Flex Banner

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meter m²

- Supply Capability:

- 20 Container Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

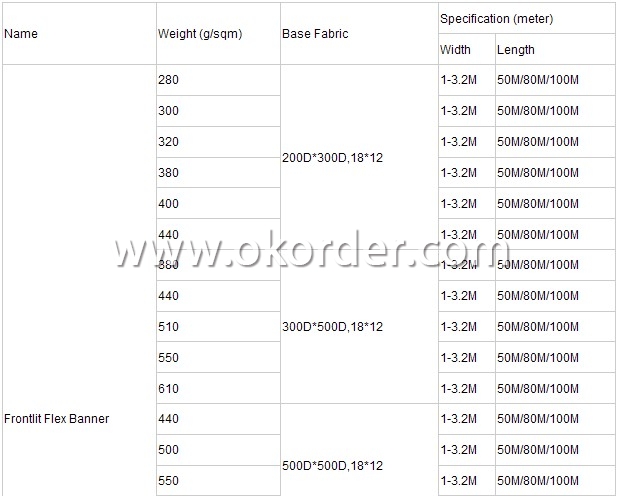

5m wide 200D*300D,300D*500D PVC flex banner, with solvent&eco-solvent ink, excellent printing quality, featured with

1. Anti flame available (FR B1, B2 grade)

2. White substrate for wide format digital printing

3. Pure white translucent substrates for frontlit/backlit displays

Typical specification of flex banner:

Application of flex banner:

1. Large format light boxes

2. Displays (indoor and outdoor)

3. Airport light boxes

4. Exhibition booth decoration

- Q: Do you need a cushion on the ground floor?

- As well as the time to build a wooden building with concrete pier, from the ground or contact the ground to do a good job preserving.

- Q: The cushion is usually in the housing which parts

- Cushion is generally at the base, looking for the use.

- Q: Do you need a cushion for roof waterproofing?

- If the base layer of the waterproof layer is flat or in line with the requirements of the waterproof material process, you can not do leveling layer. For example, in the cast-in-place concrete roof with the pound with wiping light, may serve as the waterproof layer of the grassroots.

- Q: Why do the basics of the cushion waterproofing

- Base cushion waterproofing is not contact with the soil (Ying water) to prevent water into the cushion, but in the cushion and the base of the bottom of the contact, in fact, is the basis of the bottom of the waterproof.

- Q: Is the raft cushion waterproofing full of the cushion?

- Assuming (just suppose) the raft can easily turn over, then we do waterproof (like roof) directly on it, not waterproof on the cushion.

- Q: Cushion, waterproof layer construction to do what information

- 1, the cushion to do template inspection batch information. Waterproof to do waterproof shelter, waterproof inspection batch, waterproof detail structure.

- Q: What is the relationship between the cushion and the ring beam?

- Cushion is plain concrete or asphalt concrete (for groundwater soil corrosive strong site). Is located below the ground, in order to prevent the foundation or the concrete beam pouring when the excessive loss of water caused by defects set. The purpose is to ensure the quality of concrete, increase the durability of underground components

- Q: Large area ground concrete cushion seam Why is the separation of joints generally concrete

- First, the rigid waterproof layer in a large area of ??construction, by the external force, temperature, humidity changes, structural layer deformation and other factors prone to cracking, leading to leakage, the design should consider the deformation of the waterproof layer to take the necessary Structural or structural measures to avoid and mitigate the cracking of the waterproofing layer to achieve the desired waterproofing effect.

- Q: Basement floor mattress dry to what degree can do coil waterproof?

- Second, when the design of the highest groundwater level above the bottom of the basement floor, you must do waterproofing. As the waterproof waterproof effect is good, so the application of more. Internal waterproofing is generally used for repair works.

- Q: Why calculate the amount of time to count a lot of cushion ah

- Cushion cushion, as the name suggests is the structure of the liner layer, mainly from the back cover of the role, generally in the engineering design drawings have a clear approach (material).

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 30% South America 20% Southeast Asia 20% Africa 10% Mid East 10% Eastern Asia 10% Central America |

| Company Certifications | ISO 9001:2008;CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | Above10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Flex Banner

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meter m²

- Supply Capability:

- 20 Container Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords