Ceramic Fiber Blanket - Fireproof Material for Fireplace Resilient to Thermal Shock

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Material for Fireplace Resilient to Thermal Shock

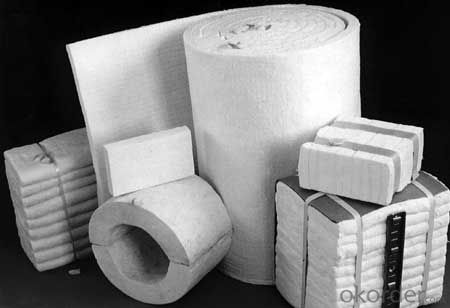

Description for ceramic fiber fireproof material for fireplace

Ceramic fiber is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Ceramic fiber has a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of ceramic fiber also has difference,and they are suitable for different workong temperatures.

Ceramic fiber can be used after optional cutting .When ceramic fiber storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

Features for fireproof material for fireplace

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Advandage for fireproof material for fireplace

◆High-purity type

◆High-temperature refractory

◆Al Content (%): 32-55

◆Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

◆Density: 64-160kg/m3

◆Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

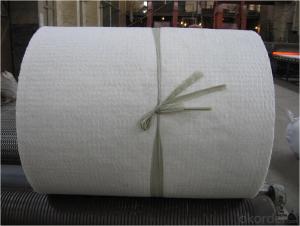

Images for fireproof material for fireplace

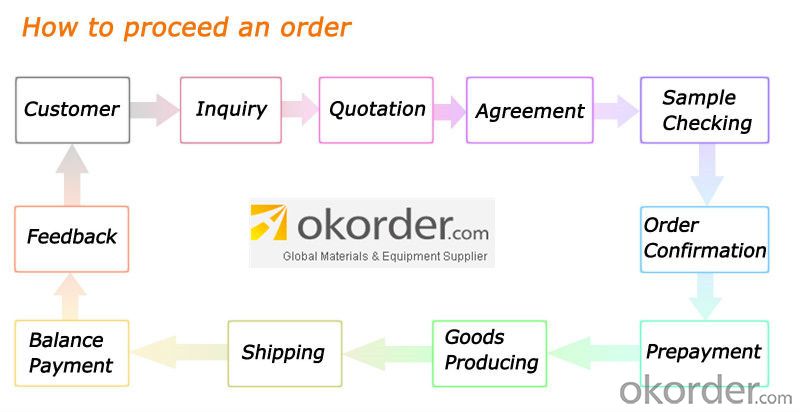

◆Product Process for fireproof material for fireplace

◆Packaging

FAQ

Can we accept OEM for fireproof material for fire place

?

YES! We can according your demand to produce.

Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us,okorder will provide our best products and services for you!!

- Q: my hairs are very curly so i m planning for straitening hw straitening helps.what are the maintainance, advantages , disadvantages of straitening of hairshelp me

- Your question is a little vagueYou are not clear as to which straightening method you are planning to do, flat iron or chemicalAt any rate, neither method will affect the hair rootsChemical hair straighteners can cause your hair to be dry because the products used to straighten hair are high alkalineIf you use a flat iron, always use a thermal protectant on your hair and never use a flat iron on damp or wet hairThe original CHI Ceramic flat iron is the one I use and Framesi Options WIO Straight Balm is the thermal protectant I use on my hair and my customersGet regular trims to prevent spits ends and this applies to every oneRegular trims is the key to having healthy hairHope this is of some help.

- Q: would aluminum foil backed foam board insulation reflect or retain heat or cool back into my house?

- Hire a home inspector to look at your problemThere could be many causes, such as someone removed a supporting wall down the middle of the home, or you could have a leak in the roof allowing water to enter and collect above - one day to come raining down on youMaybe the wrong sized joist were usedThe list could go on and onSpend a couple bucks and find out the real problem and go from there.

- Q: I have 2 bedrooms upstairs in a cape cod style homeThere is a kick wall on both sides of each bedroom that is accessible for storageWhat is the best way to add insulation inside the storage areas without pulling up floor boards.

- makes a few burnt bored toast, a great scorching cup of bored teaStick on a run of the mill video, stroke the bored cat then hop upstairs in your bored mattress and get a few great bored close-eyeYou wont be bored in case your asleep.

- Q: ok, so right now i have really high quality liquid cover up and power foundationi try to cover up left over pimples that are still there after my acne treatmentit never fully covers it up, and when it does, it has a completely different skin tone than the rest of my face because i have to cake it on there! and it eventually comes off durring the day anywayshow can i cover up unwanted blemishes?

- Hillbill is absolutely correctI have done this many, many times and have never had a problemThe Armor-all tip he mentioned is also correct, I do that too and you would not believe how it will make your engine compartment look.

- Q: I have a hot water boiler to heat my old houseI have insulated the pipes in the crawl space and only the roof in insulated (not walls or the crawl space) its around 15F right now, i have my heater at 60F because i honestly cant afford to keep it any higher, plus my girlfriend loves it cold when shes asleep (canadian)Sense some of boiler pipes are next to the reghot and cold pipes (by next to i mean a few feet away) will the boiler pipes keep the pipes warm unuff to prevent freezing in the crawl space? Basically do my pipes run a risk of freezing at this moment? An how good does pipe insulation really work? I insulated with 3/4in an on the corners i sprayed foam insulationThanks in advance!

- You say the youngsters' litter box is small with small edgesHave you tried using a cake pan size litter box ( or even use a cake pan )? These are only 2 tall, so a kitten doesn't have to climb in.Maybe, that would work better for that one who doesn't like to climb? Climbing onto a sofa is NOT the same as trying to get over the lip of a boxThe kittens use their claws to climb on furnitureOnce the kittens get a little bigger, you can go back to the box you're using nowAs for the carpet, you can get a plastic place mat and set it in front of the box.or a few so that you can cover all sides.much easier to wipe off than clean the carpet! Hope this helps.Good luck.

- Q: As in local stores not websites.

- Because hemp is a natural fiber most users will dye it themselvesYou could try a custom yarn shopI assume your referring to a yarn and not a fabricHey, check out the link, they have itOh sorry, just realized you did not want webSo back to custom yarnsGood luck

- Q: 1) What are the sound, acoustic, noise insulation technical specifications and codes?2) Where can I find method statements, formulations and calculations for acoustic insulation?3) What are the best three software for acoustic insulation calculations and design?thanks

- your asking way too much from YAyou have a lot of research ahead of you.

- Q: sum1 said its possible to mix jello packet with water n drink it before a pee test to pass?is it true

- The Rights-Less Panty Wastes-Micheal Moore

- Q: Why should we eat less:Fat, Sugar and Water and eat more fibreWhere do we find Fat, Sugar and Water and Fibre (in food)? and do you know any healthy alternatives? egsugar - diet coke :)

- On attic fans-we used to have one, and they are greatIf the old one is in the attic, you might be able to get an electrician to replace the motorBut you know to use it, you have to open lots of windows, right? Then it pulls in the air, making it chilly even in the heat of the summerBut it is loudOurs had the louver section in a central hallway, with the switch to turn it on nearbyOurs in the attic had some kind of papery (like cardboard) thing tenting the louvers as wellI don't think they are all that complicated, but you'd have to find the specifications to put one togetherA HVAC guy would probably not know anything about them I think the price probably would run a couple hundred at the most for the fan, installation a couple of hours of an electrician or handyman's timeBut I do not know if they are even still made, as they are considered pretty obsolete.

- Q: There are some root rats in my attic and I wonder how to get rid of the rats.What is the best way to deal with those rats?Can I manage it by myself or should I hire a professional or rodent control guy to do this job?I heard the rat traps from Home Depot or Walmart may work.What are the tips to set up those traps correctly so that they will work efficiently?If use traps, how many should I put in the attic? need to put in the whole attic? or just a few spots?what is the best bait to use in the traps?Eventually how can I know if all the rats have been killed or left my attic?How long should I wait before I seal any potential openings?Looking forward to any suggestions and advises.Thanks.

- Foil would be cheaper.however I could see a screen giving you more air flow.

Send your message to us

Ceramic Fiber Blanket - Fireproof Material for Fireplace Resilient to Thermal Shock

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords