Galvanized Iron Wire In Coil With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

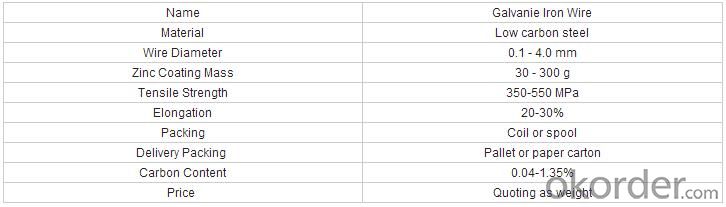

Specification

Material:

Galvanized Iron Wire

Cross Sectional Shape:

Round

Application:

Construction Wire Mesh

Type:

Galvanized

Wild in Width:

1.1M

Surface Treatment:

galvanized

Metal Wire Drawing:

Cold Drawing

Status:

In Hard State

Thickness:

Metal Thick Wire

Galvanized Technique:

Hot Dipped Galvanized,Electro Galvanized

Product description

Material: High quality low carbon steel

Processing And Character: Have been gone through the process of wire drawing, acid washing, rust removing, annealing and coiling, it offers excellent flexibility and softness.

Usage: Used in weaving wire mesh, construction, handicrafts, express way fencing mesh, packaging of products and other daily uses.

Specification: Hot dipped galvanized iron wire, BWG24-BWG8; Electric galvanized iron wire: BWG36-BWG8

Product show

Galvanized wire | |||||||

| Wire gauge size | SWG | BWG | |||||

| Inch | mm | Inch | mm | ||||

| 8 | 0.160 | 4.06 | 0.165 | 4.19 | |||

| 9 | 0.144 | 3.66 | 0.148 | 3.76 | |||

| 10 | 0.128 | 3.25 | 0.134 | 3.40 | |||

| 11 | 0.116 | 2.95 | 0.120 | 3.05 | |||

| 12 | 0.104 | 2.64 | 0.109 | 2.77 | |||

| 13 | 0.092 | 2.34 | 0.095 | 2.41 | |||

| 14 | 0.080 | 2.03 | 0.083 | 2.11 | |||

| 15 | 0.072 | 1.83 | 0.072 | 1.83 | |||

| 16 | 0.064 | 1.63 | 0.065 | 1.65 | |||

| 17 | 0.056 | 1.42 | 0.058 | 1.47 | |||

| 18 | 0.048 | 1.22 | 0.049 | 1.25 | |||

| 19 | 0.040 | 1.02 | 0.042 | 1.07 | |||

| 20 | 0.036 | 0.91 | 0.035 | 0.89 | |||

| 21 | 0.032 | 0.81 | 0.032 | 0.813 | |||

| 22 | 0.028 | 0.71 | 0.028 | 0.711 | |||

| 23 | 0.024 | 0.61 | 0.025 | 0.64 | |||

| 24 | 0.022 | 0.56 | 0.022 | 0.56 | |||

| 25 | 0.02 | 0.51 | 0.020 | 0.51 | |||

| 26 | 0.018 | 0.46 | 0.018 | 0.46 | |||

| 27 | 0.016 | 0.42 | 0.016 | 0.41 | |||

| 28 | 0.015 | 0.38 | 0.014 | 0.36 | |||

| 29 | 0.014 | 0.35 | 0.013 | 0.33 | |||

| 30 | 0.0124 | 0.32 | 0.012 | 0.31 | |||

| 31 | 0.012. | 0.30 | 0.010 | 0.25 | |||

| 32 | 0.011 | 0.27 | 0.009 | 0.23 | |||

| 33 | 0.010 | 0.25 | 0.008 | 0.20 | |||

| 34 | 0.009 | 0.23 | 0.007 | 0.18 | |||

| 35 | 0.008 | 0.21 | 0.005 | 0.13 | |||

| 36 | 0.0076 | 0.19 | 0.004 | 0.10 | |||

| 37 | 0.07 | 0.17 | |||||

| 38 | 0.006 | 0.15 | |||||

- Q: my radio was stolen i'm trying to put in a old radio in but when someone stoled my radio they cut the wires so now i can't tell what go,s where can someone please help? it's a ford f150 pu trck w/ 4 speakers i just need the wire color codes to hook-up,plus thy stole the manal to the trck too. please help.ty

- who needs manuals. u should kno which is ur power and anteanna stuff if its just the speaker wires.. then simply touch them to each other and if it makes sound. then u have sound:)

- Q: When was the hot-wire anemometer invented? and who was it?

- Sir Charles Wheatstone in 1843 modern anemometer use ultrasound hot wire sensors are used as mass air flow but did not find original usage! Guru

- Q: ok so i have 3 questions.i have an oldsmobile cuttlas supreme and i have a 0 gauge power wire that is 17 feet is that long enough???? and i have 0 gauge ground that is 17 feet is that long enough....and about the speaker wire..i have 8 gauge speaker wire that is 25 feet..is this a good setup.make sure u answer all these questions please thank you..

- the 17 ft of power wire is going to be fine. Just make sure you install an inline fuse by the battery. The 17ft of ground wire is a little bit too much, but you can cut that down. Make sure you ground the amp as close as possible so the voltage drop is minimal. The 8 guage speaker wire is way too high a gauge for speaker wire. You would be fine with 12, 14, or 16 gauge. The length needed depends on what speakers you plan to wire up. If its just subs then I would say thats more than enough. If you're powering components, you will need much more, probable close to 100. Overall it should be a good setup though.

- Q: The wire from the cicuit breaker

- 8 guage if it's 220v

- Q: the plug only has room for black,red,ground wire.. what do i do with the white wire

- You can't. You need a 4-wire receptacle to use with 4-wire cable. That is the only to wire this circuit to code. You will need to replace the cord on your appliance with a 4-wire as well.

- Q: do you match positives and negatives or positives and positives when wiring a car stereo

- This Site Might Help You. RE: color code for wires in a 2000 ford explorer? do you match positives and negatives or positives and positives when wiring a car stereo

- Q: What do all the wires do

- Constant 12V+Orange Switched 12V+Yellow GroundBlack IlluminationGray DimmerBrown Antenna TriggerPink AntennaRight Rear Front Speakers5 1/4 Dash Left Front (+)Tan Left Front (-)Gray Right Front (+)Light Green Right Front (-)Dark Green Rear Speakers6 x 9 Rear Deck Left Rear (+)Brown Left Rear (-)Yellow Right Rear (+)Dark Blue Right Rear (-)Light Blue

- Q: Does anyone know where i can buy them? I need new ones because my crazy cat chewed up two of the wires lol =#92;

- Hey there, That is unfortunate and I am quite sure that catfood is cheaper than speak cables these days. What you are looking for is standard speaker cables found in most sorted retailers. Try your local supermarket or electronics store.

- Q: Two steel wires are stretched with the same tension. The first wire has a diameter of 6.00E-4 m and the second wire has a diameter of 8.90E-4 m. If the speed of waves traveling along the first wire is 53.2 m/s, what is the speed of waves traveling along the second wire?

- Wave velocity v = √(T/μ) Same tension in both wires: T1 = T2 μ is the linear mass density v1 = 53.2 m/s v2 = ? = v1/v2 = √(T1/μ1) / √(T2/μ2) = √(T1μ2 / T2μ1) = √(T1/T2 * μ2/μ1) = √(μ2/μ1) Linear mass density is mass/length, mass is density*volume: m/L = ρV/L = ρAL/L = ρA = ρπr^2 Both wires are steel so their density is the same. == v1/v2 = √(μ2/μ1) = √(ρπr2^2 / ρπr1^2) = √(r2^2 / r1^2) = r2/r1 == v2 = v1r1/r2 = (53.2*3.00×10^-4) / 4.45×10^-4 = 35.9 m/s ---- Speed of waves along the second wire is 35.9 m/s

- Q: I'm installing a remote start system in my car, but I can't find the tach wire. Does anyone know what harness it is located in, and what color the cable is? I've looked over the diagrams, but I can't seem to find the cable that runs to the tach guage.

- Tachometer blue wire AC under the distributor or side

Send your message to us

Galvanized Iron Wire In Coil With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches