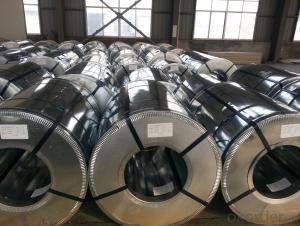

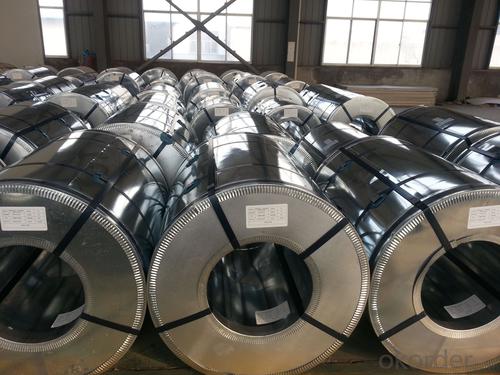

HOT DIP GALVANIZED STEEL IN COIL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HOT DIP GALVANIZED STEEL IN COIL

thickness:0.13-2.0mm

width:600-1500mm

material:SGCC,DX51D,Q195

coil weight:3-8 ton

Application:construction field ,ships building industry ,Petroleum and chemical industries ,war and electricity industries ,food processing and medical industry,boiler heat exchanger, machinery and hardware fields

Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts

Package:covered with waterproof-paper,strapped by strips. Standard seaworthy export package:4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection.

SPANGLE: normal spangle, large spangle, small(min) spangle, zero spangle

Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds

- Q: If rail ties were melted, would they be like any other type of steel?

- Steel okorder ... If care is not taken in the method used to melt the steel that alloy will change because the carbon will burn in the process. Also part of a steels rating is a result of heat treatments used. When melted it will loose those properties. By the way rail road ties are either wood or concrete- not steel.

- Q: How are steel coils used in the production of oil and gas machinery?

- Steel coils are commonly used in the production of oil and gas machinery for various purposes. They are utilized in the manufacturing of pipes, tanks, and pressure vessels, providing structural strength and durability to withstand the harsh conditions of oil and gas operations. Additionally, steel coils are shaped and formed into components such as valves, fittings, and flanges, which are crucial for the proper functioning of the machinery. Overall, steel coils play a vital role in ensuring the reliability and efficiency of oil and gas machinery.

- Q: What is the average price of a steel coil?

- The average price of a steel coil can vary depending on several factors such as the type of steel, the thickness and width of the coil, the market demand, and the location of purchase. Generally, the price can range from $500 to $1500 per metric ton. However, it is important to note that prices are subject to fluctuations in the steel market, which can be influenced by global economic conditions, trade policies, and supply-demand dynamics. Therefore, it is advisable to consult with steel suppliers or monitor market trends to get the most accurate and up-to-date pricing information.

- Q: What are the different types of steel processing equipment for coils?

- There are several types of steel processing equipment used for coils, including slitting lines, cut-to-length lines, blanking lines, and coil-to-coil lines. Slitting lines are used to slit wide steel coils into narrower strips, while cut-to-length lines are used to cut coils into specific lengths. Blanking lines are used to cut shapes out of coils, and coil-to-coil lines are used to transfer coils from one processing stage to another.

- Q: How are steel coils uncoiled?

- Steel coils are typically uncoiled using a mechanical device called a decoiler. The decoiler feeds the steel coil through a set of rollers, which gradually unwinds and straightens the coil, allowing it to be used for various applications.

- Q: Has anyone painted their appliences with stainless steel paint? I found on the internet what is called Thomas Liquid stainless steel paint. If you have used it for your kitchen appliences or cabinets, how were the results? How hard was it to apply? Would you recommend it?

- I am also considering buying Thomas Liquid Steel, but have not used it or seen it used before. I did call a store that sells this product and they said they saw the mfg demo the product at a trade show. The store rep told me that the results were absolutely amazing. I think I will buy the medium kit direct from the mfg for $129 and give it a test run first on something other than my kitchen appliances.

- Q: How are steel coils used in the production of household goods?

- Steel coils are an essential component in the production of various household goods. These coils are typically made from high-quality steel and are manufactured to specific dimensions and thicknesses to meet the requirements of different products. One of the primary uses of steel coils in household goods production is in the manufacturing of appliances such as refrigerators, washing machines, and dishwashers. The coils are used to create the body and framework of these appliances, providing strength, durability, and stability. Additionally, steel coils are often used in the production of smaller household appliances like toasters, blenders, and coffee makers. Furthermore, steel coils are also used in the production of furniture, particularly in the manufacturing of metal frames for chairs, tables, and cabinets. These coils provide the necessary support and structural integrity to the furniture, ensuring long-lasting durability. Another significant application of steel coils in household goods production is in the production of shelving units and storage solutions. Steel coils can be shaped and formed to create sturdy shelves and racks that can hold heavy items and withstand regular use. These shelves are commonly used in kitchens, garages, and storage rooms to organize and store various household items. In summary, steel coils play a crucial role in the production of household goods. They are used to create the framework, structure, and support for appliances, furniture, and storage solutions. Their strength, durability, and versatility make them an ideal material for manufacturing a wide range of household products that are designed to withstand everyday use.

- Q: Can steel coils be coated with magnetically attractive materials?

- Yes, steel coils can be coated with magnetically attractive materials. This process is commonly known as electromagnetic coating or magnetic coating, where a thin layer of magnetically attractive material, such as iron or nickel, is applied onto the surface of the steel coil. This coating enhances the magnetic properties of the steel, making it more responsive to magnetic fields and enabling it to attract or be attracted by magnets.

- Q: I am building a robot for Bots IQ. In doing so i have the option of building the the armor of my robot out of titanium or tool steel.. which would be the better option.Brief description of Bots IQ: It is a competition where 2 15lb robots go and attack each other with spinning blades, hammers or whatever is designed.

- I would have to say titanium , but in doing so I am having to assume you have access to some very serious machinery.This is because Ti is extremely difficult to work and also work hardens, which could lead to cracking and failure.The other problem is that Ti is also very hard to weld .It seems tool steel is the choice for ease of working and weldability, so unless you can buy the bits you need precut or made then I'd say tool steel,preferably something along the lines of ramax.Your other option is spring steel as this is workable and gets hardened after shaping.

- Q: I've been looking into battle-ready katanas a lot lately. And I've come across some debates between the best forges and steels to be used for them. The functional katanas I use now are Musashi brand katanas, using 1045 carbon steel. They each cost roughly $200-$250. The straight carbon steels are mentioned in the debates, but they aren't very sophisticated in their design. Now the higher end of this middle class of katana ($250-$1000) uses higher carbon. spring, damascus, and other various steels and combinations. I've heard a lot about the strength of damascus steel and it's cutting power. But I look for more than that. I've also been looking at (and for) durability, flexibility, and how well it stands up to contact. So I guess what I'm asking is for the opinion of people who have used these steels, and an answer on what the community thinks is the best steel for a mid range ($250-$1000) battle-ready katana. Looking forward to some good answers.

- There is no such thing as a battle ready katana... if it is not ready for battle - it is not a katana. Having said that: The hardness of the cutting edge depends on the carbon content the better (in general). 1045 is poor quality steel for sword manufacture. Musashi swords are cheap pieces of crap. 1060 is better. Some manufacturers use modern materials that aren't perhaps consistent with traditional manufacture, like 9260 silicon spring steel or even L6 Bainite. Damascus steel is not a type of steel at all. It is a folding technique that creates a wavy grain in the metal. It may or may not mean that a sword is good. No swords will stand up to contact with other swords. They will inevitably be damaged. The best way to find a quality sword is to ask you instructor. There are no quality swords under a thousand dollars. The answer also depends on what you are going to do with the sword. It may also depend on the style or school of swordsmanship.

Send your message to us

HOT DIP GALVANIZED STEEL IN COIL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords