EPDM Rubber Waterproofing Membrane Underground

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

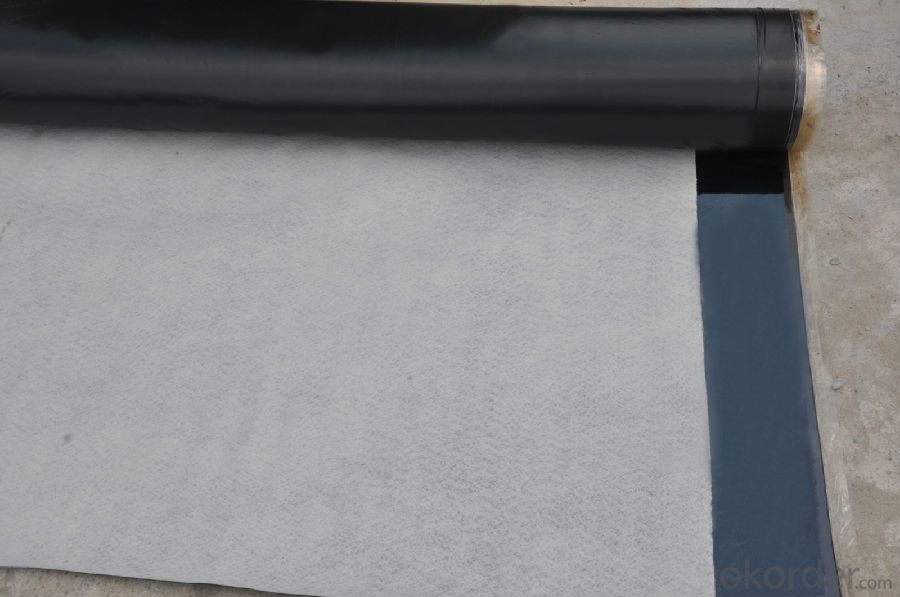

Introduction for EPDM Waterproofing Membrane:

Waterproof membrane for roof adopt the international advanced level cold feed extrusion continuous vulcanization process for the integration of production equipment and technology so that the system density of products is better and the products have no bubble sooth surface, no performance difference between vertical and horizontal.

Characteristic of EPDM Waterproofing Membrane:

· with adhesive tape on the overlap for the sealing of junction,convention for application.

· Excellent weather resistance, corrosion resistance, anti-aging, antioxidant.

· Excellent waterproofing performance and encase nail holes.

· Good permeability, can be in damp base surface construction, make the maintenance structure internal water vapor rapidly eduction, avoid effectively mould and condensing formation

Excellent tensile strength and elongation.

· large Surface friction, grass-roots closely.

no smell,no taste,accord with environmental protection requirements.

Specification of EPDM Waterproofing Membrane:

No. | Item | Unit | Standard Request | |

1 | Variation in Dimension | Thickness | % | ±10 |

Width | % | ±1 | ||

Length | % | No Negative Value | ||

2 | Tensile Strength at Break(Normal Temperature) | Mpa | ≥7.5 | |

Tensile Strength at Break(60ºC) | Mpa | ≥2.3 | ||

3 | Elongation at Break(Normal Temperature) | % | ≥450 | |

Elongation at Break(-20ºC) | % | ≥200 | ||

4 | Tearing Strength | KN/m | ≥25 | |

5 | Water Impermeability(30min) | * | 0.3Mpa Impermeability | |

6 | Bend Temperature | ºC | ≤-40 | |

7 | Heating Expansion/Shrinkage | Expansion | mm | ≤2 |

Shrinkage | mm | ≤4 | ||

8 | Hot Air Aging 80ºC x168h | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

9 | Property of Anti Alkali 10% Ca(OH)²x 168h normal temperature | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥80 | ||

10 | Elongation 40%,500x102 | * | No Crack | |

11 | Artificial Aging | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

Appearance of 100% elongation | * | No Crack | ||

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Are waterproofing membranes resistant to earthquake-induced water pressure?

- Waterproofing membranes may offer some level of resistance against water pressure caused by earthquakes; however, their effectiveness may vary depending on the specific membrane and the magnitude of the earthquake. The primary purpose of waterproofing membranes is to create a barrier that prevents water infiltration and protects the structure from water damage. However, they are not explicitly engineered to withstand the pressure exerted during earthquakes. During seismic activity, the ground undergoes significant shaking and movement, resulting in increased water pressure in the surrounding soil and groundwater. This heightened pressure can potentially breach the waterproofing membrane, compromising its efficacy. To enhance the resistance of waterproofing membranes to earthquake-induced water pressure, additional measures may be necessary. These measures can involve reinforcing the membrane with shock-absorbing materials, installing drainage systems to alleviate excessive water pressure, and ensuring proper installation and maintenance of the membrane. It is crucial to consult a professional waterproofing expert or structural engineer when selecting a suitable waterproofing system for earthquake-prone areas. These experts can provide guidance on choosing membranes explicitly designed to withstand higher water pressure and offer better protection against earthquakes.

- Q: What is the difference between SBS and APP rolls?

- Second, APP modified asphalt waterproofing membrane (polyester tire): Features: Good elasticity, heat resistance and resistance to UV aging; its softening point above 150 ℃; temperature range of use -15 ℃ ~ 130 ℃; good corrosion resistance, high self-ignition point (265 ℃); Low temperature performance slightly lower than the SBS waterproofing membrane; hot melt is very good, very suitable for hot melt construction. Scope: Compared with the SBS waterproofing membrane, in addition to the general use of the project, APP modified asphalt waterproofing membrane because of better heat resistance and has excellent resistance to UV aging, more suitable for high temperature hot or ultraviolet radiation Area of ??building waterproof.

- Q: Can a waterproofing membrane be applied over existing coatings?

- Indeed, it is feasible to apply a waterproofing membrane on top of current coatings. Nevertheless, it is crucial to acknowledge that the effectiveness of this process relies on various factors, including the state and compatibility of the existing coatings, the specific type of waterproofing membrane employed, and the preparation of the surface before application. It is advisable to seek advice and instructions from a professional or the manufacturer of the waterproofing membrane regarding the application procedure. Furthermore, a comprehensive examination of the current coatings should be performed to verify their quality and suitability for the application of the waterproofing membrane.

- Q: Can a waterproofing membrane be used on tunnels with emergency exits?

- Certainly! Waterproofing membranes can be applied to tunnels that have emergency exits. It is strongly advised to utilize a waterproofing membrane in these tunnels to prevent water infiltration and safeguard the integrity of the exits. These membranes are specifically designed to establish a barrier against water and moisture, guaranteeing that the tunnels stay dry and unharmed by water. This is particularly crucial for emergency exits, as they must remain accessible and operational under all circumstances. By installing a waterproofing membrane, the tunnels can be adequately shielded from potential water ingress, thus ensuring the safety and functionality of the emergency exits.

- Q: Can a waterproofing membrane be used in high-traffic areas?

- Yes, a waterproofing membrane can be used in high-traffic areas. These membranes are designed to provide a protective barrier against water and moisture, making them suitable for use in areas that experience heavy foot traffic. They are durable, resistant to wear and tear, and can help prevent water damage and leakage in such areas.

- Q: Can a waterproofing membrane be used in industrial facilities or warehouses?

- Yes, a waterproofing membrane can be used in industrial facilities or warehouses. Industrial facilities and warehouses often have concrete floors or walls that are susceptible to water damage from leaks or moisture. By applying a waterproofing membrane, these areas can be protected against water penetration, preventing potential damage to the structure and its contents. Waterproofing membranes are designed to create a barrier that prevents water from seeping through the surface, providing an effective solution for industrial facilities and warehouses where moisture control is essential. Additionally, these membranes are durable and can withstand heavy foot traffic and equipment, making them suitable for use in high-traffic areas. Overall, using a waterproofing membrane in industrial facilities or warehouses can help maintain a dry and safe environment, safeguarding the structure and its contents.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces. Waterproofing membranes are designed to protect surfaces from water penetration and damage. They are typically made of materials such as rubber, asphalt, or thermoplastic, which provide a barrier against moisture. Whether it is applied on interior walls, floors, or exterior foundations, roofs, or balconies, a waterproofing membrane can effectively prevent water from seeping through and causing potential issues like leaks, mold, or structural damage. It is important to consider the specific requirements of each surface and choose a waterproofing membrane that is suitable for the intended application.

- Q: SBS modified asphalt waterproofing membrane and synthetic polymer membrane the same, not the same, what is the difference?

- Polymer waterproofing membrane is a synthetic rubber, synthetic resin-based new waterproof membrane, with high elasticity, high tensile strength, elongation, heat resistance and low temperature flexibility, corrosion resistance, aging resistance, cold construction, Single-layer waterproof and long life and other advantages. Can be used cold sticky or self-adhesive construction

- Q: Can a waterproofing membrane be used in high-rise buildings?

- Yes, a waterproofing membrane can be used in high-rise buildings. It is commonly utilized in high-rise buildings to prevent water infiltration and protect the structure from potential damages caused by moisture. The membrane is applied to various surfaces such as roofs, foundations, and walls to create a barrier against water penetration, ensuring the building remains dry and structurally sound.

- Q: Can a waterproofing membrane be used for data centers?

- Using a waterproofing membrane in data centers is possible. The main purpose of a waterproofing membrane is to stop water from getting in, which is very important for safeguarding delicate equipment and crucial data in a data center. Water damage can lead to expensive periods of inactivity and data loss, so it is crucial to have dependable waterproofing measures in place. By applying a waterproofing membrane to the walls, floors, and ceilings of a data center, a barrier can be created to prevent water leaks and the buildup of moisture. This ensures that a controlled and dry environment is maintained, guaranteeing the safety and functionality of the data center's infrastructure and equipment. Furthermore, certain waterproofing membranes also provide insulation properties, further improving the protection and energy efficiency of the data center.

Send your message to us

EPDM Rubber Waterproofing Membrane Underground

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords