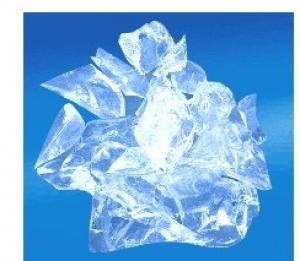

Raw Materials for Refractory - Fused Silica

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT INFORMATION | |

Item | Fused Silica Powder |

Size | D50=9~11um |

Application | Epoxy insulation encapsulant material / Epoxy Molding Compound (EMC), Copper Clad Laminate (CCL), Electromagnetism Industry, Electronic Industry, Ceramic Industry, The Aerospace Industry, Glass Industry, Plastics Industry, Grinding Material Industry, Coating Industry, Investment Casting Industry, Thermal Insulation Product of Calcium Silicate, Refractory Material |

Model No. | R610 |

MOQ | 5 ton |

Material | natural silica rock after melting |

H.S. CODE | 25061000 |

PRODUCT CHEMICAL COMPOSITION AND PHYSICAL PROPERTIES | |

SiO2 | >99.99% |

Al2O3 | <0.015% 1000ppm |

Fe2O3 | <0.002% 50ppm |

Density | 2.2 |

Whiteness | >92% |

Moisture content | <0.05% |

Mohs hardness | 6.5 |

Igniting loss | <0.12% |

Appearance | powder |

- Q: What are the materials of white firebricks?

- White refractory materials are generally divided into two types, namely, unshaped refractory materials and shaped refractory materials. Unshaped refractory materials, also called castables, is a mix of powdery particles of many aggregates and one or multiple adhesives. They must be stirred well with one or multiple liquids when in use, which has a strong liquidity. Unshaped refractory materials generally refers to firebricks. They have standard rules about their shapes and can also be processed temporarily as needed.

- Q: Does anyone know the refractory temperature of fire-resistant glass?

- Ordinary glass will burst under sharp temperature difference of about 70-120 degrees and toughened glass of 200 degrees. It is not yet clear for the bursting temperature differences of the refractory glass. If the overall glass is heated evenly, it will have no significant change below 600 degrees, and it will deform with the increase of temperature until melting. The fire-resistant time of the glass you said is the time to heat the glass into the extreme temperature differences it can endure, which should not be more than 10 minutes

- Q: Is refractory material harmful to human body?

- Chromium oxide is poisonous in alkaline environment, and the gas produced by heating of asphalt, asphalt and refractory material is poisonous............ Go to the real estate company experts, I can think of these

- Q: Is there vermiculite in refractory?

- Vermiculite is usually used as lightweight material in refractory field, and its volume density is about 0.5.

- Q: What's the heat conductivity coefficient of fire-resistant material?

- 5~5 (Unit: W·m-1·K-1). The symbols are λ or K. Thermal conductivity and material properties Thermal insulation material generally is 0, and is related to organizational structure and working temperature. Thermal conductivity of the material refers to the heat transferred from from one plane to another plane in 1 seconds. Generally the thermal conductivity of fire-resistant material is 1. The larger the value is, the stronger the thermal conduction performance is. If the temperature of two planses differes for 1K, then the thermal conductivity is 03~1. The plane cover 1square meter.

- Q: How is refractory material made?

- It is made from carbon materials.

- Q: What is the difference between the fire?rating and the fire resistant level of the fire-fighting equipment?

- Fire rating and fire-fighting rating are the misnomer to the building fire resistant level. The building fire risk is measured by fire resistant level. The article 3.2.1 and 5.1.7 of "Architectural design code for fire protection" have made provision respectively on the fire resistant level of plant (the storeroom) and civil construction. Article 3.0.2 of "Code for fire protection design of tall buildings" has made provisions on the fire resistant level of tall buildings. As for the warehouse building "category malonate", it refers to one of the fire risk of goods storage, which is divided into A, B, C, D, E, and each category is refined depending on the nature of different substances. "Malonate class" specified in article 3.1.3 of "building design for fire protection" refers to the flammable solid.

- Q: What 's the highest temperature can magnesium plate glass resist ?

- Glass magnesium plate is non combustible plate having good fire-resisitance quality. Flame will never burn continuously on it. It does not catch on fire when temperature reach 800 ℃, and will not be lit up at 1200 ℃. The plate, having high-quality keel partition system, is rated as the highest non-combustible level A1 with fire resistance being above 3 hours. It absorbs a lot of heat when fire is burning, delaying rise of ambient temperature.

- Q: Firing high temperature kiln of refractory and internal temperature being as high as 1600 ℃, metal heat exchanger can't use, how to do?

- Directly using silicon molybdenum kiln, the temperature is better. Now using the electricity is cheaper than the price of other fuels.

- Q: I am a refractory material manufacturer, sold products, money is always not back, anxious to die, what is the way?

- Many manufacturers are facing the same problem, difficult to find the order, order the payment contract is more difficult, it is difficult to have binding, the better solution is to seek third party secured transactions, see the whole production or see full delivery

Send your message to us

Raw Materials for Refractory - Fused Silica

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords