Fiberglass Mesh Cloth - Glass Fiber Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Alkali-Resistant Fiber Glass Mesh

Fiberglass Mesh is woven by fiberglass yarns, then alkaline-resistant latex coated. It owns great alkaline-resistant and high strength. As a perfect engineering material in construction, It is widely used to reinforce cement, stone, wall materials, roofing, gypsum and so on.

High Quality

Coating glue: Our coating glue is produced by Germany BASF which can keep more than 70% after days NaoH test.

The fiberglass yarn is manufactured by ourselves. We have 60 unites Platinum Crucibles to produce glass fiber, It owns 20% more strength and beautiful surface than normal fiberglass yarn.

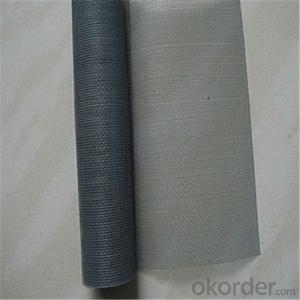

Material: Fiberglass Wire

Application: For Building internal and external wall insulation, waterproofing, Anti -crack, etc.

Specification:

1. Mesh Size: 3 MM X 3 MM, 4 MM X 4 MM, 5 MM X 5 MM, 8 MM X 8 MM,

10 MM X 10 MM

2. Unit Weight: For Outside Wall: 70g-160g/ Square Meter

For Inside Wall: 50g-60g/ Square Meter

Also can be your customized Max: 300G/M2

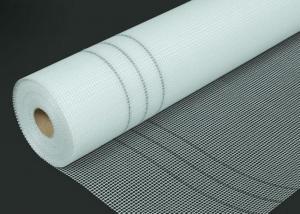

3. Width: 1 M-2 M. Mostly 1M Width

4. Length: 50 M/Roll

5. Packing: In Carton or Wrapped with Woven Bag, as your demand.

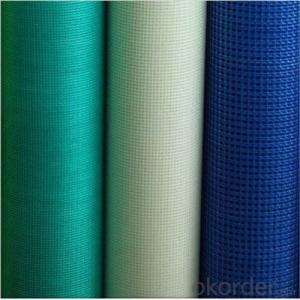

6. Colors: White (standard) or other blue green color.

Package:

Each Fiberglass Mesh Roll is put into PVC bag or Shrink Bag, and then put into Carton or Pallet.

- Q: How is fiberglass mesh used?

- The wall should be cleaned before paving and the pits will be patched and leveled

- Q: Where are the steel wire mesh and the alkali resistant grid cloth used in the exterior wall insulation?

- Two different wall plastering joints, to play a role in cracking; generally in the amount of graphics can be directly in the report to see the amount of engineering;Wire mesh and mesh cloth each have their own uses! Specific to see your design drawings.

- Q: What kind of wall fabric is covered with fiberglass mesh? Do you apply the powder or the powder? Thank you

- The interior powder is usually used at the joint of the wall (there is a mesh fabric specially used for joint, called adhesive tape or joint tape)

- Q: The building is how to choose the external wall thermal insulation material of glass fiber mesh cloth?

- The building often causes the perineum to warm up and contract cold and cause cracks. Reduce the service life, glass fiber mesh cloth can be the maximum restraint to reduce such adverse effects. The glass fiber mesh cloth is insulated and used in the outer part of the main structure so as to save indoor space. It is effective enough for indoor use

- Q: Do external insulation with alkali resistant fiberglass mesh cloth, why should the first layer be double or thickened?

- Therefore, the first floor insulation system adopts double-layer grid cloth and thickening protection layer, so as to enhance the impact resistance capability of the external insulation system.

- Q: Method for sampling alkali proof glass fiber mesh cloth

- Put the lid clockwise open, use a blender or other tools to avoid re mixing binder, binder separation phenomenon, stirring moderate, to avoid quality problems.

- Q: Can fiberglass mesh waste be recycled? What can you do if you can?

- What is more the incineration of waste mesh, which is of serious pollution damage behavior of soil air, acrylic mesh after high temperature can produce pungent odor, destroying the respiratory system and strong material, the core material is flame retardant fiberglass mesh product is burning up, so it is a serious pollution of soil caused by.

- Q: What's the price of fiberglass mesh?

- The elastic coefficient is high, the elongation within the elastic limit is related to the tensile strength of the alkali resistant fiberglass mesh cloth

- Q: What is the difference between alkali resistant fiberglass mesh cloth and high alkali glass fiber mesh cloth?

- The difference lies in the degree of use of alkali resistant glass fiber, at present there are very few domestic high alkali glass fiber products, the difference is in the base. Because the glass itself is not alkali resistant, so in the processing of glass fiber products add alkali resistant components, adding two zirconia, the glass fiber has certain effect on tolerance -OH.The mesh fabric produced with alkali resistant glass fiber is alkali resistant grid cloth, and the others are the same

- Q: Slotted walls, seams, seams, tape, or anti mesh cloth?

- Don't spend so much money to buy what tape and mesh cloth, is decorated well, to buy the cheapest dacron, remember to not want that kind of chemical fiber, cotton, cotton for a long time to decay.

Send your message to us

Fiberglass Mesh Cloth - Glass Fiber Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords