FRP Pultrusion Profiles - Fiber Glass Reinforce Plastic/GRP Door-Solid

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

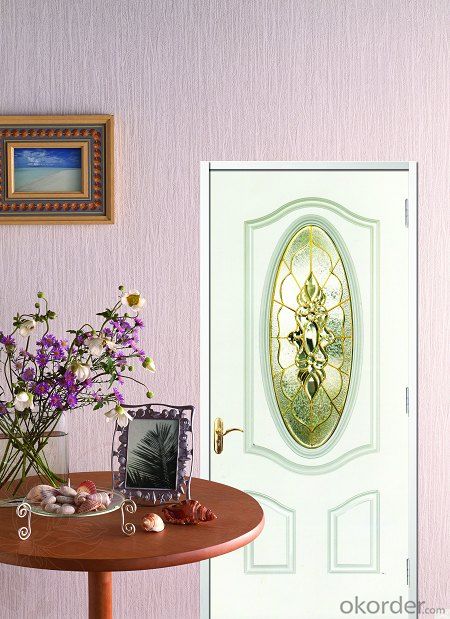

1. Great apperance

2. High intensity

3. Long service life

4.Good sound insulation and heat preservation

5. Customize colors

Product Description

The Advantages of FRP Door &Window

Fiber-reinforced plastic (FRP) (also fiber-reinforced polymer) is compositematerialmading of polymermatrix reinforced with fiber. It’s commonly used inthe aerospace, automotive, marine etc. FRP has distinct advantages that makethem attractive for a wide uses. One of its uses is making FRP doors andwindows. The advantages are:

(1) Excellent water-sealing.Withrain-proof plate, grooves and poles water drainage, doors and windows canisolate rain to outside completely.

(2) Effectual heat preservation. The FRP doors and windows’ heat resistance is almost twice as much as plastic-steeldoors and windows. In winter, it’ll be good temperature keeper, increasing roomtemperature about 5°.

(3) High intensity. It could sustainits own weight, do not bend, fade, distort or rust.

(4)Perfect sound insulation.Withelaborate structure design and rigorous connection, the sound insulation of FRPdoors and windows is below 20db, which is in accordance with DIDN4109.

(5)Easy-maintained.FRP doors andwindows have good resistance to acids, alkalis and waste gas salty substances.They hardly need maintenance, any cleaner made them clean and new as before.

(6)High durability. FRP doors andwindows have long service life, about 50 years, almost same age with the building.

(7) We can customize any color or wooden grain according to your need.We will provide high-quality service, fast delivery and reasonable price,satisfying all your need.

comparing with other

FRP window and door Contrast to Other Materialswindow

Item | Aluminum alloy window /door | PVC window /door | FRP window /door | |

Weight | About 15kg/sq.m | About 8 kg/sq.m | About 6.2kgsq.m | |

Intensity | Tensile strength about 157MPa | Tensile strength about 49.2MPa | Tensile strength about 250MPa | |

Corrosion resistance | Intolerance Hydrogen Fluoride(HF) | Intolerance Hydrogen Fluoride(HF) | Excellent corrosion resistance | |

Insulativity | Good conductor, uninsulate | Have steel liner, bad insulativity | Good insulation and security | |

Durability | Service life less than 20 years. Frangibility | Service life less than 20 years. Frangibility | Service life more than 30 years. Durability | |

Cost | Cheap but high maintenance costs | Expensive and high maintenance costs | Reasonable price | |

Commonality | Over -20°C | -20°C-40°C, in high temperature easy to transfigure. | -40°C-80°C | |

Social benefits | High energy consumption, not environmentally-friendly window | Green product. | Green product |

- Q: Can FRP pultrusion profiles be used in the renewable energy and solar power industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the renewable energy and solar power industry. These profiles offer several advantages such as high strength, durability, corrosion resistance, and lightweight properties, making them suitable for various applications in the industry. FRP pultrusion profiles can be used for structural components, support structures, mounting systems, and other applications in solar panels, wind turbines, wave energy devices, and other renewable energy systems.

- Q: Are FRP pultrusion profiles resistant to biological growth, such as mold or mildew?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to biological growth, including mold and mildew. FRP materials are inherently non-porous, making it difficult for microorganisms to attach and grow on their surface. Additionally, FRP pultrusion profiles are typically manufactured using a combination of resin and glass fibers, which are both naturally resistant to biological growth. Unlike traditional materials such as wood or metal, FRP does not provide an ideal environment for mold or mildew to thrive. The smooth and non-porous surface of FRP profiles prevents moisture absorption, which is essential for the growth of microorganisms. Furthermore, FRP materials do not contain organic compounds that can support the growth of mold or mildew, making them highly resistant to biological degradation. In applications where resistance to biological growth is crucial, FRP pultrusion profiles offer a significant advantage over alternative materials. They are commonly used in environments with high humidity, moisture, or exposure to water, such as marine, agricultural, or wastewater treatment facilities. Additionally, FRP profiles are frequently employed in indoor applications where mold or mildew growth can be a concern, such as in sanitary areas or food processing plants. Overall, FRP pultrusion profiles provide excellent resistance to biological growth, including mold and mildew. Their non-porous nature, combined with the inherent resistance of the materials used in their manufacturing, make them a durable and long-lasting solution in environments where microbial growth is a potential issue.

- Q: Are FRP pultrusion profiles resistant to electrical arcing?

- FRP pultrusion profiles are generally resistant to electrical arcing. This is because they are made from non-conductive materials like fiberglass reinforced plastic. These profiles do not conduct electricity, which makes them ideal for applications where electrical arcing or conductivity is a concern. However, it is important to note that the specific resistance to electrical arcing may vary depending on the specific composition and design of the FRP pultrusion profiles. It is recommended to consult with the manufacturer or supplier of the profiles to ensure they meet the required electrical resistance standards for a particular application.

- Q: What is the compression strength of FRP pultrusion profiles?

- The compression strength of FRP (Fiber Reinforced Polymer) pultrusion profiles varies depending on several factors such as the type of resin, fiber orientation, and design. However, on average, FRP pultrusion profiles have a compression strength ranging from 10,000 to 50,000 pounds per square inch (psi). It is important to note that these values are approximate and may vary depending on the specific application and intended use of the FRP profiles. Additionally, manufacturers typically provide technical data sheets that outline the compression strength and other mechanical properties of their FRP pultrusion products, which can be utilized for more accurate and reliable information.

- Q: Can FRP pultrusion profiles be used in the construction of wastewater treatment tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the construction of wastewater treatment tanks. FRP pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them an ideal choice for applications in harsh environments such as wastewater treatment facilities. FRP pultrusion profiles are made by pulling continuous fibers, typically glass or carbon, through a resin bath and then through a heated die to form the desired shape. This process results in profiles with consistent cross-sections and excellent mechanical properties. In the construction of wastewater treatment tanks, FRP pultrusion profiles can be used for a variety of purposes. They can be employed as structural elements, such as beams, columns, and bracing systems, providing the necessary strength and stiffness to support the tank structure. FRP profiles can also be used as reinforcement in concrete structures, enhancing their durability and resistance to chemical attack from the wastewater. Furthermore, FRP pultrusion profiles can be designed to resist the corrosive effects of the chemicals and gases present in wastewater treatment tanks. Unlike traditional materials like steel or concrete, FRP is highly resistant to corrosion, ensuring a longer service life and reduced maintenance costs. Additionally, FRP profiles offer advantages in terms of installation and transportation. They are lightweight, allowing for easier handling and reduced labor requirements during construction. The modular nature of FRP profiles also facilitates quick assembly and disassembly, making maintenance and modifications more convenient. Overall, the use of FRP pultrusion profiles in the construction of wastewater treatment tanks provides numerous benefits, including high strength, corrosion resistance, durability, and ease of installation. These advantages make FRP a reliable and cost-effective choice for wastewater treatment facilities.

- Q: Are FRP pultrusion profiles resistant to caustic soda?

- FRP pultrusion profiles are generally immune to caustic soda, which is a potent alkaline substance capable of corroding certain materials. However, FRP pultrusion profiles consist of robust fibers (like fiberglass) combined with a resin matrix (such as polyester or epoxy). This composite construction renders them highly resistant to chemicals, including caustic soda. Consequently, FRP pultrusion profiles find extensive application in industries prone to exposure to corrosive substances, such as chemical processing, wastewater treatment, and mining. It is worth noting that the choice of resin in the FRP profiles, along with the concentration and temperature of the caustic soda, can impact the overall level of resistance.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- FRP pultrusion profiles are generally resistant to fungal growth. The composite materials, like resins and fibers, used in pultrusion possess inherent resistance to biological degradation, including attacks from fungi. The non-porous nature of FRP pultrusion profiles also poses difficulties for fungi to penetrate and grow on the surface. Furthermore, the manufacturing process involves curing the composite materials at high temperatures, which adds to their resistance against fungal growth. However, it is important to acknowledge that no material is entirely impervious to fungal growth in all conditions. Factors such as high humidity, prolonged exposure to moisture, and inadequate maintenance practices can still contribute to fungal growth on FRP pultrusion profiles, albeit to a lesser extent compared to materials like wood or metal. Regular inspection and appropriate cleaning are crucial to sustain the fungal resistance of FRP pultrusion profiles throughout their lifespan.

- Q: Can FRP pultrusion profiles be used in renewable energy projects?

- Yes, FRP pultrusion profiles can be used in renewable energy projects. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength, durability, and corrosion resistance, making them suitable for various applications in renewable energy projects. They can be used in the construction of wind turbine blades, solar panel frames, and structural supports for renewable energy infrastructure. Additionally, FRP pultrusion profiles can provide cost-effective solutions by reducing maintenance requirements and improving the overall performance of renewable energy systems.

- Q: Are FRP pultrusion profiles UV resistant?

- FRP pultrusion profiles are known for their UV resistance. This is because manufacturers use a combination of polymer resin and reinforced fibers, like fiberglass, to create these profiles. These materials naturally possess UV resistant properties, which means that FRP pultrusion profiles can withstand prolonged exposure to sunlight and ultraviolet radiation without getting damaged. For outdoor applications, such as in construction, infrastructure, and marine industries, UV resistance is an important characteristic. However, it's worth noting that the level of UV resistance can vary depending on the specific resin and fiber composition used in the manufacturing process. To get precise information about the UV resistance of FRP pultrusion profiles for a specific application, it's advisable to consult the manufacturer or supplier.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical packaging?

- Yes, FRP pultrusion profiles are highly resistant to chemicals used in pharmaceutical packaging. The unique properties of fiberglass reinforced plastic, such as its corrosion resistance and non-reactivity to most chemicals, make FRP pultrusion profiles an ideal choice for pharmaceutical packaging applications.

Send your message to us

FRP Pultrusion Profiles - Fiber Glass Reinforce Plastic/GRP Door-Solid

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords