Galvanized Corrugated Steel Sheet in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip GI/GL Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip GI/GL Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

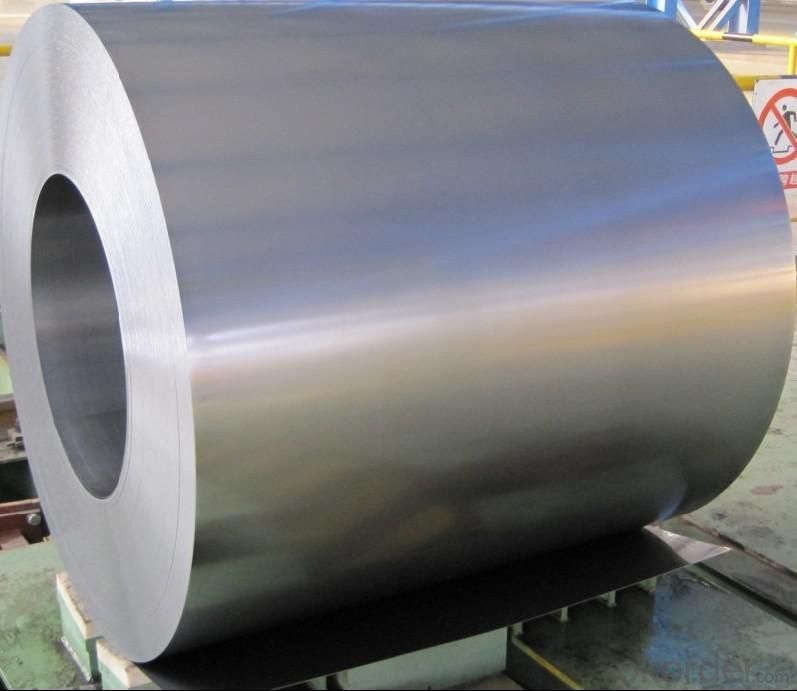

3.Hot-Dip GI/GL Steel Sheet Images:

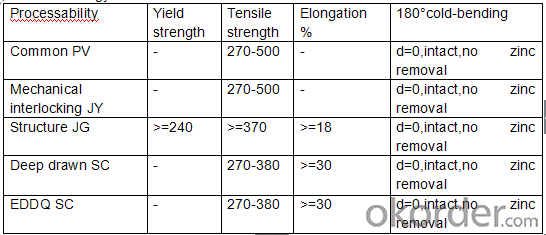

4.Hot-Dip GI/GL Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

5.FAQ of Hot-Dip GI/GL Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What is the price range of steel sheets?

- The cost of steel sheets can differ based on various factors, including the steel's type and grade, the sheet's thickness and size, and the prevailing market conditions. Typically, steel sheets can be priced between $0.60 and $1.50 per pound. Nevertheless, it is crucial to note that these figures are only approximate and subject to frequent modifications due to fluctuations in the steel market and other economic elements. To obtain the most precise and current pricing details for steel sheets, it is recommended to consult local suppliers or utilize online platforms.

- Q: What are the load-bearing capacities of steel sheets?

- The load-bearing capacities of steel sheets can vary depending on factors such as the thickness, grade, and type of steel used. Generally, steel sheets can have high load-bearing capacities due to their inherent strength and durability. However, it is crucial to consult engineering specifications and professional advice to determine the precise load-bearing capacity for specific steel sheets in different applications.

- Q: How do steel sheets perform in terms of corrosion resistance?

- Steel sheets possess good corrosion resistance in general, particularly when they are coated with protective layers like zinc or alloys. The corrosion resistance of steel sheets relies on the steel's composition and quality, as well as the environment in which they are employed. Stainless steel sheets, for instance, demonstrate remarkable resistance against corrosion due to the presence of chromium and other alloying elements. These sheets prove highly effective in environments with elevated humidity, exposure to saltwater, or acidic conditions. However, in aggressive environments, uncoated or low-alloy steel sheets may be vulnerable to rust and corrosion. Regular maintenance, such as the application of protective coatings or the use of corrosion inhibitors, can enhance the corrosion resistance of steel sheets and extend their lifespan.

- Q: What are the different sheet metal cutting techniques for steel sheets?

- There are several different sheet metal cutting techniques that can be used specifically for steel sheets. Here are some commonly used methods: 1. Shearing: This is a traditional method where a shear or a pair of blades is used to cut the steel sheet by applying a high force. It is ideal for straight cuts and can be used for both thin and thick steel sheets. 2. Laser cutting: This technique uses a high-powered laser beam to cut through the steel sheet. It offers high precision and can create intricate designs. Laser cutting is suitable for both thin and thick steel sheets. 3. Plasma cutting: Plasma cutting involves the use of a plasma torch that generates an electrically conductive jet of plasma to cut through the steel. It is commonly used for thick steel sheets and offers fast cutting speeds. 4. Waterjet cutting: In this method, a high-pressure jet of water mixed with abrasive particles is used to cut through the steel sheet. Waterjet cutting is versatile and can handle various thicknesses of steel sheets. It is also suitable for cutting heat-sensitive materials. 5. Punching: Punching involves using a punch and die set to create holes or other shapes in the steel sheet. It is a cost-effective method for repetitive cuts and can be used for both thin and thick steel sheets. 6. Abrasive cutting: This technique uses an abrasive wheel or disc to grind through the steel sheet. It is typically used for thin steel sheets and provides a smooth finish. The choice of cutting technique depends on factors such as the thickness of the steel sheet, required precision, complexity of the design, and the material's heat sensitivity. Each technique has its advantages and limitations, so it is important to consider these factors when selecting the appropriate method for cutting steel sheets.

- Q: What are the different surface textures for galvanized steel sheets?

- There are several different surface textures available for galvanized steel sheets, including smooth, diamond-patterned, and textured.

- Q: What are the different finishes available for steel sheets?

- There are several different finishes available for steel sheets, including hot rolled, cold rolled, galvanized, and stainless steel finishes.

- Q: Can steel sheets be used in the construction of bridges?

- Yes, steel sheets can be used in the construction of bridges. Steel is a commonly used material in bridge construction due to its many advantageous properties. Steel sheets provide high strength and durability, making them suitable for withstanding heavy loads and harsh weather conditions. They are also flexible, allowing for easier fabrication and installation. Additionally, steel sheets can be easily joined together using welding or bolting, making them ideal for constructing large structures like bridges. Overall, steel sheets offer a cost-effective and reliable solution for bridge construction.

- Q: What is the maximum length of steel sheets?

- The maximum length of steel sheets varies depending on the manufacturer and specific product, but it can typically range from 12 to 40 feet.

- Q: What are the different sheet metal stamping techniques for steel sheets?

- There are several sheet metal stamping techniques for steel sheets, including blanking, piercing, bending, deep drawing, and embossing.

- Q: What is the cost of steel sheets compared to other materials?

- The cost of steel sheets typically varies depending on factors such as size, thickness, and specific type of steel. However, in general, steel sheets tend to be more affordable compared to other materials such as aluminum or titanium.

Send your message to us

Galvanized Corrugated Steel Sheet in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords