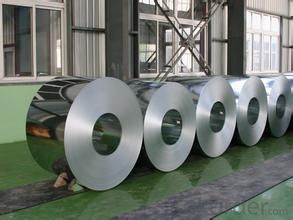

Hot-Dip Galvanized/ aluzinc Steel in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

1.Mateials:SGCC,DX51D / DX52D /S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Service:

1,on time delivery

2,high quality with competitive price

3,good service

4,long-term cooperation

5, rely on honors

Images:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

- Q: Can steel coils be coated with QR codes?

- Yes, steel coils can be coated with QR codes.

- Q: What are the environmental considerations when using steel coils?

- Some of the key environmental considerations when using steel coils include the production process, energy consumption, and the potential for waste generation. Steel production is resource-intensive and can result in high greenhouse gas emissions, contributing to climate change. Energy consumption during manufacturing and transportation should be minimized to reduce carbon footprints. Additionally, proper waste management and recycling practices should be implemented to minimize the environmental impact of steel coil usage.

- Q: How do you calculate the weight of a steel coil?

- To calculate the weight of a steel coil, you need to know its dimensions and the specific gravity of the steel. The formula to calculate the weight is as follows: Weight of steel coil = Length of coil (in meters) x Width of coil (in meters) x Thickness of coil (in meters) x Specific gravity of steel First, measure the length, width, and thickness of the steel coil in meters. Ensure that all measurements are in the same unit for accurate calculations. Next, determine the specific gravity of the steel. Specific gravity is the ratio of the density of a substance compared to the density of water. For steel, the specific gravity is typically around 7.8. Multiply the length, width, and thickness of the coil together. This will give you the volume of the steel coil in cubic meters. Finally, multiply the volume of the coil by the specific gravity of steel to obtain the weight of the steel coil in kilograms (kg). Keep in mind that this calculation provides the weight of the steel coil without considering any additional factors such as the core material or any other components included in the coil.

- Q: Hi All,I was wanting to know,on the quality bikes such as Trek,Giant etc is the aluminum frames as strong as the steel frame bikes? I have heard conflicting reports on this,so thought I would ask here for more input.Thanks!

- Someone stated even the $99 walmart bikes are aluminum now. WRONG! Most Walmart bikes have steel frames unless you drop about $200.00. Personally, I prefer aluminum over steel. It's lighter, most times - just as strong and won't rust if you get a ding or scrape in the paint. See links below on Trek M/B. Trek 820 - steel frame - $329.99. Trek 3500 - aluminum frame - $359.99.

- Q: What are the different methods of leveling steel coils?

- There are several methods of leveling steel coils, including roller leveling, stretcher leveling, and tension leveling. Roller leveling uses a series of rollers to gradually bend the steel to achieve a flat surface. Stretcher leveling involves stretching the steel through hydraulic or mechanical means to remove any residual stresses and straighten it. Tension leveling applies tension to the steel coil while passing it through a series of rollers, effectively elongating the material to remove any waviness or curvature.

- Q: But we've had a problem with bears being attracted to the water in the Intex Inflatable pools, the bear would come at night every so often and push on the sides letting out the water.Would a bear be able to bend a steel frame before I go and spend money?

- depends on the steel thickness and positioning. frm your question I'm guessing you're not really well versed in steel framing or use... im guessing whatever you build, a bear can destroy. if i was to build it not even 100 bears can destroy it. it doesn't require much steel, it's just about bracing the positing of steel and some design.

- Q: How are steel coils used in the manufacturing of springs?

- Steel coils are used in the manufacturing of springs by being wound and coiled into a helical shape, providing the necessary strength and flexibility to the springs.

- Q: I just want regular steel, not stainless steel.

- Iron is the primary ingredient in steel. All Steel is an alloy by definition. Stainless steels are alloys that resist corrosion. There are dozens of alloys of steel. Many stainless steels are not magnetic. If a magnet won't stick to it it is very likely to be a stainless steel but that is not true for all stainless steels. You really do need to be more specific as to what you want and why. There are too many to chose from.

- Q: What are the common defects in steel coil finishes?

- There are several common defects that can occur in steel coil finishes. These defects can impact the appearance and functionality of the steel and may need to be addressed before the coil can be used or sold. 1. Coil breaks: Coil breaks are a common defect where the steel strip breaks during winding or unwinding. This defect can result in a discontinuity in the surface of the coil and can lead to further damage if not addressed. 2. Edge wave: Edge wave refers to a distortion or waviness at the edges of the steel coil. This defect can occur during the rolling or cooling process and can affect the flatness and uniformity of the coil. 3. Corrosion: Corrosion can occur on the surface of steel coils if they are not properly protected or stored. This can lead to rust and degradation of the steel, impacting its strength and appearance. 4. Streaks and stains: Streaks and stains can occur on the surface of steel coils due to improper cleaning or contamination during the production process. These defects can affect the aesthetic appearance of the steel and may need to be addressed before the coil can be used. 5. Scratches and dents: Scratches and dents can occur on the surface of steel coils during handling, transportation, or storage. These defects can impact the flatness and surface quality of the steel and may require repairs or adjustments. 6. Coating defects: If the steel coil has a coating or paint applied to it, several defects can occur. These include blistering, peeling, or uneven application of the coating, which can affect the durability and appearance of the steel. It is important to note that these defects can vary in severity and may require different methods of repair or mitigation. Regular inspections and quality control measures can help identify and address these defects before they become more significant issues.

- Q: What is the standard diameter of steel coils?

- Depending on the industry and application, the standard diameter of steel coils may differ. Generally, steel coils have a standard diameter that falls between 24 inches and 72 inches. This range enables convenient handling, transportation, and storage of the coils. It is worth mentioning that various industries may impose specific requirements for steel coil diameters, taking into account factors like equipment compatibility, production processes, and logistical considerations.

Send your message to us

Hot-Dip Galvanized/ aluzinc Steel in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords