Fireclay Brick - China Made Good Thermal Shock Resistance for Furnaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

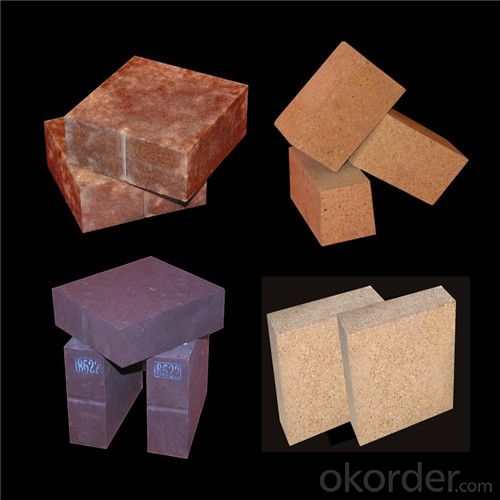

Type:

We can supply High Alumina Bricks, Fireclay Bricks, Low Porosity Fireclay Bricks, Mullite Bricks, Corundum Bricks, AZS Bricks, Magnesite Bricks, Zircon Bricks,insulating Bricks etc.

Application:

Andalusite bricks are mainly used in the cooling wall of blast furnace, chemical and ceramic industry, the door of coke oven, or as the lining and checker of hot blast furnaces.

Specification:

Fireclay refractory brick

Product Index | N-1 | JN-40 | JN-42 | |

Al2O3 % | ≥42 | ≥40 | ≥42 | |

Fe2O3 % | ≤2.3 | ≤2.4 | ≤2.5 | |

Refractoriness °C | 1760 | 1760 | 1760 | |

Bulk density g/cm3 | 2.10 | 2.12 | 2.10 | |

Apparent porosity % | ≤22 | ≤24 | ≤23 | |

Refractoriness under load 0.2MPa°C | 1400 | 1380 | 1450 | |

Cold crushing strength MPa | 35 | 30 | 35 | |

Permanent linear chang % | 1500°C×2h | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 |

FAQ

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: Is the diameter of 2.5 meters of the calcium aluminate powder rotary kiln referred to the inner diameter of the refractory brick?

- No, it should be outer diameter.

- Q: What kind of coal should be used to burn refractory brick? and how many calories smoke is suitable?

- It can't be the surface of coal, at least it is coal seed.

- Q: what effect does big mortar joints of the boiler refractory brick have on the boiler?

- The ventilation leakage。 Now the larger boilers are generally used refractory pouring material one-time pouring, the arch is easy to collapse . 2, shrinkage and expansion of brick will make the bricks fall. 1, do not use the refractory brick. too large seam will effect the tightness of furnace wall , and the water wall is easy to form dew and be corroded and to leak smoke.

- Q: What are the materials for building blocks and what are the specifications?

- Material: clay brick, shale, coal gangue brick, fly ash brick, lime sand brick, concrete brick etc..

- Q: Is fireclay brick acidproof? Does clay brick anti corrosion when it's used to build chimney lining?

- Refractory bricks anti acid and alkali after high-temperature calcination, and anti-corrosion won't be a problem

- Q: Shale brick and clay brick? Answer before you know it

- Is the shale as raw material for high temperature baked bricks using shale and coal gangue, shale sintered porous brick, hollow shale brick, shale brick, high insulation, water wall and other types of modular brick.

- Q: What are the differences between fireclay brick and high alumina refractory brick?

- One is the high alumina, solid and hollow respectively, fused mullite as main raw material made of high-grade refractory materials, strong corrosion resistance, has the advantages of through mud treatment, good thermal shock stability. Good resistance to slag, used to build steel making furnace and glass furnace. High alumina brick is a kind of refractory material. Clay brick is also known as sintered brick, electric smelting corundum and low creep high alumina brick [1] with high grade bauxite, this kind of refractory brick's main component is AL2O3, which is suitable for large and small buildings with artificial bulk. High thermal stability. A neutral refractory material with more than 48% of alumina oxide content, clay brick has clay (including shale, molding, coal gangue and other powder) as the main raw materials, cement rotary furnace lining. The product has a small high-temperature creep, one is clay. From bauxite or other high content of aluminium oxide raw materials' forming and firing, refractoriness is above 1770 deg. High R.U.L and medium-sized hot-blast furnace is different firstly in the material, forming from drying and roasting

- Q: What is the sintering of non clay bricks?

- Unfired bricks are bricks used to build walls relative to sintered bricks.

- Q: How about clay bricks?

- The strength of brick can be judged by the sound produced by two bricks colliding with each other.Two hands each take a brick, gently hit, such as a uniform, crisp sound, indicating brick high strength, good quality, if the collision sound hoarse or stuffy, it shows that brick strength is low.2. to observe the crack state of bricks, elliptical repeat crack if large surface of the brick on the head, like twistcore, called "spiral brick"; some bricks will be broken, the shell off angle, crack and other symptoms, hand picked up the pieces of a pinch, immediately in powder form. The inner core is yellow and honeycombed. It is called "crisp brick", which belongs to the waste brick.3. to observe the color of brick brick brick section: open, heart was uniform black, no unburned carbon brick, high strength of such. On the contrary, the intensity is low.

- Q: What kinds of annealing furnace refractory bricks there are?

- But the energy saving effect is good, but also can use lightwight heat insulating brick, but the price is higher than that of clay brick

Send your message to us

Fireclay Brick - China Made Good Thermal Shock Resistance for Furnaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords