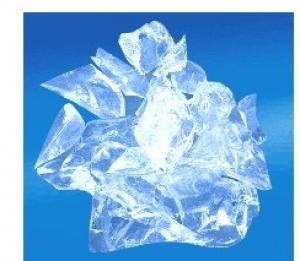

Raw Materials for Refractory - Fused Silica 1-3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT INFORMATION | |

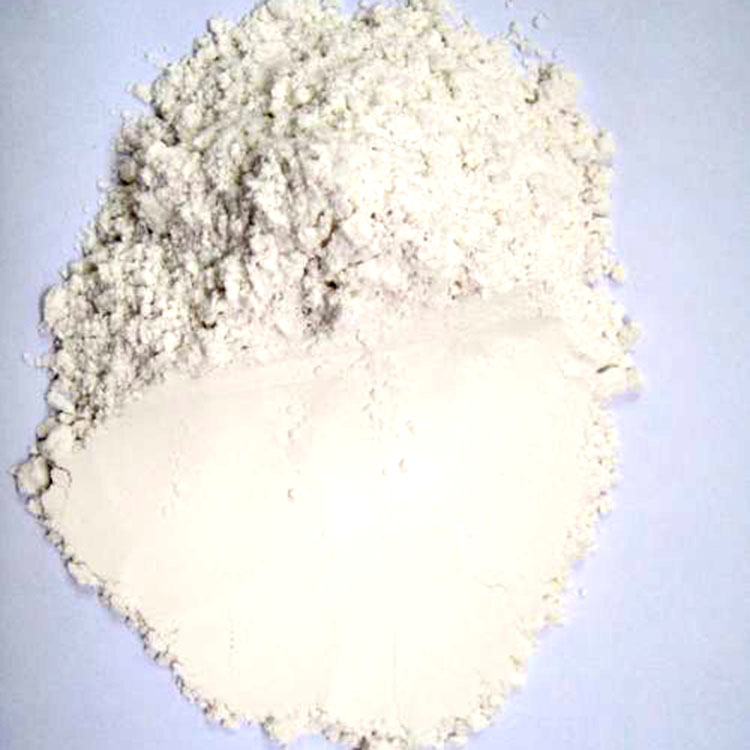

Item | Fused Silica Powder |

Size | D50=9~11um |

Application | Epoxy insulation encapsulant material / Epoxy Molding Compound (EMC), Copper Clad Laminate (CCL), Electromagnetism Industry, Electronic Industry, Ceramic Industry, The Aerospace Industry, Glass Industry, Plastics Industry, Grinding Material Industry, Coating Industry, Investment Casting Industry, Thermal Insulation Product of Calcium Silicate, Refractory Material |

Model No. | R610 |

MOQ | 5 ton |

Material | natural silica rock after melting |

H.S. CODE | 25061000 |

PRODUCT CHEMICAL COMPOSITION AND PHYSICAL PROPERTIES | |

SiO2 | >99.99% |

Al2O3 | <0.015% 1000ppm |

Fe2O3 | <0.002% 50ppm |

Density | 2.2 |

Whiteness | >92% |

Moisture content | <0.05% |

Mohs hardness | 6.5 |

Igniting loss | <0.12% |

Appearance | powder |

- Q: What are unshaped fire-resisitance materials?

- Refractory castable, refractory plastic material, usually classified according to construction and manufacture method, unfired bricks precast block, refractory pressed into material, refractory cast material, refractory coating, refractory ramming material there are many classification methods

- Q: I wanna ask about the building insulation materials fire rating?

- Hello, I am happy to answer your questions about the classification of building insulation materials fire rating: 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3 combustion performance is level B2 insulation material: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. I hope I can help you

- Q: How long is the fire resistant limit for ultra thin fire retardant coating?

- According to the "code for fire protection design of tall buildings", the fire resistance time of the component is at the first level: 3 hours, beam: 2 hours, floor: 1.5 hours;if fire resistance level is level 2, the requirement for time of fire resistance component is the column: 2.5 hours, beam: 1.5 hours, floor: 1 hours. For fire resistant coating, fire resistance time for ultra-thin fire retardant coating is less than 1.5 hours. If the time exceeds 1.5 hours, thick fire resistive coating should be uesd.

- Q: Is the ball mill used in production of refractories?

- It will be used. It is used in the process of milling the raw material which is less demanding on technology and in relatively large amount. Is there lots of network marketing for refractory industry? Is the competition fierce on the Internet?

- Q: What material is refractory material?

- Basic refractory materials, basic refractory, CaO, basic, MgO style alkaline earth oxide. The refractory materials mainly refers to magnesia refractories, dolomitic and lime refractory refractory. Main categories: (1) strongly basic magnesite brick, magnesia carbon brick, limestone and dolomite brick refractory materials;(2) alkalescent magnesia chrome refractories, forsterite refractory, magnalium and magnesia-chrome spinel refractory, basic refractory materials, high-temperature caustic slag, alkaline solvent resistance, strongly acidic slag flux or acidic refractory. The reaction is mainly used in steel furnace such as colour metal smelting furnace and cement kiln.

- Q: The development prospect of fire-resistant material

- Exported bulk material amounts to exported raw material/ To protect domestic resources, many countries have set linitations on the magnesium content in shapeless refractory material and lisences.

- Q: What is the most reasonable drying heating curve of magnesia refractories? Products of less than 0.5T

- The material is very troublesome, it might crack horrendously if not baked well and all of them may be scraps after being took out from the furnace. Magnesia hydration is inevitable during the baking process. As volume expansibility of magnesite reaches 200%, so it is easy to crack. The key to bake is to quickly rule out the water vapor in furnace, especially within 150 degrees Celsius. After quickly ruling out the water vapor in furnace to avoid excessive reaction with magnesia of 150 degrees, it can be operated in accordance with convention. In addition, you should pay attention to the heat sources, for which i recommend electrical and coke to avoid generating a lot of water vapor during the natural gas combustion process which will worsen the situation.

- Q: What is the main material of fireproof wooden door?

- Fireproof door is an important part of fire-fighting apparatus and society fire prevention, so the quality and use of fireproof door is the key to the success of the fire prevention. Some customers don't know clearly that whether the fireproof door should install a door closer. Today I specially read the explanation of relevant state departments for fireproof door, in the explanation in 5.3.3, fireproof door should be installed fireproof door closer or set, so that normally open fireproof door can automatically close close-door device of the door leaf (except for the use of special parts, such as pipe shaft doors, etc.) in the event of a fire. In other words, except for some special parts which don't need to be installed door?closer, such as pipe shaft doors, other parts are required to install fireproof door closer.

- Q: How to choose the material of refractory?

- Long using temperature of aluminum oxide fiber is 1400 ℃, containing chromium aluminum silicate fiber, quartz, high purity aluminum silicate fiber, long-term use of temperature is 1000-1200 ℃ has aluminum silicate refractory fiber according to different raw materials, advanced refractory fiber (such as alumina. Commonly used vitreous aluminum silicate refractory fibre is amorphous, zirconium oxide refractory fibre) using temperature is 1700 ℃ view as >and the best temperature is 1300 ℃. Crystalline refractory fiber are polycrystalline mullite fiber, including ordinary aluminum silicate fiber, alumina and graphite refractory fiber, etc. The use of common refractory fiber temperature is 1150 ℃;>

Send your message to us

Raw Materials for Refractory - Fused Silica 1-3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords