductile core. This involves heating the coils in a carbon-rich atmosphere, allowing carbon to diffuse into the surface layer. The result is a hard outer layer, known as the case, while the core retains desired mechanical properties. Stress relieving is performed by heating the coils to a specific temperature and holding them there for a sufficient time. This minimizes residual stresses from previous manufacturing or heat treatment processes. Stress relieving improves dimensional stability, reduces the risk of distortion or cracking, and enhances overall performance. The choice of heat treatment method depends on desired properties, intended application, and specific requirements of the end product. Each method has its own advantages and can be customized to achieve the desired balance between hardness, toughness, ductility, and other mechanical properties.

- Q: How are steel coils used in the production of transportation equipment?

- Steel coils are used in the production of transportation equipment as they provide the necessary strength and durability required for components such as chassis, frames, and body panels. These coils are shaped, cut, and welded to create different parts, ensuring the structural integrity and safety of vehicles such as cars, trucks, and trains.

- Q: I know sterling silver can tarnish, so I was just wondering, how does stainless steel hold up?

- Stainless okorder

- Q: How are steel coils protected from extreme weather conditions?

- Steel coils are typically protected from extreme weather conditions using various methods such as covering them with waterproof wraps, storing them in climate-controlled warehouses, or applying anti-corrosion coatings. These measures ensure that the coils are shielded from moisture, temperature fluctuations, and other environmental factors that could potentially damage or degrade the steel.

- Q: Can steel coils be coated with ceramic?

- Yes, steel coils can be coated with ceramic. Ceramic coatings provide a protective layer that enhances the corrosion resistance, heat resistance, and durability of the steel coils. Additionally, ceramic coatings can also offer improved electrical insulation and thermal barrier properties.

- Q: will peircers use surgical steel? how do you know for sure what they are using?

- that should be what they use.mine does.instead of wondering why not ASK??

- Q: does he use a nylon guitar or steel?

- The correct term for what you are looking at is a classical guitar. Classical guitars always have nylon strings (steel strings will tear them apart). There is no such thing as a nylon guitar, and if there were, I don't think it would sound very good, although Mario Maccaferri did make some plastic ones that are quite collectible now. Steel guitar - as opposed to steel-string guitar which is what I think you mean - is the name of an entirely different instrument that doesn't look much like a guitar at all. There are also steel-bodied guitars which have a mechanical amplification system built in. However, normal classical and steel-string guitars are made of wood. A classical guitar usually has a slotted headstock with wide rollers, a wide uncambered fretboard, a 12-fret neck, an ornate soundhole rosette, no pickguard, a tied bridge with a straight saddle, and fan bracing. A steel-string guitar usually has a solid headstock or a slotted headstock with narrow rollers, a narrow cambered fretboard, a 14- or 12-fret neck, a simple rosette, a pickguard, a pin bridge with a slanted saddle, and X bracing.

- Q: How are steel coils used in the production of electrical enclosures?

- Steel coils are used in the production of electrical enclosures as they are shaped and formed into sheets, which are then cut, bent, and welded to create the enclosure's structure. The steel coils provide the necessary strength and durability required to protect the electrical components inside the enclosure while also offering resistance to various environmental factors such as moisture, heat, and impact.

- Q: What are the environmental and social impacts of mining, processing and using steel?

- I don't think society as we know it could exist without it. As for the enviroment there is damage from mining, processing and from using steel equiptment.

Send your message to us

GALVANIZED STEEL COIL SGCC

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords