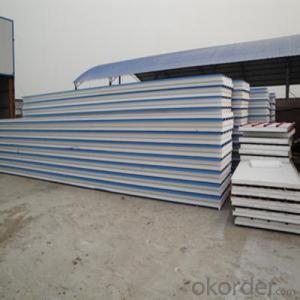

EPS roof sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPS sandwich panel production process adopts the colored steel plate as surface board, and the core material is the self-extinguishing closed cell polystyrene foam, It is a kind of high-strength composited building materials, and it was formed in the automated continuous molding machine, by combining the pressed colored steel with the High Strength Adhesives. It has the characteristics of complete insulation and fire-proof, fast construction speed, durability, and beautiful appearance, etc.

The above sandwich panels have been widely used in warehouses, factories, exhibition hall, prefabricated house, container houses and other industrial and civil buildings

One: Technical Specifications

1.Density: 8-24 kg/m3

2.Coefficient of thermal conductivity:k=0.025W/m.k

3.Compressive strength: 2.0 kg/cm2

4.Dimensional stability under low tempeaturelinear change rate,-25.24hr: 1.0,%

5.Water absorptionV/V,24hr:,30%

6.Fire retardance (Oxygen index) 26 B2 Grade

Two: Specification:

Steel sheet: up/bottom 0.3-0.6mm,colored steel plate, pained and galvanized

Insulated material: polyurethane (PU), Density: 10-30 kg/m3

Style: H- style board, match board

Width: match board, 950mm,960mm,1150mm (Effective width)H- style board, 1000mm,1200mm (Effective width)

Thickness: match board, 30-200mm; H-style board, 25-100mm

Length: According to the requirements and transportation terms

Color: According to the requirements (Regular color is White Gray, Navy)

- Q: What are the different types of connections used in steel structures?

- There are several types of connections used in steel structures, including bolted connections, welded connections, and riveted connections. Bolted connections involve using bolts to connect steel members together, providing flexibility for disassembly and maintenance. Welded connections involve fusing steel members together using heat, creating a strong and permanent connection. Riveted connections involve using metal rivets to connect steel members, providing a strong and reliable connection. Each type of connection has its advantages and is used based on the specific requirements and design considerations of the steel structure.

- Q: What are the design considerations for steel disaster-resistant buildings?

- Some key design considerations for steel disaster-resistant buildings include: 1. Structural robustness: The building should be designed to withstand extreme forces, such as strong winds, earthquakes, or explosions. Steel offers high strength and ductility, making it an ideal material for withstanding these forces. 2. Redundancy: Incorporating redundancy in the structural system ensures that even if one component fails, the building can still bear loads and remain stable. This can be achieved through redundant steel framing or by integrating alternative load paths. 3. Connection design: Properly designed connections between steel members are crucial to ensure the overall stability and resistance of the building. Connections should be able to withstand the anticipated forces and maintain their integrity during a disaster. 4. Fire resistance: Steel buildings should be designed to resist the effects of fire, as fires can weaken the structural integrity of steel. Fire-resistant coatings or insulation can be applied to protect the steel from high temperatures and prolong its load-bearing capacity. 5. Flexibility and ductility: Steel structures should be designed to be flexible and ductile, allowing them to absorb and dissipate energy during a disaster. This helps to mitigate the potential for sudden and catastrophic failure. 6. Adequate foundation design: A strong and well-designed foundation is essential for disaster-resistant steel buildings. The foundation should be able to resist both vertical and lateral loads, ensuring the stability of the entire structure. 7. Seismic design: In earthquake-prone regions, special attention should be given to seismic design considerations. Steel buildings should be designed to resist lateral forces and ground motion, incorporating seismic dampers or energy dissipation devices when necessary. By considering these factors, designers can create steel buildings that are capable of withstanding various disasters, safeguarding lives and minimizing damage.

- Q: What are the considerations for steel structure design in mountainous areas?

- When it comes to designing steel structures in mountainous areas, there are several important factors that need to be considered. These factors include: 1. Topography: The distinctive topography of mountainous regions presents challenges for designing steel structures. The steep slopes, uneven terrain, and varying elevations necessitate careful planning and engineering to ensure the stability and durability of the structure in the face of natural forces. 2. Seismic activity: Mountainous areas are often prone to seismic activity, such as earthquakes. Therefore, steel structures in these regions must be designed to withstand shaking and ground motion. This involves incorporating seismic design principles, such as proper connections, flexible structural systems, and accounting for potential liquefaction or landslides. 3. Snow loads: Mountainous areas typically experience heavy snowfall, especially at higher elevations. Therefore, the design of steel structures in these regions must take into account the additional load imposed by snow on the roof and other horizontal surfaces. Factors such as snow accumulation, wind drift, and the shape of the structure must be considered to avoid excessive snow buildup and potential collapse. 4. Wind loads: Mountainous areas are also susceptible to strong winds, particularly in exposed locations or at higher altitudes. To resist these wind loads, steel structures need to be designed with factors like wind speed, direction, and structure shape in mind. This may involve adding extra bracing, strengthening connections, or utilizing aerodynamic design features. 5. Temperature variations: Mountainous areas often experience significant temperature fluctuations, with colder temperatures at higher elevations. Therefore, steel structures must be designed to withstand these changes, which can cause the material to expand and contract. Proper consideration of thermal expansion and contraction, as well as the selection of suitable materials, is crucial to ensure the structural integrity of the steel components. 6. Environmental impact: Building in mountainous areas necessitates careful consideration of the surrounding environment. This includes minimizing the impact on natural habitats, preserving water bodies, and preventing soil erosion. Designing steel structures with minimal disruption to the natural landscape and utilizing sustainable construction practices can help mitigate the environmental impact. In conclusion, designing steel structures in mountainous areas requires a comprehensive understanding of the unique challenges posed by topography, seismic activity, snow loads, wind loads, temperature variations, and environmental impact. By carefully considering these factors, engineers can create structures that are safe, resilient, and harmonious with the natural environment.

- Q: What are the different types of steel finishes used in structures?

- There are various types of steel finishes used in structures, each offering unique properties and aesthetics. Some of the most commonly used steel finishes include: 1. Hot-dip galvanized: This process involves immersing the steel in a bath of molten zinc, resulting in a durable and corrosion-resistant finish. Hot-dip galvanizing is commonly used in outdoor structures, such as bridges and guardrails, as it provides excellent protection against rust and weathering. 2. Powder-coated: Powder coating is a dry finishing process where a powdered polymer is applied to the steel surface and then heated to form a protective layer. This finish offers a wide range of colors and textures, making it popular for architectural applications and decorative elements. 3. Brushed or satin finish: This type of finish is achieved by brushing the steel surface with abrasive materials, resulting in a dull and textured appearance. Brushed finishes are commonly used in interior applications, such as handrails and elevator panels, as they offer a sleek and contemporary look. 4. Polished finish: Polished steel finishes involve buffing the surface to a smooth and reflective appearance. This finish is often used in decorative elements, such as sculptures or stainless steel appliances, as it provides an elegant and high-end aesthetic. 5. Blackened finish: Blackening is a chemical process that creates a darkened surface on steel. This finish is commonly used in architectural applications to achieve a modern and industrial look. It also provides some level of corrosion resistance. 6. Electropolished finish: Electropolishing is an electrochemical process that removes a thin layer of metal to create a smooth and polished surface. This finish is typically used in applications where sanitary and hygienic conditions are required, such as in the food and pharmaceutical industries. These are just a few examples of the different types of steel finishes used in structures. The choice of finish depends on factors such as the desired appearance, functionality, and environmental conditions the steel will be exposed to.

- Q: Can steel structures be designed with architectural features?

- Yes, steel structures can be designed with architectural features. Steel is a versatile material that allows for great flexibility in design. It can be shaped, curved, and manipulated to create various architectural elements such as arches, domes, cantilevers, and intricate facades. Steel's strength and durability make it ideal for incorporating architectural features into structural designs, enabling architects to combine functionality with aesthetic appeal in their projects.

- Q: What are the common challenges in designing steel structures?

- Designing steel structures can come with its fair share of challenges. Some of the common challenges faced by engineers and designers include: 1. Structural Integrity: Ensuring the structural integrity of a steel structure is crucial. The design must be able to withstand the loads and forces it will encounter throughout its lifespan, such as wind, earthquakes, and heavy loads. Calculating and predicting these forces accurately can be challenging. 2. Material Selection: Choosing the appropriate steel grade and quality is essential. Different steel grades have different properties and strengths, and selecting the wrong grade can compromise the structure's safety and durability. The designer must consider factors such as corrosion resistance, toughness, and weldability when selecting the steel. 3. Connection Design: Properly designing and detailing the connections between different steel members is critical. Connections must be strong enough to transfer loads efficiently without compromising the overall structural stability. Designers need to consider factors like forces, moments, and tolerances during connection design. 4. Fabrication and Construction Constraints: The design of a steel structure must consider the limitations and capabilities of the fabrication and construction processes. Challenges may arise in terms of transportation, site access, construction sequence, and the availability of skilled labor. Designers must work closely with fabricators and constructors to address these issues. 5. Cost Optimization: Steel structures can be cost-effective, but optimizing costs without compromising safety and functionality can be challenging. Balancing factors such as material quantity, member sizes, and fabrication complexity while still meeting design requirements requires careful consideration. 6. Aesthetics and Architectural Integration: Designing steel structures that are visually appealing and harmonize with the surrounding environment can be a challenge. Balancing structural requirements with architectural intent, such as creating open and flexible spaces, can be complex and may require innovative design solutions. 7. Sustainability: In today's world, designing sustainable structures is essential. Incorporating energy-efficient features, using recyclable materials, and minimizing the carbon footprint are significant challenges in steel structure design. In conclusion, designing steel structures involves overcoming challenges related to structural integrity, material selection, connection design, fabrication and construction constraints, cost optimization, aesthetics, and sustainability. Engineers and designers must carefully consider these factors to create safe, functional, and visually pleasing steel structures.

- Q: How are steel structures designed to accommodate signage and wayfinding systems?

- Signage and wayfinding systems often rely on steel structures due to their strength, durability, and versatility. When designing these structures, several factors are taken into account to ensure effective integration and functionality. To begin with, the load-bearing capacity of the steel structure is assessed to determine its ability to support signage and wayfinding systems. This includes considering the weight and dimensions of the signage, as well as any additional components like lighting or directional arrows. It is important to ensure that the steel structure can adequately support these elements without compromising its structural integrity. The location and positioning of the signage and wayfinding systems are also carefully planned to maximize visibility and accessibility. Different mounting options, such as brackets, frames, or clamps, can be used to securely hold the signage in place. The size and orientation of the signage are also considered to ensure easy comprehension by pedestrians or drivers. Furthermore, the design of the steel structure takes into account the aesthetics of the signage and wayfinding systems. Customization options like finishes, colors, or textures can be utilized to complement the overall design theme or branding of a specific location. This ensures that the signage seamlessly blends into its surroundings and enhances the visual appeal. In terms of maintenance and accessibility, steel structures are designed to allow for easy installation, removal, and replacement of signage and wayfinding systems. Access panels, hatches, or removable sections can be incorporated into the design to facilitate maintenance and ensure easy updates or repairs. Safety considerations are paramount when designing steel structures for signage and wayfinding systems. Proper installation techniques, including secure fasteners, are used to prevent the signage from becoming loose or falling. Additionally, measures are taken to avoid obstructing visibility or posing hazards to pedestrians or vehicles nearby. Overall, steel structures are carefully designed to accommodate signage and wayfinding systems by considering load-bearing capacity, visibility, aesthetics, maintenance, and safety. By integrating these factors, steel structures provide a reliable and sturdy framework for effective communication and guidance in various environments.

- Q: How are steel structures designed for efficient use of water and waste resources?

- Steel structures can be designed in a way that promotes efficient use of water and waste resources through several key strategies. Firstly, water-efficient fixtures and systems can be incorporated into the design of steel structures. This includes the use of low-flow toilets, faucets, and showerheads, as well as efficient irrigation systems for landscaping purposes. By implementing these water-saving measures, the overall water consumption of the structure can be significantly reduced, leading to less strain on local water resources. Additionally, steel structures can be designed to capture and reuse rainwater. This can be achieved by installing rainwater harvesting systems, which collect and store rainwater for later use. This water can then be used for non-potable purposes such as irrigation, toilet flushing, or even cooling systems. By utilizing rainwater, the demand for freshwater can be reduced, promoting sustainable water use. In terms of waste resources, steel structures can be designed to minimize construction waste through efficient building practices. This includes the use of prefabricated steel components that are precisely manufactured off-site, reducing the amount of waste generated during construction. Furthermore, steel structures can be designed with the intention of maximizing recycling opportunities. Steel is a highly recyclable material, and by incorporating design features that facilitate the disassembly and recycling of the structure at the end of its life cycle, valuable resources can be conserved and waste minimized. Lastly, the energy efficiency of steel structures can indirectly contribute to the efficient use of water and waste resources. By utilizing energy-efficient systems and insulation, steel structures can reduce their overall energy consumption. This, in turn, reduces the demand for energy production, which often relies heavily on water resources and can generate significant waste. By lowering energy demand, steel structures indirectly promote the efficient use of water and waste resources associated with energy production. In conclusion, steel structures can be designed with various strategies to promote the efficient use of water and waste resources. From incorporating water-efficient fixtures and rainwater harvesting systems to minimizing construction waste and maximizing recycling opportunities, steel structures can contribute significantly to sustainable resource management.

- Q: How are steel structures used in temporary and modular buildings?

- Steel structures are widely used in temporary and modular buildings due to their strength, durability, and versatility. Temporary and modular buildings are often required in situations where there is a need for quick and efficient construction, such as disaster relief, construction sites, and events. Steel structures provide a solid framework that can be easily assembled and disassembled, making them ideal for temporary and modular buildings. The use of steel ensures that these structures can withstand various weather conditions and offer a stable and secure environment. In temporary buildings, steel structures are commonly used for the main framework, walls, and roof. The steel framework provides the necessary structural support, while the walls and roof can be made from steel panels or other materials that can be easily attached and detached as needed. This allows for quick assembly and disassembly, making temporary buildings highly portable and adaptable. Modular buildings, on the other hand, are constructed by assembling pre-fabricated steel modules. These modules are built off-site and can be easily transported to the desired location. Once on-site, the modules are connected to form a complete building. The use of steel ensures that these modules are robust and can be easily transported without any damage. Steel structures also offer flexibility in terms of design and customization. They can be easily modified or expanded to meet specific requirements. This is especially beneficial for temporary and modular buildings, as they can be tailored to fit different purposes and sizes. Furthermore, steel structures are known for their sustainability. Steel is a recyclable material, making it an environmentally friendly choice. It can be reused in future construction projects, reducing waste and promoting a circular economy. In conclusion, steel structures are essential in temporary and modular buildings due to their strength, durability, versatility, and sustainability. They provide a solid framework that allows for quick assembly and disassembly, making these buildings highly portable and adaptable. Steel structures also offer flexibility in design and customization, ensuring that these buildings can be tailored to specific needs.

- Q: What are the factors to consider when designing steel structures for retail and commercial spaces?

- When designing steel structures for retail and commercial spaces, there are several factors that need to be considered. These factors include the following: 1. Load requirements: The primary consideration in designing steel structures is to ensure that they can support the anticipated loads. This includes the weight of the building itself, as well as the weight of the contents and any additional loads such as HVAC systems or machinery. The structural engineer must calculate the required load-bearing capacity of the steel components to ensure they can withstand the expected loads. 2. Building codes and regulations: Compliance with local building codes and regulations is crucial to ensure the safety and structural integrity of the steel structure. The design must meet all relevant codes, including requirements for fire resistance, seismic design, wind loads, and accessibility. 3. Flexibility and adaptability: Retail and commercial spaces often require flexibility and adaptability to accommodate changing needs and layouts. The steel structure should be designed to allow for future modifications or expansions without compromising its stability or integrity. This can include provisions for adjustable partitions, removable walls, or flexible floor plans. 4. Architectural aesthetics: The design of retail and commercial spaces is not only about functionality but also about creating an appealing environment for customers and employees. Steel structures can offer a wide range of architectural possibilities, allowing for unique and aesthetically pleasing designs. Factors such as the type of steel used, the finishes, and the integration of other materials should be considered to achieve the desired visual impact. 5. Cost-effectiveness: Steel structures are known for their cost-effectiveness in terms of construction time and material efficiency. However, it is important to consider the overall project budget when designing steel structures for retail and commercial spaces. The design should aim to optimize cost without compromising safety or functionality. 6. Energy efficiency: With the growing emphasis on sustainability, energy efficiency should also be a factor to consider. Steel structures can be designed to incorporate insulation, efficient HVAC systems, and natural lighting, reducing energy consumption and operating costs. 7. Maintenance and durability: Retail and commercial spaces often experience high traffic and require regular maintenance. The design should consider factors that facilitate easy maintenance and durability, such as corrosion-resistant coatings, accessible service routes, and durable finishes. In conclusion, designing steel structures for retail and commercial spaces requires careful consideration of load requirements, building codes, flexibility, aesthetics, cost-effectiveness, energy efficiency, and maintenance. By taking into account these factors, architects and engineers can create safe, functional, and visually appealing spaces that meet the specific needs of their clients.

Send your message to us

EPS roof sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords