Hot-Dip Galvanized Steel Coil of origen of China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Coil Description:

Hot-dip galvanized steel coil are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

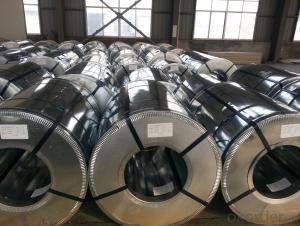

3.Hot-Dip Galvanized Steel Coil Images

4.Hot-Dip Galvanized Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: SPCC, SPCD, Q195, DX51D

Thickness: 0.15-5.0mm

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized

Application: Container Plate

Special Use: High-strength Steel Plate

Width: 600-1250mm

Length: depends

commodity: hot dipped galvanized steel coil

technique: cold rolled

thickness: 0.15-5.0mm

width: 600-1500mm

surface treatment: galvanized

zinc coating: 50-275g/m2

coil weight: 3-7 tons

coil ID: 508/610mm

spangle: zero spangle, regular spangle, small spangle, big spangle

payment term: by L/C or T/T

5.FAQ of Hot-Dip Galvanized Steel Coil

What’s the application of this product?

There are many applications for this product. For example, roofing, cladding, decking, tiles, sandwich walls, etc.

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: How are steel coils used in the manufacturing of tools and equipment?

- Steel coils are used in the manufacturing of tools and equipment as they serve as the primary raw material for many applications. The coils are first processed to the desired thickness and then cut into different shapes and sizes to create various components. These components are then further processed, machined, or assembled to form the final tools and equipment. Steel coils provide the necessary strength, durability, and versatility required in the manufacturing process, making them an essential element in producing high-quality tools and equipment.

- Q: What are the common coil loading and unloading procedures?

- Common coil loading procedures involve using cranes or forklifts to lift and position coils onto trailers or flatbed trucks. The coils are typically secured using straps, chains, or coil racks to prevent shifting during transportation. During unloading, the same equipment is used to carefully lift and remove the coils from the truck, ensuring safety and stability throughout the process.

- Q: Can you reload spent casings if they are steel?

- Steel Casings

- Q: I just bought a used Taurus 85 stainless 38 spl revolver, it's about 25 years old but looks like new. This is my first stainless steel gun. I'm wondering if there's any special things I need to be aware of or cleaning methods? I'm also wondering if stainless steel could rust? in theory stainless means it cannot get stained or rusty. I have a chrome bore AK, cleaning is always super easy, wondering of cleaning a SS revolver would be the same.

- Q: will a stainless steel gun rust? A: Under certain conditions, it can rust. But stainless steel will last longer than blued steel will under such conditions. Also, some parts of a stainless steel revolver might not be stainless steel. The internal parts may be normal steel. Q: I just bought a used Taurus 85 stainless 38 spl revolver, it's about 25 years old but looks like new. This is my first stainless steel gun. I'm wondering if there's any special things I need to be aware of or cleaning methods? A: There are no special methods required. Stainless steel is fairly convenient easy to clean and maintain. Carbon-fouling can still build-up and metal discolorations may occur. These can be cleaned up with cleaning solvents and the use of a Scotch-brite cleaning pad or something similar. If it gets a scratch, the scratch can be polished away or left alone and the scratch can become a badge of honor or something. Q: I have a chrome bore AK, cleaning is always super easy, wondering of cleaning a SS revolver would be the same. A: Stainless steel is pretty tough on its own. Chrome-lining a stainless steel barrel wouldn't be considered cost effective in most circumstances. Cleaning the inside of a stainless steel barrel will be similar to cleaning a blued steel barrel that is not chrome-lined.

- Q: hi to every one I need to konw moer about steel and iron industry (process) thank you in advance for your intresting

- Primary Steel Making first Iron ore Coke Lime stone are mined and then took to the steel plant and put in the top off a blast furnace and sinks down to the bottom off the blast furnace and turns into molten iron. Once this process has been done it is then transferred to a BOS (Basic Oxygen Steel Making) this is then poured from a ladle into the BOS and a Lance is inserted into the BOS and pure oxygen is blown into the BOS for about 30 min and turns into steel.

- Q: The steel is orangish in colour and is mostly made of copper

- Steel is an alloy of iron and carbon and optionally one or more of numerous other materials. Copper is normally not used, except sometimes in small percentages. Steel is never yellow or orange in color. Reactivity of steel depends on the materials it is alloyed with. Chromium and nickel with steel make stainless steel, which is much less prone to reactive than iron. .

- Q: How do steel coils contribute to the packaging industry?

- Steel coils are widely used in the packaging industry as they provide strength, durability, and stability to packaging materials. They are commonly used to produce metal strapping and wire, which are essential for securing and bundling goods during transportation. Additionally, steel coils are used in the production of metal cans and containers, offering a robust and reliable solution for packaging various products.

- Q: How are steel coils used in the production of wind turbines?

- Steel coils are used in the production of wind turbines to construct the tower and support structures. The coils are shaped and welded to create the tower sections, providing strength and stability to support the turbine's blades and nacelle. Additionally, the coils are also used to create the structural components, such as the base, for the turbine. Overall, steel coils play a crucial role in the manufacturing process of wind turbines, ensuring their durability and structural integrity.

- Q: How are steel coils used in the production of consumer goods?

- Steel coils are used in the production of consumer goods as raw materials for various manufacturing processes. They are often shaped, cut, or formed into different components and parts that go into products such as appliances, automobiles, furniture, and construction materials. Steel coils provide strength, durability, and versatility, making them essential in creating high-quality consumer goods.

- Q: What are the different types of steel coil handling devices?

- There are several types of steel coil handling devices, including coil lifters, coil grabs, coil tongs, coil hooks, and coil transfer cars.

Send your message to us

Hot-Dip Galvanized Steel Coil of origen of China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords