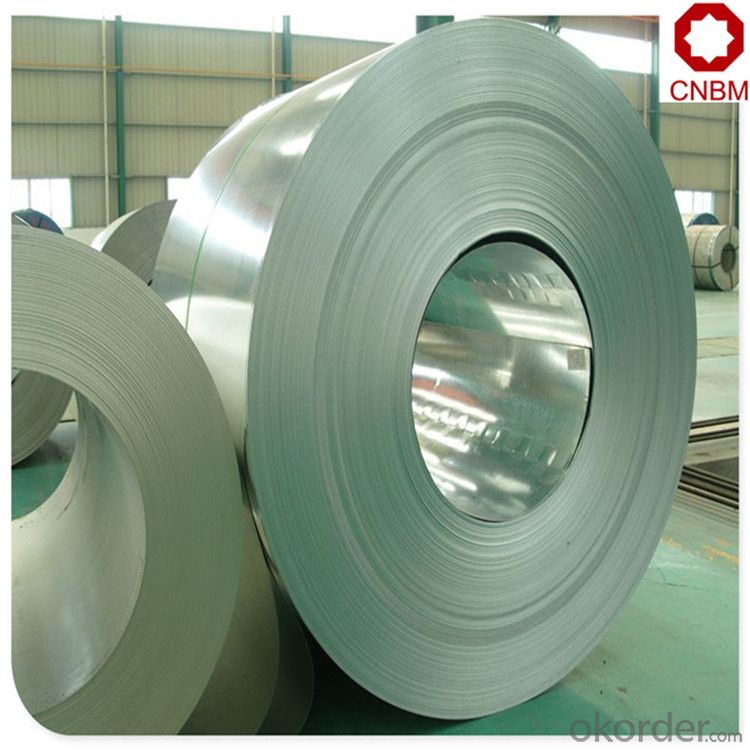

Galvanized coil in steel material SGCC hot-dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 34257 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

Certificate:

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development

- Q: I'm planning to buy a pair of Doc Marten boots but I want some steel toed ones. I don't know if all of them are steel toed, or only some of them, or what?

- Dr Martens Steel Toe Boots

- Q: How are steel coils priced and traded in the market?

- Steel coils in the market are priced and traded based on a variety of factors. The primary determinant is the current dynamics of supply and demand in the steel industry. When demand for steel coils is high, prices tend to increase, and vice versa. The cost of raw materials, such as iron ore and coal, is another crucial factor in determining the price of steel coils. Fluctuations in the prices of these materials can directly impact the pricing of steel coils. Furthermore, the price of steel coils is influenced by their quality and specifications. Coils with desirable characteristics, such as strength, corrosion resistance, or surface finish, may command a higher price in the market. Steel coils are traded through different platforms, including physical exchanges, futures contracts, and over-the-counter (OTC) markets. Physical exchanges allow buyers and sellers to trade steel coils by exchanging physical deliveries. Futures contracts, on the other hand, enable traders to buy or sell steel coils at a predetermined price and future date, providing a way to hedge against price fluctuations. The OTC market provides an alternative avenue for trading steel coils, where buyers and sellers negotiate and agree on prices directly without involving a formal exchange. This allows for flexibility and customization in trading, catering to specific requirements. In conclusion, the pricing and trading of steel coils in the market are influenced by factors such as demand and supply dynamics, raw material costs, quality specifications, and the availability of different trading platforms. It is a complex process that requires careful consideration of various factors to determine fair prices and facilitate efficient trading.

- Q: I know this is an alloy, but can it be mixed to form a superior steel? Therefore less likely to stain?

- In general, the austenitic stainless steels are considered to have the best overall corrosion resistance of all the stainless steels and to be the most resistant to industrial atmospheres and acid media. As the corrosion conditions become more severe (e.g. higher temperatures and stronger acids), more alloy content above that in type 304 is required. The addition of over 2% Mo to austenitic stainless steels increases resistance to pitting. Type 316 is a popular alloy in this class and contains 2.5% Mo.

- Q: does anyone out there know where to get a good deal on a pedal steel guitar? i am from northern indiana and i'm willing to travel some if i have to.i am just getting into pedal steel guitar and i really don't have any idea what i need. i don't know how to play a guitar (i do know how to play the piano and the drums) at all but i want to learn to play the pedal stell guitar and i can't do that without getting one first so, if anyone can help me out i would greatly appreciate it! :o)

- I agree with everything that Lester said. Another thought is to consider starting on a lap steel guitar rather than a pedal steel - its related, a little easier to learn on, and less expensive. Once you get proficient on the lap steel, you can move up to the pedal steel. Good luck!

- Q: Which one is stronger steel or metal ( for bow and arrows) please answer I need it for a book I'm writing

- hi Asking this question in engineering category would give you the following answer steel is a subcategory of metals moreover steel is iron with some other additions( mainly carbon) strong in the engineering sense is not a specific word..i mean we , in engineering, have many scales to categorize metals ( which include steel)..like hardness,corrosion,elasticity, and even heat conductivity...every metal could be strong in some and weak in other but i can understand that you are not an engineering type :) that's why here's a special answer for you steel usually has the silver shiny color ( i am not sure all grades of steel have this color)...it would be more EPIC to use steel bow and arrows... if it's a fictitious books...you can just use Iron or any name you can made up... You can search....how did the ancients make their bows and arrows? thanks :)

- Q: What is the weight of a typical steel coil?

- The weight of a typical steel coil can vary depending on its size and thickness. However, a common range for the weight of a steel coil is between 5 to 15 tons.

- Q: I want to know the special characters or the advantages of the corton steel. In what cases it is recommended to use?Thank you.

- *It is Corten steel.Grade A B. *Weathering steel, best-known under the trademark COR-TEN steel, is a group of steel alloys which were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years. United States Steel Corporation (USS) holds the registered trademark on the name COR-TEN. Although USS sold its discrete plate business to International Steel Group (now Arcelor-Mittal) in 2003, it still sells COR-TEN branded material in strip-mill plate and sheet forms. In some areas it may be known without the hyphen as Corten steel. The original COR-TEN received the standard designation A242 (COR-TEN A) from the ASTM International standards group. Newer ASTM grades are A588 (COR-TEN B) and A606 for thin sheet. All alloys are in common production and use. It is a weather-resistant steel which is used in containers and hot flue gas line. The American Corten A Steel has a composition of C, 0.12; Si, 0.5; Cu, 0.5; Cr, 0.8; P, 0.1 and Mn, 0.5%. Although the tensile strength is less than 494 MPa the yield is in the region of 371 MPa. The combination of copper and phosphorus also increases the resistance to atmospheric corrosion which is important when thinner plates are used. The original steel A suffers a decrease in yield strength and notch ductility in thickness over 25 mm, to overcome which Corten B was developed-C 0.14; P 0.04; Mn 1.1; Cr 0.5; Cu 0.4; V 0.1; Bol Al 0.02. *COR-TEN A applies to plates up to 12.5mm in thickness, COR-TEN B applies to plates up to 50mm in thickness. *It has been used in bridge and other large structural applications such as the New River Gorge Bridge, the newer span of the Newburgh-Beacon Bridge, and the creation of the Australian Centre for Contemporary Art (ACCA). It is very widely used in marine transportation, in the construction of shipping containers.

- Q: Can steel coils be stamped?

- Yes, steel coils can be stamped. Stamping is a common process used to shape and form steel coils into various shapes and sizes for different industrial applications.

- Q: If a make a dish antenna of steel and of fiberglass, which would be more heavy and also which would be more expensive?

- Why not go one better. An aluminum mesh would be lighter than both for the same size and would not need to be painted. It would probably be more expensive than the steel however.

- Q: My uncle got me some new 'Nam style jungle boots at the px at Fort Worth JSB, and he told me that back in Vietnam, they used to issue guys steel sole boots, that had a sole reinforced with a steel plate, as punji stick d-fence. Is this true, it sounds logical, but I can't figure out how a steel plate in the sole would work. My uncle is kind of a BS'er, plus he wasn't even in Vietnam, much less the Infantry, much less combat, but he was in USAF at the time.

- The steel plate in the boot was about 5 cm long and 2 cm wide, it was located in the midsection of the boot sole but did not cover the heel. Prolonged wear, the humidity and soakings eventually caused the steel piece to break out of the mounding in the inside of the boot and cause blisters.

Send your message to us

Galvanized coil in steel material SGCC hot-dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 34257 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords