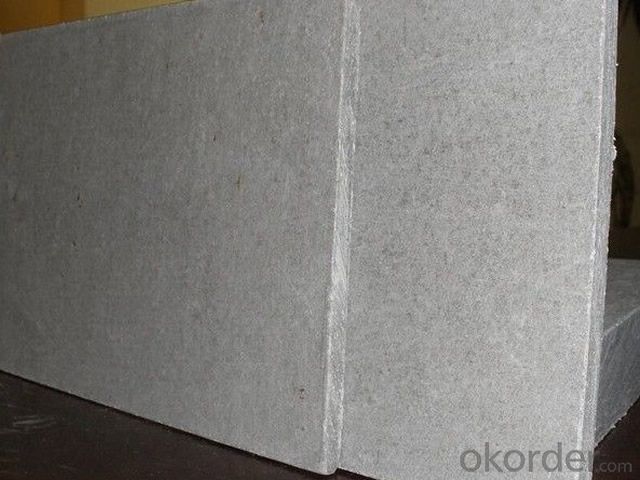

Fiber Cement Board 100% Non-Asbestos Smart Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

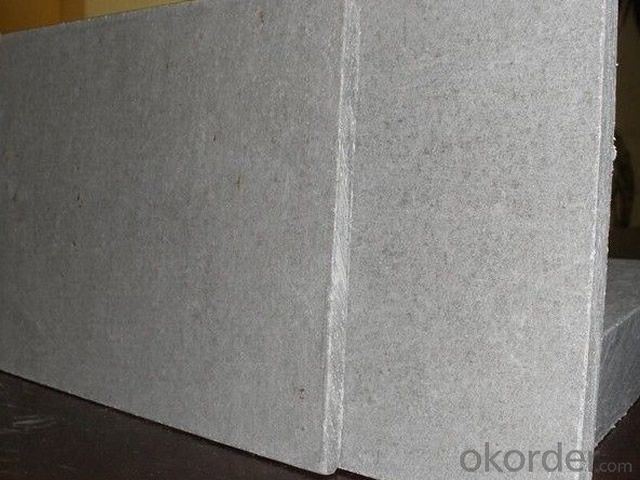

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

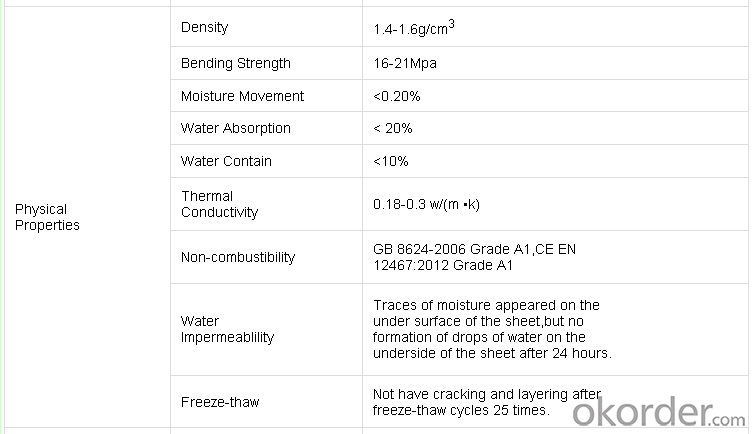

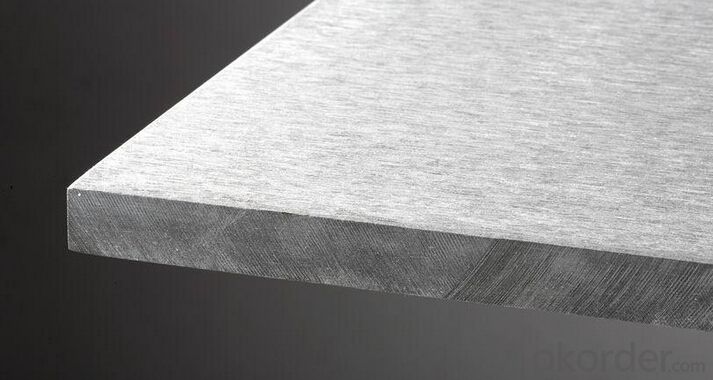

Main Product Features:

It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and environmental friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q: do i need to put cementious backer board behind a fiberglass surround shower unit?

- Consult the product manual or the manufacturers web site to be sure, but green board should be sufficient. Cement backer board is meant for tile.

- Q: What are the prospects for the development of wood fiber cement board?

- Applications: decorative interior and exterior walls, floors, ceilings, furniture, soundproof walls, Portland cement and Portland cement are called outside the continent. Plate used in the cement should be superior to the wood are some paper mills out of the crude fiber is environmentally friendly raw materials. There are other auxiliary inorganic additives to join and the addition of quick-setting agents to ensure the quality of the product. Later in the building should be continuously improve the scope of application of its products than the impact of the plaster board is much stronger. After the market will flourish. From the gray board of smallpox to the application of gypsum board with a decade of time to promote.

- Q: Why plastic materials use glass fiber reinforced

- Some physical properties of plastic are generally worse than metal, adding glass fiber can improve the modulus of plastic products, but also can enhance the heat resistance of plastic products, but after adding glass fiber, the plastic will become more brittle, toughness decreased.

- Q: We have drywall in our kitchen that was painted with a smooth semi-gloss paint a good 8 yrs ago. We'd like to install 3x6 tumbled marble as a backsplash over the drywall. It's about 1/4 thick so probably slightly heavier than say, the tiny square glass tiles that come on a 12x12 netting. One person at the Home Depot said we could just sand and scrape up the drywall and then apply the thinset and install the marble. Another said we might want to use a cement backing. We aren't really DIYers and would so we don't want to create extra work with the cement backing if it isn't needed. That said, we don't want the drywall to start peeling and the marble tiles to start falling off after a short amount of time. Please advise. Thank you!

- I would recommend screwing wonder board over the drywall before putting the tile up. This will give you a long lasting application. It will not up your cost a whole lot and you will be much happier in the long run.

- Q: Outdoor use of cement pressure plate can not

- Cement pressure plate, also known as fiber cement pressure plate or cement fiber pressure plate, is a natural fiber and cement as raw material, by the pulp, forming, cutting, pressing, curing a new type of building plate. Is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features. It is based on siliceous and calcareous materials as the main substrate, with cellulose fiber reinforced materials, mixed with other auxiliary materials, through the copy forming, high pressure curing the formation of a new type of building materials.

- Q: When laying down cement backer board for a slate tile installation, I laid the board a bit too far from the wall, so I pushed it until it was flush with the wall. I think by doing this I must have shifted some of the thinset underneath, because I noticed that the board has a slight dip in it, of maybe 1/16-1/8. Is this going to be a problem, or will it be taken care of when I put thinset over it to lay the tile. This is obviously my first time laying tile.On a side note, when laying slate, is it best to use thinset or medium set, I've heard conflicting opinions.

- If you use medium set, any differences in the scale you described can be corrected fairly nicely.

- Q: Toilet decoration with light steel keel gypsum board vertical wall. What can be done with a hanging brick?

- To hang brick, you can use light steel keel partition, but to use cement board cover, can not use gypsum board

- Q: I know cement board to cement board is taped with thinset and fibatape, but what about the seam at the sides that meet drywall? How should these be taped. What Materials should be used?

- I use a self adhesive fiberglass tape over that seam, and apply 90 minute joint compound over the tape. I assume you are bringing your tile to, or just over that edge anyway. I also assume that that particular joint will be outside the shower curtain or glass, whichever you will be using.

- Q: i can ollie on a rug ok but then on the cement my board moves and the back wheels dont get up i know i am doing the ollie right but when i try it on the cement the board moves and the back wheels dont go up i really need help because most of my friends skate and they are really good and i would like to start skating but i dont know if i am good please give me some tips about ollieing on the cement thanks!

- Your pushing your board back with your feet. Try not to do this and practice. The only way to be good in skateboarding is practicing everything hard.

- Q: Wood keel cement pressure plate partition wall tiles

- Before the tiles, the cement board should first use the interface agent to brush, then paint a layer of 1 cm or so of cement mortar, the label is appropriate high; 24 hours after the water to do maintenance (to prevent the paint layer too dry), 48 hours After the tile can be posted (at this time the strength of the paint layer has not yet reached, when the tile can not be applied to hit the force); tiles must be fully soaked.

Send your message to us

Fiber Cement Board 100% Non-Asbestos Smart Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords