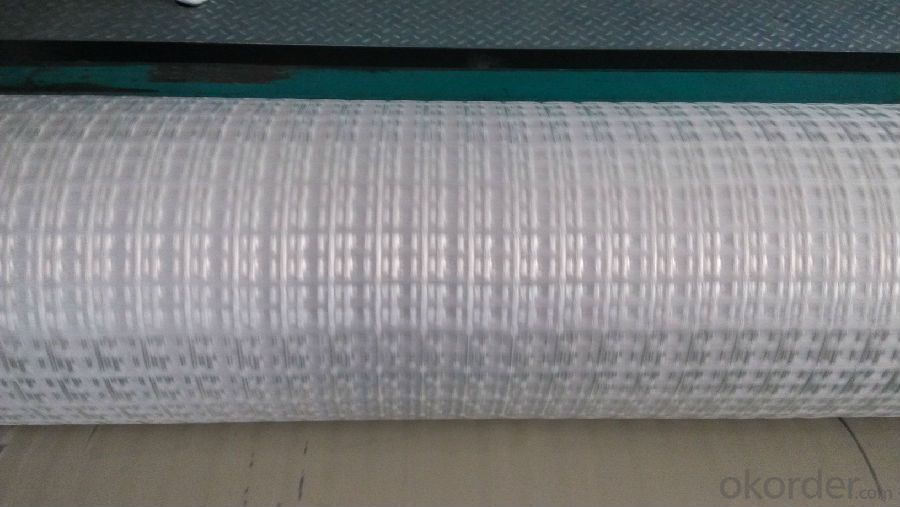

Teflon Coated Fiberglass Fabric Roof - High Quality Fiberglass Geogrid for Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Product has high strength, low elongation, high temperature, high modulus , light weight , good toughness, corrosion resistance , long life , etc. , can be widely used in the old concrete pavement , maintenance of airport runways , dams , river banks , while slope protection , road bridge , enhancement engineering field, to the road surface can be enhanced , reinforced to prevent pavement rutting fatigue crack , hot and cold telescopic cracks and reflection cracks below , and can the pavement load stress dispersion , extending pavement life .

2.Characteristics

The high tensile strength low - elongation : Fiberglass geogrid is a glass fiber , while the high tensile strength of glass fiber , more than other fibers and ordinary metals . Its high modulus , high resistance to deformation , elongation at break of less than 3% .

3.Application

Physical and chemical stability after special treatment agent coated handle , fiberglass geogrid to resist a variety of physical wear and chemical attack , but also to resist biological erosion and climate change to ensure that its performance is unaffected by the loss .

5.FAQ

Good thermal stability : the melting point of glass fibers is above 1000 °C , to ensure the stability of the glass fiber geogrids to withstand high temperature in a paving job .

- Q: How is fiberglass fabric used in the production of insulation jackets?

- Fiberglass fabric is used in the production of insulation jackets as it provides excellent thermal insulation properties. The fabric is woven from fine strands of glass, which create a tight and durable structure that helps trap and retain heat. It is commonly used as an outer layer in insulation jackets to prevent heat loss, as well as to provide protection from external elements such as moisture and abrasion. Additionally, fiberglass fabric is lightweight, flexible, and resistant to fire, making it an ideal choice for insulation jackets used in various industries.

- Q: Can fiberglass fabrics be used for reinforcement in furniture or fixtures?

- Yes, fiberglass fabrics can be used for reinforcement in furniture or fixtures. Fiberglass fabrics are known for their strength, durability, and flexibility, making them ideal for reinforcing various types of furniture and fixtures. They can be used to reinforce the frames of chairs, sofas, and other seating furniture to provide additional support and stability. Fiberglass fabrics can also be used to reinforce the surfaces of tables, countertops, and shelves, enhancing their ability to withstand heavy loads and resist cracking or warping. Furthermore, fiberglass fabrics can be molded into different shapes and sizes, allowing them to be used for reinforcing various types of furniture or fixtures.

- Q: Can fiberglass fabric be used for insulation in telecommunications infrastructure?

- Fiberglass fabric is indeed a suitable option for insulation in telecommunications infrastructure. Its remarkable thermal insulation properties make it an optimal choice for insulating various components within the telecommunications industry. By effectively preventing heat loss or gain, it ensures that equipment functions within the desired temperature range. Moreover, fiberglass fabric's lightweight nature, flexibility, and easy installation process make it a convenient solution for insulating cables, antennas, and other infrastructure components. Additionally, its resistance to moisture, chemicals, and fire offers an extra layer of protection to the insulation system. All in all, fiberglass fabric is extensively utilized and considered an appropriate material for insulation in telecommunications infrastructure.

- Q: Can fiberglass fabric be used for making insulation boards?

- Indeed, insulation boards can be crafted using fiberglass fabric. This fabric is widely utilized in the production of insulation boards owing to its exceptional heat properties and fire resistance. Comprised of delicate glass strands, the fabric is skillfully interwoven to yield a resilient and adaptable material. By layering or compressing this fabric, the desired thickness and R-value, which gauges the insulation's ability to impede heat transfer, can be achieved. Moreover, fiberglass fabric exhibits resistance to moisture and actively discourages the growth of mold or mildew. In summary, the durability, thermal efficiency, and safety attributes of fiberglass fabric render it a favored option for insulation boards.

- Q: Are fiberglass fabrics resistant to shrinkage or stretching?

- Fiberglass fabrics are known for their resistance to both shrinkage and stretching.

- Q: How does fiberglass fabric perform in terms of dimensional stability?

- With its exceptional dimensional stability, fiberglass fabric proves to be highly reliable and well-suited for a wide array of uses. Thanks to the unique composition of its woven glass fibers, it possesses an impressive ability to resist changes in shape or size, even when subjected to extreme temperature fluctuations or mechanical stress. This stability ensures that fiberglass fabric maintains its original dimensions and shape over time, enabling it to consistently meet the required specifications and performance criteria. Moreover, the fabric's dimensional stability renders it ideal for applications in industries such as aerospace, automotive, and construction, where precise measurements and accuracy are essential. Overall, the outstanding dimensional stability of fiberglass fabric stands out as one of its key attributes, contributing to its extensive use and popularity across various sectors.

- Q: How is fiberglass fabric different from other types of fabric?

- The composition and unique properties of fiberglass fabric set it apart from other types of fabric. Unlike natural fabrics like cotton or silk, fiberglass fabric is woven from thin strands of glass. This distinctive composition gives fiberglass fabric several advantages over other fabrics. First and foremost, fiberglass fabric is renowned for its exceptional strength and durability. The glass fibers used in its production are incredibly strong and resistant to tearing, stretching, and general wear and tear. This makes fiberglass fabric ideal for applications that require durability, such as in construction or industrial settings. Additionally, fiberglass fabric exhibits high heat resistance. The glass fibers used in its production have a high melting point, allowing the fabric to withstand extreme temperatures without deteriorating or catching fire. This makes fiberglass fabric suitable for use in applications where heat resistance is crucial, such as in fire-resistant clothing or insulation materials. Furthermore, fiberglass fabric boasts excellent chemical resistance. It is not easily affected by most chemicals, including acids, alkalis, and solvents. This makes fiberglass fabric a preferred choice in industries where exposure to corrosive substances is common, such as chemical processing or automotive manufacturing. Moreover, fiberglass fabric is known for its lightweight nature. Despite its strength and durability, fiberglass fabric is relatively light, making it easier to handle and transport compared to other heavy-duty fabrics. This lightweight property is particularly advantageous in applications where weight is a concern, such as in the aerospace or automotive industries. Lastly, fiberglass fabric possesses excellent insulation properties. It is a poor conductor of heat and electricity, making it an effective insulator. This insulation capability is beneficial in various applications, including thermal insulation for buildings, electrical insulation for wiring, or even the production of protective clothing for workers in extreme environments. In conclusion, fiberglass fabric's exceptional strength, heat resistance, chemical resistance, lightweight nature, and insulation properties make it stand out from other fabrics. Its unique composition and advantageous properties make it a versatile and preferred choice in various industries and applications.

- Q: Can fiberglass fabric be used for insulation in nuclear power plants?

- Yes, fiberglass fabric can be used for insulation in nuclear power plants. Its excellent thermal insulation properties, fire resistance, and low thermal conductivity make it a suitable choice for insulating various components and systems in nuclear power plants.

- Q: Can fiberglass fabric be used for making flexible hoses?

- Certainly! Flexible hoses can be made using fiberglass fabric. This material is renowned for its exceptional strength and flexibility, rendering it suitable for a wide range of purposes. Notably, it is commonly employed in the production of flexible hoses due to its unique attributes. By weaving the fabric into a flexible structure, it becomes capable of enduring bending, twisting, and stretching without compromising its integrity. Furthermore, fiberglass fabric exhibits resistance against high temperatures, chemicals, and abrasion. This outstanding feature makes it highly suitable for hoses that transport fluids, gases, and even solids. Given its durability and flexibility, it comes as no surprise that fiberglass fabric is extensively utilized in demanding industries such as automotive, aerospace, and construction, where hoses are constantly exposed to rigorous conditions.

- Q: Is fiberglass fabric suitable for making outdoor furniture covers?

- Indeed, fiberglass fabric proves to be an ideal material for crafting covers for outdoor furniture. Renowned for its robustness and ability to withstand harsh weather, it becomes an exceptional choice for shielding outdoor furniture against rain, sunlight, and wind. Its resistance to water and UV rays, coupled with its capacity to endure extreme temperatures without deterioration or fading, further enhance its suitability. Furthermore, fiberglass fabric's lightweight nature simplifies handling and installation on furniture. It also fends off mold, mildew, and pests, ensuring the cleanliness and protection of your furniture. All in all, fiberglass fabric emerges as a dependable and enduring option for fashioning outdoor furniture covers.

Send your message to us

Teflon Coated Fiberglass Fabric Roof - High Quality Fiberglass Geogrid for Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords