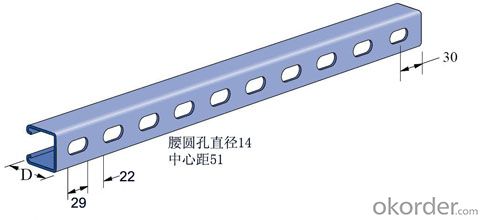

equilateral H type steel, galvanized Z type steel, solar stent type Z steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 8000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Design and construction of atlas and complete, all the stress components -- type steel and fastener (with locking serrations) can realize the assembly components of a rigid mating,connecting without displacement, no order adjustment, accurate positioning. Shock and vibration, enhance the shear resistance capacity of bracket nodes.

And tracking services, real-time guidance, doubts on the construction site

Technical personnel at the scene guidance, FAQ, do mechanics analysis in real-time tomeet in the construction of the special support and hanger, and the coordination of various professional bundle

And fast installation, short construction period

The installation speed is 6~8 times of traditional practices, in reducing the cost ofmanufacture and installation of 1/2. All professions and trades cross operation, improve work efficiency, shorten the construction period.

And long service life, convenient maintenance

The use of the environment, according to special requirements of customers, provide different process materials are electric galvanized (Leng Duxin), hot dip galvanized andgalvanized coating powder (spray)

Quasi - materials budget

Ensure the products for the standardization of semi-finished products, model identificationwith clear, standardized management, materials and the fittings on the waste and loss ofrare.

And excellent quality assurance

With ISO9000, ISO9002 standard, ensure the stability of the whole system integrity andhanger.

Good generality

And the combination of standard component types of rich, available options. Ensure all kinds of support under different conditions, simplicity, applicability and flexibility.

And environmental protection

Construction without welding and flame, will not impact on the environment and office.

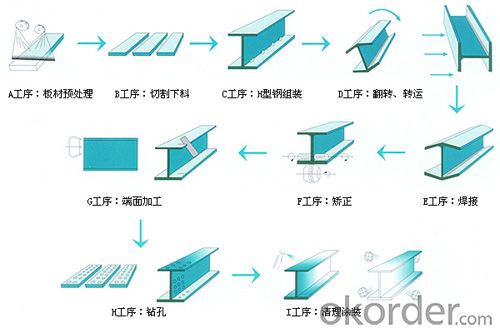

Our factory has ten fully automatic and semi automatic cold bending production line eight,has its own development team, the independent development of mold design to meet the various needs of customers. Product appearance, size precision, reasonable design,convenient use saves the massive manpower and physical for customers, reducing the cost, the products are widely used in the construction industry, automobile manufacturing,solar power generation, machinery manufacturing, power transmission tower, bridge, shipmilitary aviation industry, railway and highway construction, machine room

- Q: What are the considerations for designing steel structures for radiation protection?

- When designing steel structures for radiation protection, several considerations need to be taken into account. Firstly, the thickness and density of the steel should be chosen appropriately to provide the necessary shielding against radiation. The higher the energy of the radiation, the thicker the steel required. Additionally, the structural integrity of the steel must be ensured to withstand the weight and potential impact of any radiation shielding materials that may be added. The steel should be able to resist bending, buckling, and other forms of deformation under load. Furthermore, the design should consider factors such as accessibility for maintenance and installation of radiation shielding materials. Adequate space should be allocated for the placement and replacement of shielding components. Lastly, it is essential to consider the overall cost and feasibility of the design. The chosen steel structure should be cost-effective and practical for the intended application, while still meeting the necessary radiation protection requirements.

- Q: What are the advantages and disadvantages of using pre-engineered steel structures?

- Using pre-engineered steel structures has both advantages and disadvantages. One significant benefit is their exceptional durability, allowing them to withstand harsh weather conditions like hurricanes, earthquakes, and heavy snow loads. Additionally, steel structures resist rot, pests, and fire, making them a safer option for buildings. Another advantage is the cost-effectiveness of pre-engineered steel structures. Compared to traditional construction methods, they are typically less expensive since their components are manufactured off-site and then assembled on-site. This also significantly reduces construction time, saving both time and money. Moreover, pre-engineered steel structures offer great flexibility in terms of design and layout. The steel components can be easily customized to meet specific needs and can be modified or expanded in the future. This provides greater adaptability and versatility compared to other construction methods. However, there are also some disadvantages to consider. One drawback is the limited aesthetic options. Steel structures are often associated with an industrial or commercial look, which may not be suitable for all building types or desired architectural styles. Another disadvantage is the potential for corrosion. While steel structures are generally resistant to rust and corrosion, proper maintenance is crucial to prevent any potential issues. Regular inspections, cleaning, and applying protective coatings are necessary. Additionally, pre-engineered steel structures may not be suitable for all locations or environments. For instance, in areas with high seismic activity, additional engineering and reinforcement may be required to ensure the structure's stability. Similarly, extreme climates may necessitate additional insulation or heating and cooling systems to maintain comfortable indoor temperatures. In conclusion, pre-engineered steel structures offer advantages such as durability, cost-effectiveness, and design flexibility. However, they also have disadvantages including limited aesthetic options, potential corrosion issues, and the need for additional engineering considerations in certain locations or environments. Careful evaluation of these factors and consideration of specific project requirements are important before choosing pre-engineered steel structures as a construction method.

- Q: What are the design considerations for steel transmission towers?

- When designing steel transmission towers, several key considerations need to be taken into account to ensure their structural integrity, reliability, and efficient performance. These design considerations can be categorized into various aspects, including the tower's load capacity, material selection, structural design, and environmental factors. 1. Load Capacity: Steel transmission towers must be designed to withstand the loads they will experience throughout their lifespan. This includes dead loads (the weight of the tower structure and its components), live loads (such as wind, ice, and earthquake loads), and dynamic loads (such as those induced by conductor movement or line faults). The tower's design should account for these loads to prevent structural failure and ensure long-term stability. 2. Material Selection: Steel is commonly used for transmission towers due to its strength, durability, and cost-effectiveness. When selecting the type of steel, factors such as yield strength, ductility, and corrosion resistance should be considered. The choice of steel grade and protective coatings can enhance the tower's resistance to environmental conditions, such as corrosion in coastal or industrial areas. 3. Structural Design: The structural design of steel transmission towers involves determining the appropriate size, shape, and configuration of the tower components to meet the load requirements. The tower's height, base width, leg profile, and cross-sectional shape should be optimized to ensure stability, minimize material usage, and facilitate ease of construction. The design should also consider factors such as tower grounding, foundation design, and the connection between tower segments. 4. Environmental Factors: Steel transmission towers are exposed to various environmental conditions that can affect their performance. Wind is a critical factor, and towers must be designed to withstand wind speeds based on local regulations and site-specific conditions. Ice accumulation is another consideration in colder climates, as it can increase the load on the tower. Environmental factors such as temperature variations, seismic activity, and soil conditions should also be evaluated during the design process. 5. Maintenance and Inspection: Design considerations should also account for ease of maintenance and inspection. Access points, ladder systems, and platforms should be included to allow for safe and efficient tower inspections and repairs. Designing towers with suitable maintenance provisions can help extend their service life and minimize downtime. In conclusion, the design considerations for steel transmission towers encompass load capacity, material selection, structural design, environmental factors, and maintenance requirements. By carefully addressing these considerations, engineers can create robust and reliable transmission towers that meet the needs of the electrical grid while ensuring public safety and minimizing operational costs.

- Q: How are steel structures designed for transportation hubs?

- Steel structures for transportation hubs are designed with a focus on durability, efficiency, and safety. The design process involves considering factors such as the weight and volume of people and vehicles passing through, as well as the need for large open spaces and clear sightlines. Additionally, these structures must support heavy loads, withstand environmental conditions, and allow for flexible layouts to accommodate changing transportation needs.

- Q: How are steel structures used in parking garages and carports?

- Steel structures are commonly used in parking garages and carports due to their durability and strength. Steel provides a reliable framework that can support heavy loads, ensuring the safety of vehicles and people. It allows for the construction of large open spaces without the need for excessive columns or support walls, maximizing the usable area. Additionally, steel structures are resistant to weather conditions and require minimal maintenance, making them ideal for outdoor applications like parking garages and carports.

- Q: What are the considerations for steel structure design in coastal areas?

- When designing steel structures in coastal areas, several considerations need to be taken into account. Firstly, the corrosive effects of saltwater and airborne salts are significant. Therefore, the selection of corrosion-resistant materials and protective coatings is crucial to ensure the longevity and durability of the structure. Secondly, the high wind loads and potential for hurricanes or cyclones in coastal areas require the steel structure to be designed to withstand these extreme weather conditions. This includes adequate bracing, anchoring, and connections to resist lateral forces. Thirdly, the proximity to the ocean means that the structure may be exposed to high levels of moisture and humidity. Proper ventilation and drainage systems should be incorporated to prevent the accumulation of moisture and subsequent corrosion. Additionally, the design of steel structures in coastal areas should consider potential wave impact and flooding. Ensuring the foundation is built above the flood level and incorporating design features to redirect or absorb wave energy can help mitigate any potential damage. Lastly, environmental factors such as marine life and saltwater spray should also be considered. Design elements that deter marine growth and protect against saltwater ingress, such as coatings and sacrificial anodes, may be necessary. Overall, the considerations for steel structure design in coastal areas revolve around corrosion resistance, wind load resistance, moisture control, wave impact and flooding protection, and protection against marine life and saltwater spray.

- Q: How are steel structures used in oil and gas facilities?

- Steel structures are extensively employed in the oil and gas industry due to their robustness, potency, and ability to withstand harsh environmental conditions. They play a pivotal role in supporting different components and equipment within these facilities. One of the primary uses of steel structures in oil and gas facilities is for constructing storage tanks. These tanks are utilized for storing crude oil, refined petroleum products, and natural gas. Steel provides the necessary strength and structural integrity to endure the immense pressure and weight of the stored substances, ensuring their safety and preventing any leakage. Additionally, steel structures are employed in the construction of offshore platforms and drilling rigs. Offshore platforms are typically situated in challenging marine environments, exposed to extreme weather and corrosive saltwater. Steel, particularly corrosion-resistant alloys, is the ideal material choice for these structures as it offers exceptional resistance to corrosion and provides the requisite strength to support drilling equipment and personnel. Moreover, steel structures are utilized for constructing pipelines and pipe racks in oil and gas facilities. Pipelines are used for transporting oil, gas, and other fluids over long distances. Steel pipes are renowned for their high strength-to-weight ratio, which makes them suitable for withstanding the internal pressure and external loads that pipelines are subjected to. Furthermore, steel structures are also employed for constructing support buildings, compressor stations, and various other infrastructure within oil and gas facilities. These structures offer a secure and reliable framework for equipment installation, maintenance, and operation. Overall, steel structures are indispensable in oil and gas facilities as they provide the necessary strength, durability, and resistance to environmental conditions required for the safe and efficient operation of these facilities.

- Q: How are steel roof trusses designed?

- Computer-aided design (CAD) software and structural engineering principles are typically employed in the design of steel roof trusses. The design process consists of several essential steps. To begin with, the engineer determines the loads that the trusses will encounter, such as dead loads (the weight of the roof itself), live loads (such as snow or wind), and any project-specific additional loads. This information is then used to calculate the required strength and stiffness of the trusses. Subsequently, an appropriate truss configuration is selected based on factors like span length, desired roof slope, and aesthetic preferences. Common truss configurations include pitched trusses, parallel chord trusses, and bowstring trusses. Once the configuration is chosen, the size and spacing of the truss members, including the top and bottom chords, vertical and diagonal members, and any additional bracing, are determined by the engineer. These determinations rely on the calculated loads, as well as relevant design codes or standards. The engineer then performs structural analysis calculations to ensure the trusses can safely support the anticipated loads. This involves examining factors such as bending, shear, and deflection. Adjustments may be made to the truss design if necessary to ensure structural integrity. After the design is finalized, detailed construction drawings are created, which include plans, elevations, and sections. These drawings contain all the necessary information for fabrication and installation, including the dimensions and specifications of each truss member. In conclusion, the design of steel roof trusses requires careful consideration of loads, truss configuration, member sizing, and structural analysis. This ensures that the trusses are both structurally sound and capable of meeting the project's specific requirements.

- Q: How do steel structures contribute to sustainable development?

- Steel structures contribute to sustainable development in several ways. Firstly, steel is a highly recyclable material, which means that it can be reused without losing its inherent properties. This reduces the demand for new steel production and minimizes the environmental impact of mining and extraction processes. Additionally, steel structures are known for their durability and strength, allowing them to have a longer lifespan and requiring less maintenance. This leads to reduced energy consumption and lower greenhouse gas emissions over time. Moreover, steel is a lightweight material, which means that it requires fewer resources for transportation and installation. Lastly, steel structures can be designed to be energy-efficient, incorporating features such as insulation, solar panels, and natural lighting, which further contribute to sustainable development by reducing energy consumption and promoting renewable energy sources.

- Q: How are steel structures designed for crane loads and heavy equipment?

- Steel structures designed to withstand crane loads and heavy equipment undergo meticulous engineering to guarantee their ability to bear the required loads and function safely. The design process encompasses various factors, including the crane or equipment's weight, dimensions, the type of loads it will handle, and potential dynamic forces it may encounter. To begin with, the structural engineer conducts a thorough analysis of the loads the steel structure will face. This involves determining the crane or equipment's maximum weight and dimensions, as well as any potential loads it may carry or exert. Additionally, the engineer considers the impact of dynamic forces like wind or seismic activity, which can significantly impact the stability and safety of the structure. Based on this analysis, the engineer determines the necessary strength and stiffness of the steel members comprising the structure. This entails selecting suitable steel grades and sizes to ensure the structure possesses adequate load-bearing capacity and can withstand any bending, buckling, or shear forces that may arise during operation. Furthermore, the engineer meticulously designs the connections between the steel members to ensure they can efficiently transfer loads and maintain the overall stability of the structure. These connections must be able to withstand the expected forces, including the vertical and horizontal loads imposed by the crane or equipment. The design process also takes into account potential dynamic effects that may occur during crane or equipment operation. For instance, sudden starts, stops, or changes in direction can generate additional forces on the structure, which must be considered to uphold its integrity and safety. Moreover, the engineer may incorporate additional measures to enhance the structure's safety, such as providing adequate bracing or reinforcing specific members to prevent excessive deflection or deformation. Protective measures like anti-corrosion coatings or fire-resistant materials may also be considered to extend the structure's lifespan and durability. Overall, designing steel structures for crane loads and heavy equipment necessitates a comprehensive analysis of loads, careful selection of steel members and connections, and consideration of dynamic effects and safety measures. Through this rigorous design process, steel structures can be constructed to withstand the demanding requirements of crane operations and heavy equipment, ensuring the overall system's safety and efficiency.

Send your message to us

equilateral H type steel, galvanized Z type steel, solar stent type Z steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 8000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords