Aluminum Extrusion Profiles F Channel 8080 for Equipment Framework Aluminum Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Extruded Aluminium 8080 for Equipment Framework Aluminum Profiles

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Extruded Aluminium 8080 for Equipment Framework Aluminum Profiles

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Extruded Aluminium 8080 for Equipment Framework Aluminum Profiles

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

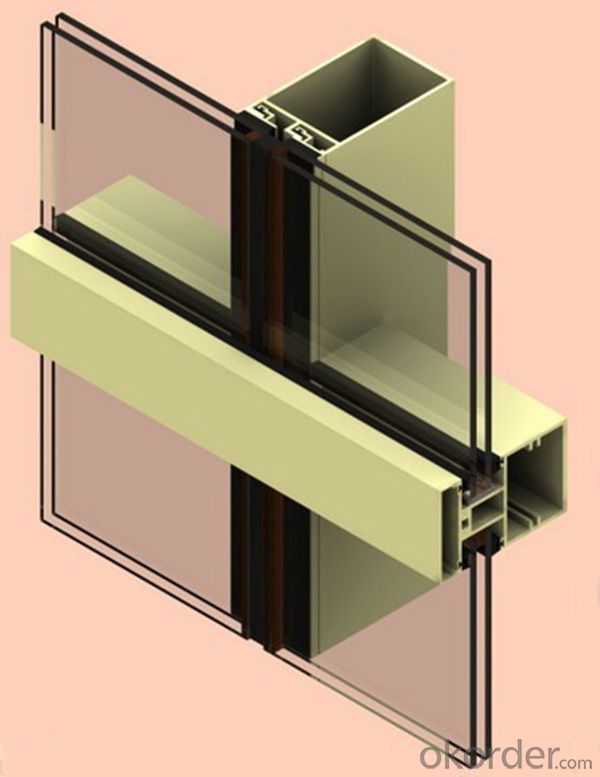

5. Image of Extruded Aluminium 8080 for Equipment Framework Aluminum Profiles

6. Package and shipping of Extruded Aluminium 8080 for Equipment Framework Aluminum Profiles

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Are there any specific maintenance requirements for aluminum profiles?

- Maintenance requirements for aluminum profiles are necessary to ensure their longevity and performance. To begin with, it is crucial to regularly clean the profiles to eliminate any dirt, dust, or contaminants that may have settled on the surface. This can be achieved by using a mild detergent or soap mixed with water and a soft cloth or sponge. It is important to avoid using harsh or abrasive cleaners as they can harm the protective coating on the aluminum. In addition, periodic inspections should be conducted to identify any signs of damage or wear on the aluminum profiles. This involves checking for dents, scratches, or corrosion. If any damage is detected, immediate attention should be given to prevent further deterioration. Moreover, lubrication may be necessary for specific moving parts or joints in the aluminum profiles. The manufacturer's recommendations should be followed, and a suitable lubricant or silicone spray can be used. Furthermore, it is crucial to inspect and maintain the protective coating on the aluminum profiles. Over time, this coating may wear off, which exposes the aluminum to potential corrosion. In such situations, applying a new coating or protective sealant is advisable to maintain the durability and appearance of the profiles. Lastly, it is essential to adhere to any specific maintenance guidelines provided by the manufacturer. These guidelines may include specific instructions or recommendations for cleaning, maintenance, and repair. Following these guidelines will ensure that the profiles remain in good condition and retain their functionality and aesthetic appeal for an extended period of time.

- Q: This question asks for methods to preserve the look and functionality of aluminum profiles to ensure they last longer and remain in good condition.

- <p>To maintain the appearance and performance of aluminum profiles over time, follow these steps: 1. Regularly clean the profiles with a soft cloth and mild soap to remove dust and dirt. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the profiles are exposed to harsh weather conditions or chemicals. 4. Inspect the profiles periodically for signs of wear, corrosion, or damage, and repair or replace them as needed. 5. Lubricate moving parts with appropriate oils or grease to ensure smooth operation. 6. Avoid overloading the profiles or using them beyond their specified weight capacity. By following these maintenance practices, you can prolong the life and performance of aluminum profiles.</p>

- Q: What are the differences between horizontal and vertical aluminum profiles?

- Horizontal vertical hanger in the middle on the head,Therefore, the horizontal number will affect the surface a little, and when you have to find non decorative surface hangingThe vertical head is better, a hanging point, just cut off

- Q: How do aluminum profiles perform in wind-resistant structures?

- The performance of aluminum profiles in wind-resistant structures is widely recognized. They possess inherent strength and durability, enabling them to endure high wind pressures while maintaining their structural integrity. The lightweight characteristic of aluminum makes it an ideal material for wind-resistant structures as it reduces the overall building load without compromising strength. Aluminum profiles exhibit high tensile strength and resistance to corrosion, making them suitable for harsh weather conditions, including strong winds. They also possess a high stiffness-to-weight ratio, which effectively distributes wind load and minimizes deflection. This characteristic is crucial in wind-resistant structures as it prevents excessive movement and ensures the safety of the building and its occupants. Moreover, aluminum profiles offer easy fabrication and customization, allowing for the creation of intricate and innovative designs. This design flexibility empowers architects and engineers to optimize the structure's aerodynamics, further enhancing its resistance to wind forces. Additionally, aluminum profiles can be combined with other materials, such as glass or composite panels, to establish a more robust and efficient wind-resistant system. In conclusion, aluminum profiles are incredibly reliable and efficient for wind-resistant structures. Their strength, lightweight nature, corrosion resistance, and design flexibility make them an exceptional choice for constructing buildings that can endure strong winds and guarantee the safety and durability of the structure.

- Q: How do aluminum profiles contribute to water management strategies?

- Aluminum profiles play a crucial role in water management strategies due to their inherent properties and versatility. These profiles are commonly used in the construction of various water management infrastructure such as pipes, channels, and tanks, among others. Firstly, aluminum profiles are lightweight yet sturdy, making them ideal for constructing water pipes. Their lightweight nature allows for easy transportation and installation, while their strength ensures durability and resistance to corrosion. This is particularly important in water management systems as it reduces the risk of leaks and damages, ensuring the efficient and effective transport of water resources. Secondly, aluminum profiles are highly resistant to corrosion. Corrosion is a major concern in water management as it can contaminate water, reduce its quality, and damage infrastructure. By utilizing aluminum profiles, the risk of corrosion is significantly reduced, leading to improved water quality and longevity of the infrastructure. Additionally, aluminum profiles are highly customizable and can be fabricated into various shapes and sizes, allowing for the creation of efficient water management systems. These profiles can be used to construct channels, culverts, and tanks, which are crucial components of water management infrastructure. The versatility of aluminum profiles enables engineers and designers to create efficient and effective systems that can handle large volumes of water, ensuring proper water management in various scenarios such as irrigation, flood control, and wastewater treatment. Moreover, aluminum is a sustainable material that can be recycled indefinitely without losing its properties. This makes aluminum profiles an environmentally friendly choice, aligning with sustainable water management practices. By using aluminum profiles, water management strategies can minimize their environmental impact and contribute to a more sustainable future. In summary, aluminum profiles have a significant impact on water management strategies. Their lightweight yet sturdy nature, corrosion resistance, versatility, and sustainability make them indispensable in the construction of water management infrastructure. By utilizing these profiles, water management systems can be built to efficiently and effectively handle water resources, reducing the risk of contamination, improving water quality, and promoting sustainability.

- Q: Can aluminum profiles be used in agricultural applications?

- Indeed, aluminum profiles find utility in agricultural applications. The strength, durability, and corrosion resistance of aluminum render it a perfect material for diverse agricultural structures and equipment. One can utilize it for constructing greenhouse frames, irrigation systems, grain storage bins, livestock housing, and beyond. Moreover, aluminum profiles possess a lightweight nature, simplifying their handling and installation procedures. Furthermore, their exceptional thermal conductivity facilitates efficient temperature regulation within agricultural settings. On the whole, aluminum profiles present a multitude of advantages and are progressively gaining popularity in the agricultural sector.

- Q: Are aluminum profiles suitable for medical equipment and devices?

- Yes, aluminum profiles are suitable for medical equipment and devices. Aluminum is a versatile material that offers several advantages for medical applications. Firstly, it is lightweight, making it ideal for portable medical devices. This allows for ease of transportation, especially in emergency situations. Additionally, aluminum is corrosion-resistant, which is crucial for maintaining the sterility and cleanliness of medical equipment. The material is also durable and can withstand harsh environments and regular cleaning and sterilization procedures. Furthermore, aluminum profiles can be easily customized and fabricated into various shapes and sizes, making them adaptable for different medical device designs. Overall, the properties of aluminum make it a reliable and suitable choice for medical equipment and devices.

- Q: Are aluminum profiles resistant to termites and insects?

- Yes, aluminum profiles are highly resistant to termites and insects. Unlike wood, which is susceptible to termite infestations and insect damage, aluminum is a nonporous material that does not provide a food source for these pests. Additionally, aluminum profiles are typically coated with protective finishes, such as powder coating or anodizing, which further enhance their resistance to termites and insects. This makes aluminum profiles a durable and long-lasting option for various applications, such as window frames, door frames, and other construction projects where termite or insect damage is a concern.

- Q: Are aluminum profiles suitable for use as exterior walls in high-rise buildings?

- <p>Yes, aluminum profiles can be used for exterior walls in high-rise buildings. They offer several advantages such as high strength, low weight, corrosion resistance, and ease of maintenance. Aluminum profiles are also known for their durability and sustainability, making them an excellent choice for modern architecture. They can be used in various applications, including curtain walls, window frames, and structural components, due to their versatility and adaptability to different design requirements.</p>

- Q: What materials are used for aluminum profile packing?

- Aluminum packaging standard is generally pearl cotton and kraft paper packaging, but depends on the degree of product requirements,

Send your message to us

Aluminum Extrusion Profiles F Channel 8080 for Equipment Framework Aluminum Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords