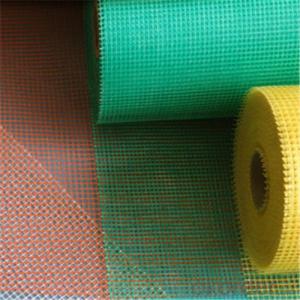

Fiberglass Lampshade Fabric YX-GF(SL) 105 Glass Fiber Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Model Number: | |||

| Application: | Surface Treatment: | Width: | |||

| Weave Type: | Yarn Type: | Alkali Content: | |||

| Standing Temperature: | colour: | high temperature resistance: | |||

| breadth: | thickness: |

Packaging & Delivery

| Packaging Detail: | carton or plastic woven bags |

| Delivery Detail: | 10 work days |

Specifications

silica gel coated glass fiber cloth

thicknes:0.8mm-3.0mm

breadth:1000mm

high temperature resistance:350~450C

- Q: Is fiberglass fabric resistant to termites?

- Termites do not spare fiberglass fabric when it comes to their voracious appetite for organic materials like wood, paper, and fabric. Although fiberglass fabric may not be the ideal feast for termites, they can still wreak havoc on it by chewing through or using it as a gateway to other materials. Hence, safeguarding fiberglass fabric from termite infestation is crucial. Employing termite barriers, conducting routine inspections, and treating the vicinity for termites, if needed, are all necessary precautions to undertake.

- Q: How does fiberglass fabric compare to Kevlar fabric?

- Fiberglass fabric and Kevlar fabric are both widely used in various industries for their desirable properties, but they have distinct differences that make them suitable for different applications. Firstly, fiberglass fabric is composed of fine strands of glass fibers that are woven together. It is known for its excellent strength and durability, making it a popular choice for applications requiring high tensile strength and resistance to abrasion. Fiberglass fabric is also highly resistant to heat and chemicals, making it suitable for use in insulation, electrical components, and corrosion-resistant applications. On the other hand, Kevlar fabric is made from synthetic para-aramid fibers, which are known for their exceptional strength-to-weight ratio. Kevlar fabric is significantly stronger than fiberglass fabric, as it possesses a higher tensile strength. This makes it ideal for applications where weight reduction and high impact resistance are critical factors, such as bulletproof vests, body armor, and aerospace components. Another notable difference between the two fabrics is their resistance to heat. While fiberglass fabric has excellent heat resistance, Kevlar fabric exhibits remarkable flame resistance, making it highly suitable for applications where fire protection is crucial, such as firefighting suits and thermal insulation. In terms of cost, fiberglass fabric is generally more affordable compared to Kevlar fabric, which is relatively expensive due to its advanced manufacturing process and superior performance characteristics. In conclusion, the choice between fiberglass fabric and Kevlar fabric ultimately depends on the specific requirements of the application. Fiberglass fabric excels in providing strength, durability, and resistance to heat and chemicals, while Kevlar fabric offers exceptional strength-to-weight ratio, impact resistance, and flame resistance.

- Q: Can fiberglass fabric be used for insulation in aerospace structures?

- Indeed, fiberglass fabric proves to be a viable option for insulating aerospace structures. Possessing a lightweight and pliable nature, this material exhibits exceptional thermal insulation characteristics. By effectively capturing and minimizing heat transfer, it becomes an appropriate choice for safeguarding aerospace structures that necessitate precise temperature control. Moreover, fiberglass fabric's resistance to fire, chemicals, and moisture enhances its suitability for implementation in aerospace contexts. The material's optimal combination of strength-to-weight ratio and durability renders it an ideal selection for insulating diverse components within aerospace structures, including fuel tanks, engine compartments, and heating systems.

- Q: What are the different fiberglass fabric weaves for impact resistance?

- There are several different fiberglass fabric weaves that are known for their impact resistance. Some of the common weaves include plain weave, twill weave, satin weave, and leno weave. Each weave has its own unique characteristics and advantages when it comes to providing impact resistance in fiberglass fabrics.

- Q: Can fiberglass fabric be used for reinforcement in water purification tanks?

- Indeed, fiberglass fabric proves to be a valuable asset when it comes to reinforcing water purification tanks. Renowned for its remarkable strength-to-weight ratio and long-lasting nature, fiberglass fabric stands as an ideal choice for fortifying tanks that endure perpetual water exposure. By bolstering the tank's structure, it effectively safeguards against deformation or collapse caused by the water's weight or external pressures. Moreover, fiberglass fabric's resistance to corrosion and chemicals guarantees its integrity, preventing any potential water contamination throughout the purification procedure.

- Q: Can fiberglass fabrics be used for insulation in pipelines?

- Yes, fiberglass fabrics can be used for insulation in pipelines. They are commonly used due to their excellent thermal insulation properties, high temperature resistance, and durability.

- Q: Can fiberglass fabric be used for insulation in renewable energy projects?

- Insulation in renewable energy projects can utilize fiberglass fabric. This fabric is commonly used for thermal insulation in a variety of applications, including renewable energy projects. Its excellent insulating properties and high thermal resistance make it suitable for insulating components like pipes, ducts, and equipment in solar, wind, geothermal, and other renewable energy systems. Fiberglass fabric is famous for its ability to prevent heat transfer effectively due to its low thermal conductivity. This is crucial in renewable energy projects where minimizing heat loss or gain is vital for optimal system performance and energy efficiency. By employing fiberglass fabric insulation, the energy generated from renewable sources can be efficiently utilized without being wasted due to inefficient insulation. Moreover, fiberglass fabric is lightweight, flexible, and easy to handle, making it appropriate for various installation requirements. It can be easily cut, shaped, and wrapped around different components, ensuring a proper fit and efficient insulation coverage. In addition to its exceptional thermal properties, fiberglass fabric insulation also offers other advantages. It is non-combustible, meaning it does not burn or contribute to the spread of fire. This is particularly important in renewable energy projects where safety is of utmost importance. Additionally, fiberglass fabric is resistant to moisture, chemicals, and UV radiation, guaranteeing long-lasting insulation performance even in harsh environmental conditions. All in all, fiberglass fabric is a versatile and dependable choice for insulation in renewable energy projects. Its thermal resistance, ease of installation, and durability make it an ideal solution to maximize energy efficiency and ensure the smooth operation of renewable energy systems.

- Q: Can fiberglass fabric be used for mold making?

- Mold making can be accomplished using fiberglass fabric. This versatile material is commonly utilized in various industries, including mold making, due to its strength, durability, and resistance to heat and chemicals. To create a sturdy mold using fiberglass fabric, it is typically laminated with a resin, such as polyester or epoxy. The fabric is saturated with the resin and then applied to the desired shape or object. Once the resin cures and hardens, it forms a solid mold that can be used to produce replicas or castings. Fiberglass fabric molds offer several advantages. They are lightweight, making them easy to handle and transport. They also exhibit excellent dimensional stability, meaning they maintain their shape well over time. Furthermore, fiberglass molds are compatible with a wide range of materials, including concrete, plaster, and various resins. It is important to emphasize the importance of safety precautions when working with fiberglass fabric and resin. This includes wearing protective clothing, gloves, and a respirator to prevent inhalation of harmful fumes. Additionally, ensuring adequate ventilation in the workspace is crucial. In conclusion, fiberglass fabric is an effective choice for mold making due to its strength, durability, and resistance to heat and chemicals. When used correctly, fiberglass fabric molds can produce high-quality replicas and castings for diverse applications.

- Q: How is fiberglass fabric used in the medical industry?

- Fiberglass fabric is used in the medical industry for various applications. It is commonly used in the manufacturing of casts and splints, providing rigid support and immobilization to injured bones or joints. The fabric is lightweight, breathable, and offers excellent strength, making it an ideal choice for this purpose. Additionally, fiberglass fabric is used in the production of medical tapes and dressings, providing a durable and reliable material that can adhere securely to the skin.

- Q: How does fiberglass fabric perform in cryogenic temperatures?

- Due to its inherent properties, fiberglass fabric is able to perform exceptionally well in cryogenic temperatures. Cryogenic temperatures, which are defined as extremely low temperatures below -150°C (-238°F), are commonly encountered in applications such as aerospace, medical, and scientific research. One of the main reasons for the effectiveness of fiberglass fabric in cryogenic temperatures is its remarkable thermal insulation properties. This allows the fabric to effectively endure and safeguard against extreme fluctuations in temperature. Consequently, the structural integrity and performance of the fiberglass fabric remain intact even when subjected to cryogenic conditions. Moreover, fiberglass fabric exhibits a low level of thermal conductivity, meaning that it does not readily transfer heat. This characteristic is of utmost importance in cryogenic applications as it helps to minimize the transfer of heat between the extremely cold environment and the surrounding components. In addition to its exceptional thermal properties, fiberglass fabric also possesses high tensile strength, durability, and resistance to chemical corrosion. These qualities make it well-suited for use in cryogenic environments, where materials must endure extreme conditions and maintain their mechanical properties over an extended period of time. To summarize, fiberglass fabric offers dependable performance and protection in cryogenic temperatures, thus making it a favored choice in various industries that require materials capable of withstanding such harsh conditions.

Send your message to us

Fiberglass Lampshade Fabric YX-GF(SL) 105 Glass Fiber Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords